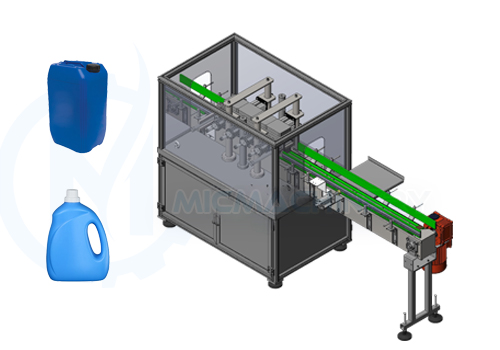

Internal Pressure Detector

The product, after being processed by the liquid nitrogen filling machine, features real-time pressure detection of cans, PET bottles, and other carbonated products post-filling. It can quickly detect and reject defective products, providing audible and visual alarms. Users can monitor the front-end equipment at any time to ensure normal operation, preventing defective products from reaching the market and causing adverse effects. Continuous rejection of defective products can trigger warnings for potential issues with the front-end equipment, and automatic shutdown of the front-end equipment can be set to minimize losses. Additionally, the system helps users adjust the liquid nitrogen filling amount without damaging the cans, ensuring proper internal pressure.

Design Basis

In the process of canned beverage packaging, quality defects arise in various stages due to the stability of production equipment and operator skill levels, leading to the generation of defective products, which negatively affect product quality. Common issues include:

| Serial Number | Quality Defects | Risks | Explanation |

| 1 | Loose sealing | Material leakage | Sealing machine issue |

| 2 | Damaged cap | Material leakage | Cap issue |

Currently, most manufacturers rely on manual inspection to control these risks, but manual inspection has significant limitations, such as:

| Serial Number | Drawbacks | Explanation |

| 1 | Easy to fatigue, leading to unstable accuracy | Highly affected by line speed |

| 2 | Low accuracy, uncertainty due to human factors | |

| 3 | Increasing labor costs |

As shown above, traditional manual inspection methods are ineffective for detecting various quality defects on the production line, making it challenging to control production risks effectively.

Solution

Based on the production process of beverage cans, automated detection equipment is installed at appropriate positions along the production line to perform online testing of each product and automatically reject defective ones. The list of equipment to be installed is as follows:

| Serial Number | Installation Location | Equipment Name |

| 1 | After filling and sealing | Pressure Detection Machine |

By installing automated detection equipment, quality control of each packaging stage is achieved, and defective products are rejected in real-time. In the event of abnormal production issues, the complete alarm system promptly alerts on-site operators, enabling immediate troubleshooting and ensuring production efficiency.

Advantages of Installing Online Detection Machines

| Serial Number | Advantages | Explanation |

| 1 | High speed, high efficiency | Effectively replaces a large number of manual inspections in high-speed production lines |

| 2 | High precision | Effectively addresses the accuracy issues of manual inspection |

| 3 | Reliability assurance | Overall equipment operation is more reliable than manual inspection |

| 4 | Production data management | Collects and analyzes production data, calculating product defect rates |

| 5 | Information management for the entire packaging line | Information management for the post-packaging process |

These advantages go beyond just detection, as advanced automated equipment should be a vital part of future smart factories, offering features like industrial Ethernet interfaces and multiple communication supports for easy upgrades to automation and networking.

Product Features

The monitoring system utilizes Siemens PLC and high-precision dynamic tracking sensors capable of detecting tiny pressure changes. The sensors send real-time data to the PLC, which then calculates and provides timely results. The system enables real-time monitoring of every tested product.

| Parameter | Specification |

| Rated Input Voltage | 220V/AC-50HZ |

| Current | ≤5A |

| Humidity | Relative humidity 0-100% |

| Operating Altitude | Can operate at altitudes up to 6050 meters |

| Noise | Continuous noise ≤78DB |

| Machine Weight | 200KG |

| Capacity | Speed 800/min |

| Applicable Products | Carbonated products (beer, carbonated drinks, liquid nitrogen products, PET bottles, etc.) |

| Component | Brand | Origin |

| PLC Controller | Siemens | Germany |

| Touch Screen | Xinje | China |

| Switching Power Supply | Mean Well | Taiwan |

| Solenoid Valve | Airtac | Taiwan |

| Cylinder | Airtac | Taiwan |

| Proximity Switch | Omron | Japan |

| Encoder | Omron | Japan |

| Analysis Software | Independently Developed | China |