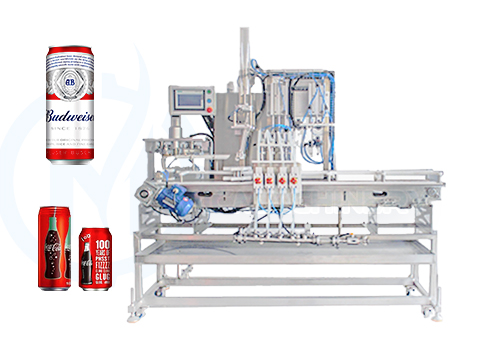

MIC Linear Beverage Filling Equipment (1000-1500CPH)

Machine is Suitable For

The MIC Linear Beverage Filling Equipment is an ideal solution for manufacturers looking to streamline their beverage production processes. This machine is designed to handle a wide range of beverages, including both carbonated and non-carbonated drinks, making it versatile enough to accommodate various product types. It is particularly well-suited for bottling beverages such as soft drinks, juices, teas, and flavored water.

This beverage filling equipment is perfect for medium- to large-scale production facilities, offering efficient, high-speed filling with precise volume control. Whether you're in the business of bottling large quantities of carbonated drinks or non-carbonated beverages, the MIC Linear Beverage Filling Equipment ensures a seamless production process that meets the demands of modern beverage manufacturing. It also integrates well with other beverage packaging equipment, offering a complete solution for beverage producers.

|

|

Machine |

|

Filling head The beer canning machine filling head ensures precise and consistent filling, using advanced technology to control beer volume and minimize waste. Designed for efficiency, it supports high-speed operations while maintaining product quality. |

|

|

|

Conveyor |

Working Principle of Beverage Filling Equipment

The MIC Linear Beverage Filling Equipment operates on a linear filling system that enables quick and accurate filling of beverage containers. The machine uses advanced filling valves that are equipped with sensors to maintain precise liquid levels and prevent spills, ensuring that every bottle is filled to the exact required volume.

In the case of carbonated beverages, the beverage filling equipment integrates a carbonation retention system that minimizes the risk of losing carbonation during the filling process. The filling process is quick and efficient, with the liquid dispensed into each container under controlled pressure to maintain product integrity.

The beverage filling machine manufacturers ensure that the machine is equipped with high-quality, durable materials to withstand the rigors of continuous production cycles. The equipment is fully automated, with a touch-screen control system that allows for easy operation and monitoring. Additionally, the machine features an automatic cleaning system, which is crucial for maintaining hygienic conditions and ensuring the safety and quality of each beverage.

Advantages of Beverage Filling Equipment

High-Speed Production: The linear design of the MIC Linear Beverage Filling Equipment ensures fast and efficient production, making it ideal for high-output beverage manufacturing. It can handle large volumes of beverages in a short amount of time, optimizing productivity.

1、Accurate and Consistent Filling

This beverage filling equipment offers precise and consistent filling, ensuring that each bottle receives the exact same amount of liquid, reducing waste and ensuring high-quality products every time.

2、Versatile Beverage Handling

The MIC Linear Beverage Filling Equipment can accommodate a variety of beverage types and container sizes, including PET and glass bottles. This flexibility makes it suitable for manufacturers that produce different beverage products or package sizes.

3、Integration with Beverage Packaging Equipment

This machine seamlessly integrates with other beverage packaging equipment, such as capping and labeling systems, to provide a fully automated production line for manufacturers. This integration ensures smooth operation across the entire packaging process, reducing bottlenecks and increasing production efficiency.

4、Cost-Effective Operation

The machine is designed for energy efficiency, which helps reduce operational costs. Its automated system also minimizes the need for manual intervention, reducing labor costs and improving the overall cost-effectiveness of the production process.

5、Durability and Reliability

Built with high-quality components and designed for continuous use, this beverage filling equipment is durable and reliable, ensuring long-term performance and minimal downtime.

6、Hygienic Design

The machine includes automatic cleaning and sanitizing functions to maintain the highest hygiene standards. This is especially important in the beverage industry, where cleanliness and sanitation are critical to product quality and consumer safety.

7、Easy Maintenance

The MIC Linear Beverage Filling Equipment is designed for easy maintenance and servicing, reducing downtime and ensuring that production continues smoothly with minimal interruptions.

8、Enhanced Automation

With its automated filling, capping, and cleaning functions, the machine requires minimal manual intervention, improving the efficiency of the production line while reducing human error.

In conclusion, the MIC Linear Beverage Filling Equipment is a robust and reliable solution for beverage manufacturers, offering high-speed, accurate filling with minimal waste. As one of the leading beverage filling machine manufacturers, Jiangsu Mic Machinery is committed to delivering advanced filling technology that meets the evolving needs of the beverage industry. With its energy efficiency, versatility, and precision, this machine provides a solid foundation for the successful operation of modern beverage production lines, integrating seamlessly with other beverage packaging equipment for a streamlined production process.

|

Equipment Parameter |

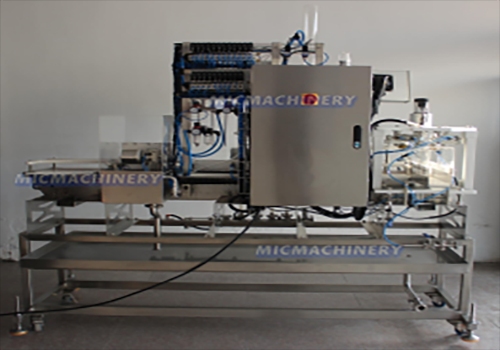

MIC 4-4-1 Beer Can Rinser Filler Seamer |

|

|

1 |

Dimension (L*W*H) |

2.00×0.91×1.85M |

|

2 |

Equipment Weight |

400KG |

|

3 |

Packing Size (L*W*H) |

2.20×1.15×2.05M |

|

4 |

Packing Weight |

550KG |

|

5 |

Production Capacity |

1200- 1500pcs/ H(330ml) 396-495L/ H 1000- 1200pcs/ H(500ml) 500-600L/ H |

|

6 |

Voltage |

380V-3 Phases-50Hz (Customized) |

|

7 |

Power port |

3P+ N+G |

|

8 |

Power consumption |

2.0-3.5KW |

|

9 |

Main Material |

SUS304 |

|

10 |

Beer Storage Tank Pressure |

0.15-0.2Mpa (22-30PSI) 1.5" Tir-clamp |

|

11 |

Compressed Air |

0.5-0.7Mpa (75.0- 105PSI) OD:Ф10mm |

|

12 |

Jacking Can Pressure |

0.20-0.30Mpa (30-45PSI) |

|

13 |

CO2 Pressure |

0.15-0.2Mpa (22-30PSI) OD:Ф10mm |

|

14 |

Flip- Rinse Pressure |

0.15-0.20Mpa(22-30PSI) 1.5" Tir-clamp |

|

15 |

Exit- Rinse Water Pressure |

0.15-0.20Mpa(22-30PSI) 1.5" Tir-clamp |