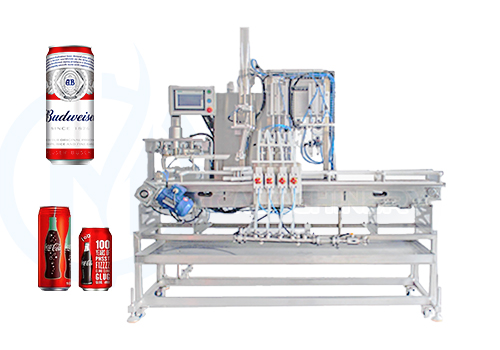

MIC Linear Beverage Canning Line (1000-1500CPH)

MIC Linear Beverage Canning Line

Machine is Suitable For:

The MIC Linear Beverage Canning Line is designed to meet the needs of beverage manufacturers that require high-efficiency and consistent quality in their canning processes. This system is ideal for a wide range of beverages, including carbonated drinks, fruit juices, energy drinks, iced teas, and more. Whether you're a small craft beverage producer or a large-scale manufacturer, this flexible beverage production line is well-suited to handle diverse beverage types and packaging needs. It offers an optimal solution for businesses looking to streamline production and meet growing market demands with precision and speed.

This beverage filling production line is capable of filling various sizes of cans, including standard sizes like 330ml, 500ml, and 1L, making it adaptable to different customer preferences and product specifications. The machine's ability to accommodate a range of beverage formulations ensures that it can handle both carbonated and non-carbonated drinks without compromising quality.

|

|

Machine |

|

Filling head The beer canning machine filling head ensures precise and consistent filling, using advanced technology to control beer volume and minimize waste. Designed for efficiency, it supports high-speed operations while maintaining product quality. |

|

|

|

Conveyor |

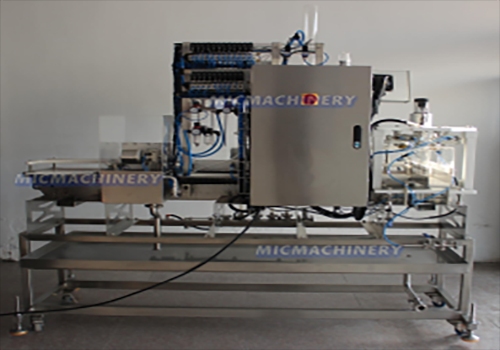

Working Principle:

The MIC Linear Beverage Canning Line operates with a fully automated system that streamlines the entire canning process, ensuring high output and minimal manual intervention. The line is designed to provide seamless integration across all stages of production, from cleaning and filling to sealing and labeling.

1)Cleaning and Sterilizing: The process begins with the cleaning and sterilization of cans, ensuring that every can is free from contaminants. This step is crucial for maintaining the hygiene and safety of the beverage, particularly for products with sensitive ingredients.

2)Filling: The beverage filling production line incorporates advanced filling technology that ensures accurate and consistent filling of cans. It is equipped with specialized filling valves that handle carbonated beverages efficiently, preventing foaming and ensuring that each can is filled to the exact required volume. This system is designed for both still and sparkling beverages, allowing for flexibility in the types of products it can process.

3)Sealing: After filling, the cans move to the sealing station, where they are securely sealed with a lid. The line is equipped with a high-performance capping system that provides precise and reliable sealing, preventing leaks and preserving the beverage's quality and freshness.

4)Capping and Labeling: The beverage canning line features an automated capping system that is compatible with various cap types, ensuring a secure seal every time. Additionally, the system includes labeling stations for easy application of branding and product information, contributing to efficient packaging.

5)Control System: The entire process is controlled through a PLC system, providing real-time monitoring and allowing for easy adjustments to the machine settings. This enhances the overall efficiency of the production line and minimizes the risk of human error.

Advantages:

1.High Efficiency and Speed: The MIC Linear Beverage Canning Line is designed to maximize production efficiency. The linear layout allows for a smooth flow of cans through each production stage, from cleaning and filling to sealing and labeling. This design reduces downtime and boosts throughput, making it ideal for manufacturers that need to meet high-volume production demands.

