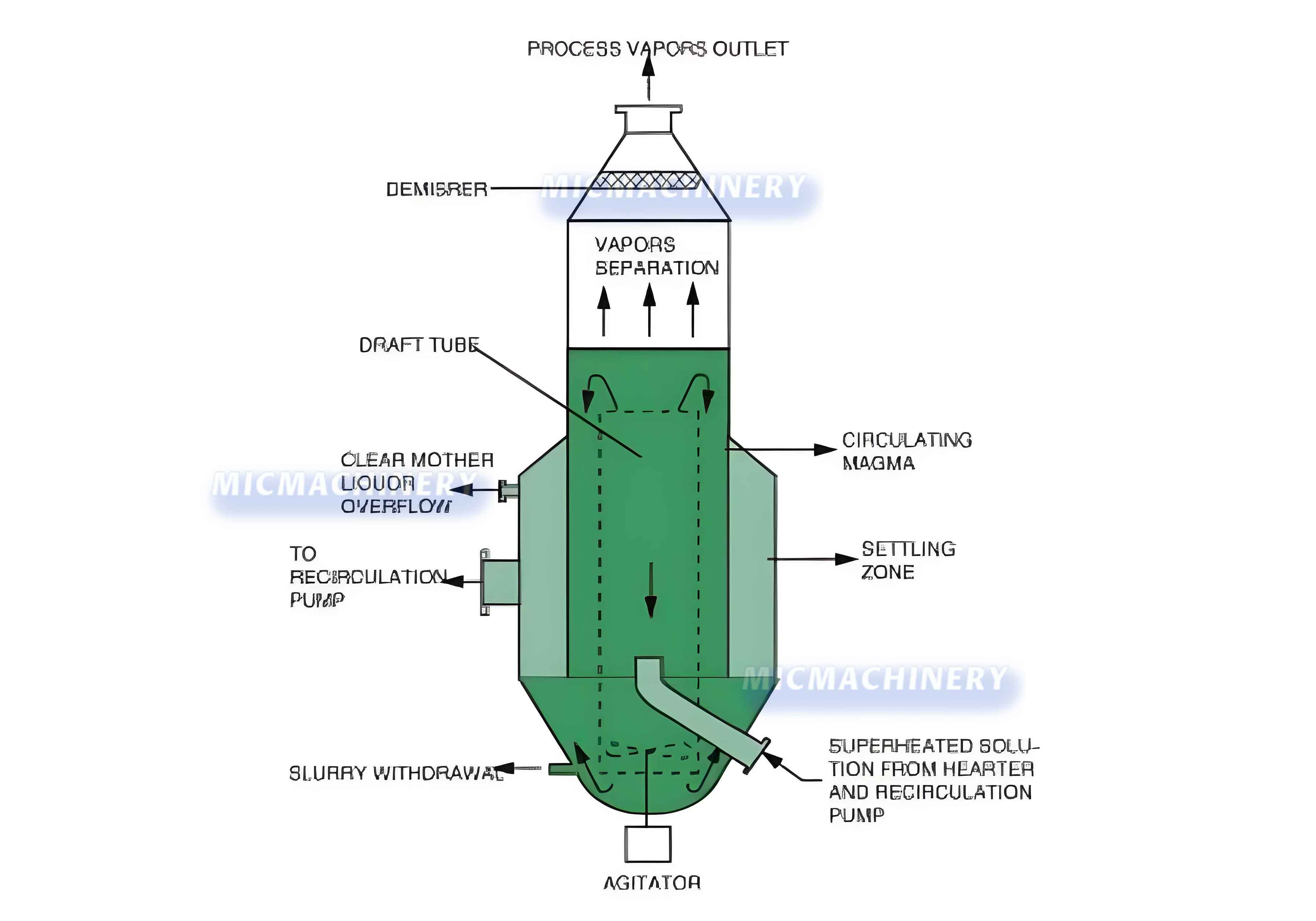

DTB Continuous Evaporation Crystallizer

Continuous Evaporation Crystallizer – Advanced Industrial Solution

The continuous evaporation crystallizer is a highly efficient system widely applied in industries such as pharmaceuticals, chemicals, food processing, and environmental protection. It is designed to achieve continuous evaporation and crystallization of various liquid solutions, offering superior heat transfer, stable operation, and uniform crystal size. With its advanced design, this system ensures not only excellent product quality but also significant savings in energy and operating costs.

High-Efficiency Performance

This continuous evaporation crystallizer operates under optimized conditions, enabling rapid evaporation and controlled crystallization. By maintaining precise temperature and flow parameters, it guarantees uniformity in crystal formation while reducing the risk of fouling and scaling. Its advanced configuration makes it suitable for handling heat-sensitive materials, ensuring product stability and preserving valuable compounds.

Reliable Manufacturing Standards

Built by a professional auxiliary machine manufacturer, the equipment is constructed with high-quality stainless steel and features advanced welding and polishing technology to meet strict hygiene and safety standards. Every unit undergoes rigorous quality testing, ensuring long-term durability, resistance to corrosion, and compliance with international cGMP requirements.

Seamless Integration as an Auxiliary System

As an essential auxiliary machine, the crystallizer integrates smoothly with other industrial equipment such as evaporators, dryers, and filtration systems. This flexibility makes it an indispensable part of modern production lines, boosting overall efficiency and ensuring continuous, uninterrupted workflow.

Intelligent Control and Automation

Equipped with an advanced automation system, the crystallizer allows real-time monitoring and control of critical parameters such as temperature, vacuum, and concentration levels. This ensures consistent product quality, reduces manual intervention, and enhances overall process safety.

Energy-Saving and Cost-Effective

Energy efficiency is at the core of the continuous evaporation crystallizer. Its innovative design minimizes steam consumption, maximizes heat recovery, and lowers operational expenses. By optimizing both energy use and production cycles, it provides companies with a sustainable and cost-effective solution.

Applications Across Industries

• Pharmaceuticals: Concentration and crystallization of active ingredients.

• Chemicals: Production of salts, resins, and specialty chemicals.

• Food Processing: Concentration of sugar, dairy, and other food solutions.

• Environmental Protection: Wastewater treatment and resource recovery.

Why Choose This Crystallizer?

• Built by a trusted auxiliary machine manufacturer with years of expertise.

• Functions as a versatile auxiliary machine in various industrial lines.

• Offers precise control, reliable operation, and superior durability.

• Designed for energy savings, cost reduction, and maximum output efficiency.