MIC Juice Cup Packaging Machine (600-800PCS)

Introduction to Jiangsu Mic Machinery

Jiangsu Mic Machinery is a leading manufacturer of innovative and reliable packaging solutions, specializing in the food and beverage industry. With a strong commitment to quality and technology, we provide advanced machinery that enhances production efficiency while ensuring the highest standards of safety and hygiene. Our product range includes various automated filling, labeling, and packaging machines that cater to diverse production needs. We pride ourselves on offering solutions that meet the demands of businesses, both large and small, delivering customized systems designed to optimize operational efficiency and reduce costs.

Our MIC juice cup packaging machine is one of our flagship products, providing an efficient and automated solution for businesses looking to package fruit juices in cups at speeds of 600-800 pieces per hour. This machine combines advanced technology with ease of use to meet the growing demand for packaged fruit juices in the market.

|

|

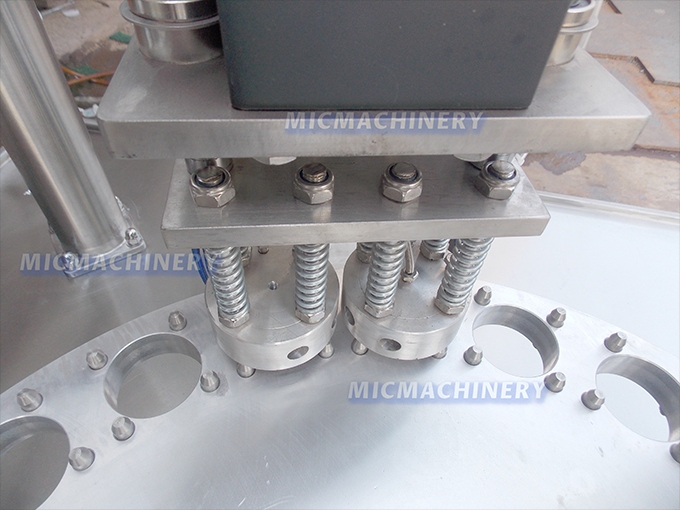

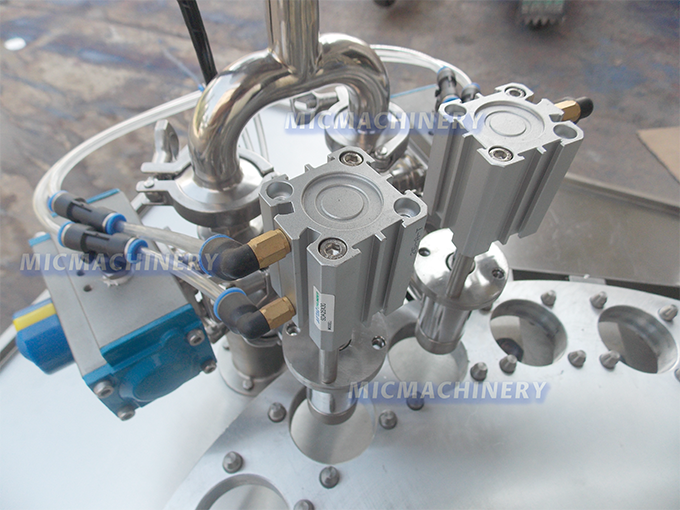

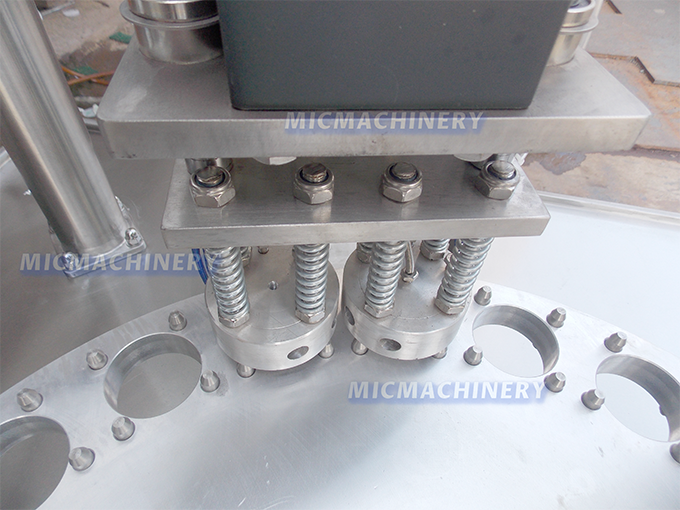

Filling station |

|

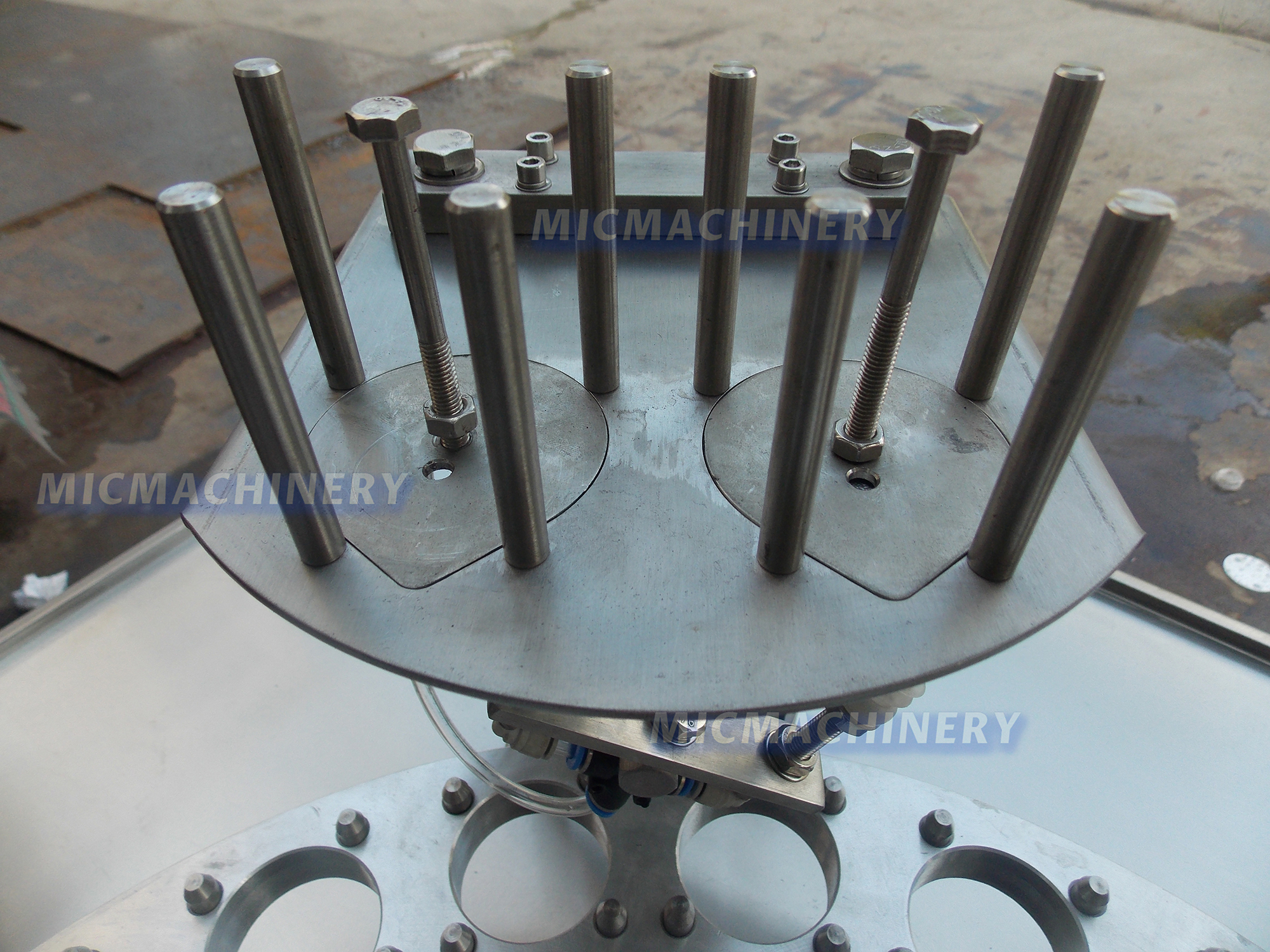

Foil loading rack

|

|

|

|

Foil sealing

|

Working Principle of the Juice Packing Machine

The fruit juice packing machine operates using an automated system designed to fill, seal, and package fruit juices into cups with high precision and efficiency. The process begins by automatically loading the cups into the packaging line. The machine then fills the cups with the desired amount of fruit juice, using a precise filling system to ensure accurate volume control.

