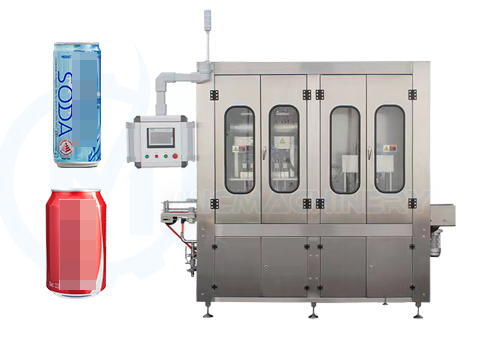

MIC 6-1 Linear Can Filling Sealing Machine

Introduction

This combination machine is suitable for the filling and sealing of easy-open cans in the beer and carbonated beverage industries. The entire machine structure integrates filling and sealing into one unit, with the filling system powered by the cap-sealing system via a synchronized gear drive, ensuring synchronous operation of both systems.

The filling valve uses internationally advanced electromagnetic flow meters and isobaric filling technology. The valve has an added CO2 replacement component during the filling process, effectively addressing the issue of oxygen control in traditional filling machines. The use of flow meters ensures filling accuracy within ±2ml. The sealing process uses double curling and spinning, which meets the sealing requirements of can and lid manufacturers both domestically and internationally. The entire machine is automated with frequency control, ensuring smooth filling, fast speeds, accurate filling volumes, no filling without cans, and no capping without cans. Automatic feed control makes it suitable for the filling and sealing of 250ml-500ml cans, and is the latest international equipment for craft beer canning.

Features

1. Compact size, easy to transport, and flexible installation.

2. The filling method is similar to rotary machines, utilizing an isobaric-replacement-filling-depressurizing mode. Each parameter can be set to effectively control oxygen levels during the filling process.

3. All food-contact surfaces are made of food-grade materials to ensure food safety.

4. Key components are imported, such as bearings, seals, and sensors.

5. Filling accuracy is controlled by flow meters, ensuring high precision. The filling amount for each valve can be adjusted on the touch screen, making it convenient and precise.

6. Before sealing, air is blown into the top of the cans similar to high-speed sealing machines, ensuring proper oxygen control while sealing.

7. Sealing parameters can be set on the touch screen, with flexible micro-adjustments to the sealing structure, making the machine easy to adjust and operate.

8. The machine is equipped with a CIP (Clean-in-Place) system for reverse circulation cleaning. The filling tank features two 360° rotating cleaning balls to ensure thorough cleaning of the filling valves, gas displacement pipes, and feed lines when the equipment switches to CIP cleaning mode, guaranteeing clean equipment after production.

9. The machine can quickly and easily switch between different can types (330ml, 500ml, etc.) without requiring part replacements.

Manufacturing Standards

1. The frame of the combination machine is made from USU304 stainless steel.

2. The filling valve and contact parts with materials are made from USU304 stainless steel.

3. The sealing rollers are made of high-strength materials.

4. The drive system is connected to the sealing machine.

5. The control box uses a mini-type cabinet with a touch screen.

6. The control system uses imported electrical components, such as Schneider, Siemens, and Balluff.

7. The pneumatic system uses Japanese SMC components.

8. The gearbox is from Taiwan Taibang.

9. The feed proportion valve is from Germany Gemi.

10. CE standard design.

| Production Speed | 25CPM/330ml, 20CPM/500ml, 2-piece cans |

| Applicable Can Type | 211 (330ml/500ml) |

| Applicable Cap Type | 202 |

| Filling Heads | 6 |

| Seaming Heads | 1 |

| Filling Valve Structure | Electronic valve |

| Inlet/Outlet Conveyor Height | Inlet: 830mm±50mm, Outlet: 900mm±50mm |

| Mechanical Standards | ISO metric bolts, nuts, and food-grade materials |

| Seaming Device | Oil-free |

| Can Direction | 180° linear |

| Cap Feeding Method | Manual cap placement with simple feeder slot |

| Electrical Control | Accurate filling volume control |

| Fault point alert on human-machine interface | |

| Cap absence detection | |

| Daily/Shift production counter | |

| Circulating CIP cleaning system | |

| Dissolved Oxygen Control | Oxygen increase: ≤20PPB during filling |

| Filling Accuracy | ±2mm |

| Total Power | 1.0KW |

| Voltage | 2-phase 4-wire, 3-phase 220V, 50HZ |

| Weight | 500KG |

| Installation | Flexible mobility, can be fixed after movement |