2.Precise Filling and Capping: The advanced filling technology ensures accurate and consistent filling, minimizing product waste. The system is designed to handle both carbonated and non-carbonated beverages without compromising on product quality, while the sealing system guarantees that cans are securely closed to prevent leaks or contamination.

3.Flexibility and Versatility: This beverage canning line is highly adaptable, capable of filling and packaging a wide range of beverage types and can sizes. The system can easily be adjusted to accommodate various production requirements, making it a versatile solution for manufacturers looking to expand their product range.

4.Compact and Space-Efficient Design: The linear configuration of the beverage production line is compact and space-efficient, allowing manufacturers to optimize their production area. Despite its small footprint, the system delivers high output, making it a great option for facilities with limited space.

5.Reduced Labor Costs: By automating the canning process, the beverage filling production line reduces the need for manual labor, helping companies to cut down on labor costs. This automation not only improves operational efficiency but also enhances the consistency and quality of the final product.

6.Low Maintenance and Durability: Built with high-quality materials, the MIC Linear Beverage Canning Line is designed for long-term performance. The robust construction ensures that the system can withstand the demands of continuous production, while its low-maintenance design reduces downtime and operational costs.

7.Advanced Control System: The PLC control system provides real-time monitoring and easy operation, allowing operators to manage the entire canning process from a central control panel. This enhances the accuracy and efficiency of the production line, while also allowing for quick troubleshooting and adjustments.

The MIC Linear Beverage Canning Line provides beverage manufacturers with a reliable, efficient, and scalable solution for their canning needs. With its high-speed operation, precise filling and capping, and user-friendly interface, this system ensures that manufacturers can deliver high-quality beverages while maintaining optimal production efficiency. Whether you're a craft brewery or a large-scale beverage producer, this system is built to support your business's growth and success.

|

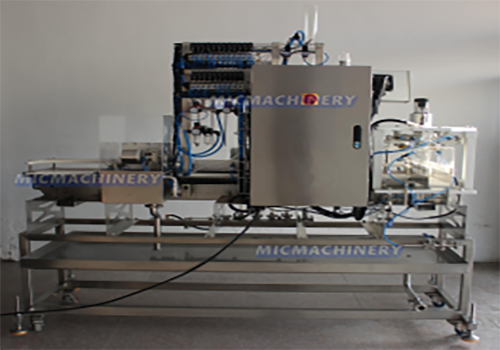

Equipment Parameter |

MIC 4-4-1 Beer Can Rinser Filler Seamer |

|

|

1 |

Dimension (L*W*H) |

2.00×0.91×1.85M |

|

2 |

Equipment Weight |

400KG |

|

3 |

Packing Size (L*W*H) |

2.20×1.15×2.05M |

|

4 |

Packing Weight |

550KG |

|

5 |

Production Capacity |

1200- 1500pcs/ H(330ml) 396-495L/ H 1000- 1200pcs/ H(500ml) 500-600L/ H |

|

6 |

Voltage |

380V-3 Phases-50Hz (Customized) |

|

7 |

Power port |

3P+ N+G |

|

8 |

Power consumption |

2.0-3.5KW |

|

9 |

Main Material |

SUS304 |

|

10 |

Beer Storage Tank Pressure |

0.15-0.2Mpa (22-30PSI) 1.5" Tir-clamp |

|

11 |

Compressed Air |

0.5-0.7Mpa (75.0- 105PSI) OD:Ф10mm |

|

12 |

Jacking Can Pressure |

0.20-0.30Mpa (30-45PSI) |

|

13 |

CO2 Pressure |

0.15-0.2Mpa (22-30PSI) OD:Ф10mm |

|

14 |

Flip- Rinse Pressure |

0.15-0.20Mpa(22-30PSI) 1.5" Tir-clamp |

|

15 |

Exit- Rinse Water Pressure |

0.15-0.20Mpa(22-30PSI) 1.5" Tir-clamp |