Once the cups are filled, the machine uses a sealing mechanism to tightly seal the cups, preventing leakage and ensuring the juice remains fresh. The sealed cups are then transported through the system for labeling, packaging, and inspection. The entire process is fully automated, minimizing human intervention and reducing the chances of error. The machine operates at speeds of 600-800 cups per hour, making it suitable for small to medium-scale juice production lines.

Function and Advantages of the Juice Packaging Machine

1、High-Speed Operation

The automatic juice packing machine operates at an impressive speed of 600-800 cups per hour, allowing businesses to meet moderate production demands efficiently. This high throughput helps companies reduce production time while maintaining a consistent packaging quality.

2、Accurate Filling System

The machine features a highly precise filling system that ensures each juice cup is filled to the exact desired volume. This reduces waste, prevents overfilling, and ensures product consistency across all packages.

3、Sealing Efficiency

The juice cup packaging machine is equipped with an advanced sealing system that ensures each cup is sealed tightly, preventing leaks and ensuring the freshness of the fruit juice. The sealing mechanism is designed to handle various cup sizes and materials, providing flexibility for different packaging needs.

4、Fully Automated Process

The entire packing process, from cup loading to filling and sealing, is automated. This reduces the need for manual labor, lowers the risk of human error, and improves overall production efficiency. The user-friendly interface allows operators to easily adjust settings and monitor the entire process.

5、Hygienic and Safe

The fruit juice packing machine is designed with food-grade materials that meet international hygiene standards. Its easy-to-clean structure ensures that the packaging process remains sanitary and minimizes the risk of contamination, which is essential for food and beverage products.

6、Energy-Efficient Design

This machine is built to operate with minimal energy consumption, reducing operational costs and making it a more sustainable choice for businesses looking to improve their energy efficiency.

7、Compact and Space-Saving

The automatic juice packing machine is designed with a compact footprint, making it suitable for businesses with limited production space. Its efficient use of space allows it to be integrated seamlessly into existing production lines.

8、Versatility in Packaging

The machine is capable of handling various cup sizes and juice types, from concentrates to freshly squeezed juices. This versatility makes it ideal for businesses looking to offer a variety of fruit juice products in different packaging formats.

9、Durability and Reliability

Built with high-quality materials, the juice cup packaging machine is designed to withstand high-volume production. Its robust construction ensures long-lasting performance, making it a valuable investment for businesses focused on long-term growth.

In summary, the MIC juice cup packaging machine offers an efficient, reliable, and flexible solution for small to medium-scale juice producers. With its high-speed operation, precise filling and sealing, and fully automated process, this machine streamlines the fruit juice packaging process while ensuring product quality. Its compact design, energy efficiency, and versatility make it an excellent choice for businesses seeking to improve their packaging efficiency while maintaining the highest standards of safety and hygiene.

| Diameter | 1100*1100*1600mm |

| Weight | 350KGS |

| Power | 2 KW |

| Voltage | 110V/ 60Hz 1P |

| Air pressure | 0.6-0.8Mpa |

| Capacity | 600-800 pcs/hour |

| Air consumption | 0.6m³/min |

| Heating type | electrical heated |

| Working position | 6 |

| Machine frame | SUS 304 |

| Item | Brand |

| PLC | OMRON |

| Touch Screen | WEINVIEW |

| Motor | DINGYI |

| Magnetic Valve | JELPC |

| AC Contactor | SCHNEIDER |

| Temperature Control | SIMP |

| Relay, Circuit Breaker | DELIXI |

| Divider | REP |

| Pneumatic Component | AKS |