Falling Film Evaporator

Falling Film Evaporator

The falling film evaporator is an advanced liquid concentration system widely applied in the food, beverage, pharmaceutical, and chemical industries. Known for its efficiency, reliability, and energy savings, this equipment is designed to handle heat-sensitive materials with precision. It is an essential solution for businesses seeking high productivity and consistent results.

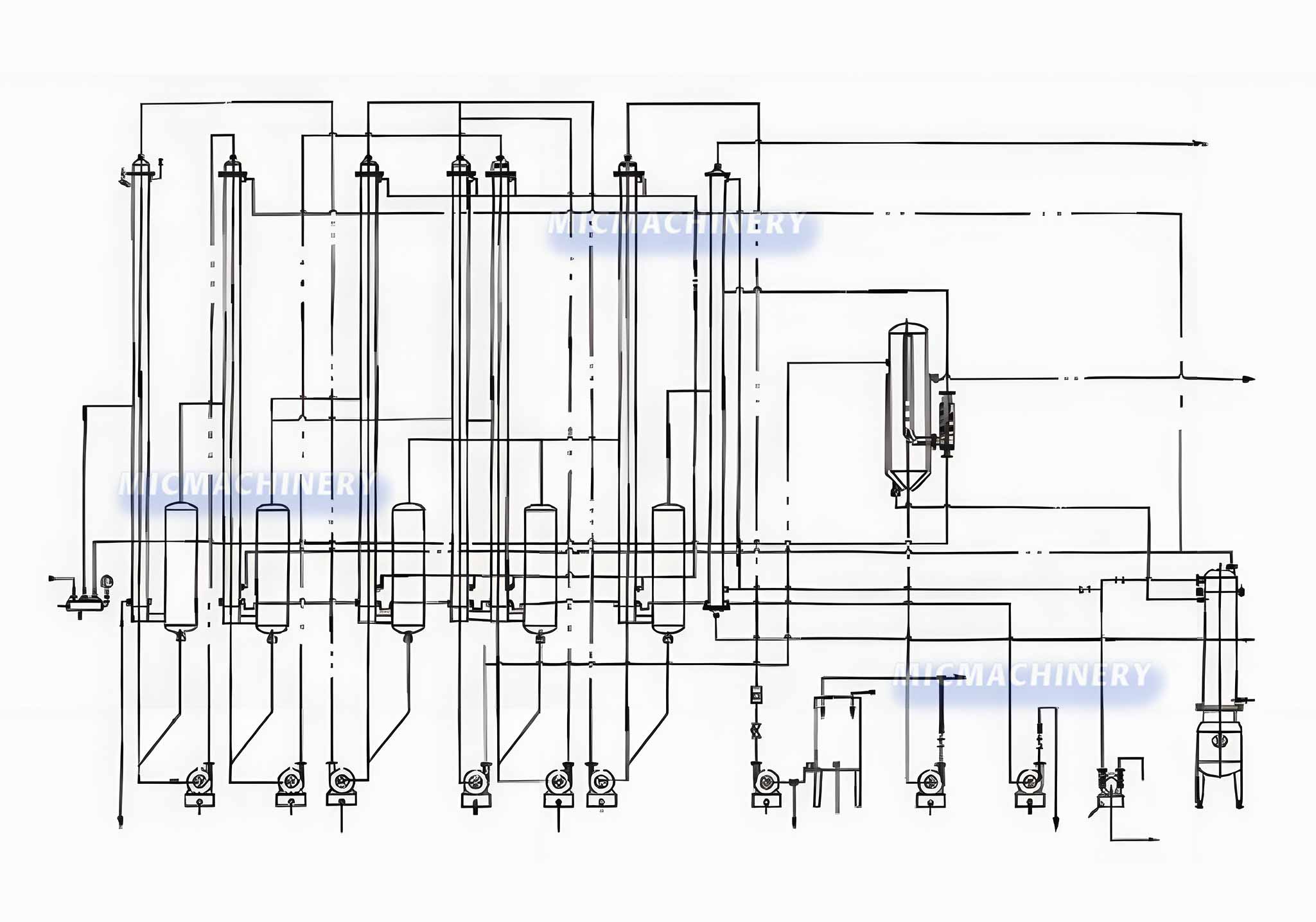

Falling Film Evaporator Working Principle

The falling film evaporator working principle is based on distributing liquid as a thin film along the inner walls of vertical heating tubes. As the liquid flows downward, heat transfer occurs rapidly, allowing evaporation to happen under controlled vacuum or atmospheric conditions. This ensures fast concentration, minimal thermal degradation, and stable product quality, making it suitable for temperature-sensitive substances such as juices, milk, herbal extracts, and solvents.

Durable Construction and Advanced Design

Built with high-grade stainless steel, the evaporator falling film guarantees long service life, corrosion resistance, and easy cleaning. Its vertical tubular structure minimizes scaling, reduces maintenance, and supports continuous operation. Automated temperature, pressure, and flow controls improve safety and efficiency, ensuring consistent output across industries.

Applications Across Industries

The falling film evaporator is widely used for:

• Food and Beverage: Concentration of juices, milk, and syrups

• Pharmaceutical: Herbal extractions, medicinal liquids, and active ingredients

• Chemical: Solvent recovery, liquid concentration, and industrial solutions

Trusted Falling Film Evaporator Manufacturers

We are among the leading falling film evaporator manufacturers, providing equipment that meets international standards. With years of expertise and advanced production capabilities, we deliver machines that are efficient, durable, and tailored to meet industry-specific needs.

Falling Film Evaporator for Sale

Our falling film evaporator for sale offers outstanding value with competitive pricing and dependable performance. Whether for small-scale or large-scale production, this equipment provides energy-saving benefits, reduced operational costs, and high return on investment.

Key Features

• Advanced falling film evaporator working principle for heat-sensitive liquids

• Stainless steel design for durability and hygiene

• Energy-efficient operation with reduced thermal damage

• Precision control systems for consistent results

• Cost-effective solutions from reliable falling film evaporator manufacturers

By choosing our falling film evaporator, you gain a reliable, energy-efficient solution backed by experienced falling film evaporator manufacturers. With competitive pricing and the availability of a high-quality falling film evaporator for sale, this system is the ideal choice for modern production lines requiring superior performance and long-term value.

| Model | Double-effect | Triple-effect | Four-effect | Five-effect |

| Water evaporating capacity (Kg/h) | 1200-4000 | 3600-15000 | 8000-50000 | 10000-65000 |

| Feed material density (%) | According to material | |||

| Discharge material density (%) | According to material | |||

| Steam pressure (Mpa) | 0.5-0.8 | |||

|

Steam consumption Kg/kg evaporation amount (with heat pressure pump) |

0.38 | 0.28 | 0.23 | 0.19 |

| Evaporating temperature (℃) | 45-90 | |||

| Sterilizing temperature (℃) | 90-110 | |||

|

Cooling water cost T/T evaporation amount (inputting water 20℃, outputting water 40℃) |

11 | 8 | 7 | 6 |