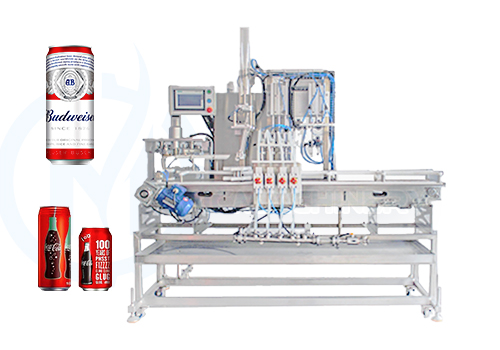

MIC Linear Soft Drink Canning Machine (1000-1500CPH)

Company Introduction

Jiangsu Mic Machinery is a leading manufacturer of advanced beverage processing and packaging equipment. With years of expertise in the industry, we specialize in developing innovative solutions that meet the needs of modern beverage manufacturers. Our commitment to quality and precision has earned us a global reputation for excellence. The MIC Linear soft drink canning machine is one of our flagship products, designed to help beverage manufacturers achieve efficient and reliable production while maintaining the highest standards of product quality.

|

|

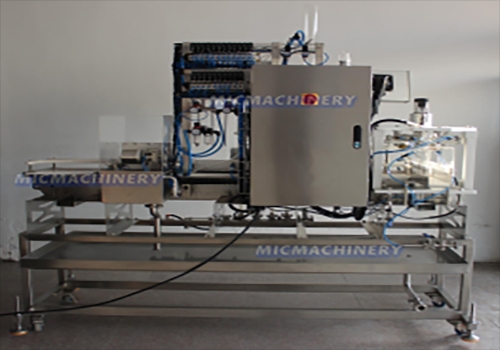

Machine |

|

Filling head The beer canning machine filling head ensures precise and consistent filling, using advanced technology to control beer volume and minimize waste. Designed for efficiency, it supports high-speed operations while maintaining product quality. |

|

|

|

Conveyor |

Working Principle of Soft Drink Canning Machine

The MIC Linear soft drink canning machine operates using a sophisticated linear filling process to ensure precision and efficiency. The working process includes:

Can Feeding: Empty cans are automatically fed into the system through a conveyor.

Rinsing Process: The cans are rinsed using a high-pressure water system to ensure they are clean and ready for filling.

Filling System: Using advanced counter-pressure filling technology, the can filling machine for soft drinks fills each can with the exact volume of liquid. This method preserves carbonation, ensuring that the fizzy beverages retain their freshness and quality.

Sealing Process: After filling, the cans are hermetically sealed using high-quality sealing components, ensuring no leakage and extended shelf life.

Discharge: The sealed cans are discharged onto an output conveyor, ready for further packaging or distribution.

This streamlined process minimizes wastage and ensures a smooth production line, making the MIC Linear soft drink tin can filling machine a reliable choice for beverage manufacturers.

Advantages of Soft Drink Canning Machine

The MIC Linear soft drink canning machine offers a range of advantages that make it stand out in the industry:

1、High Efficiency

With its linear design, the machine provides fast and accurate filling, significantly improving production rates.

2、Versatility

The system is compatible with various can sizes and shapes, making it suitable for a wide range of products, from soft drinks to sparkling water.

3、Preservation of Carbonation

The counter-pressure filling system ensures that carbonation levels remain intact, delivering a consistently fizzy and fresh beverage.

4、User-Friendly Operation

Equipped with an intuitive control panel, operators can easily monitor and adjust machine settings for optimal performance.

5、Durable Construction

Built with high-quality stainless steel and food-grade materials, the soft drink tin can filling machine ensures durability and compliance with hygiene standards.

6、Customizable Features

Jiangsu Mic Machinery offers customization options to tailor the machine to specific production requirements.

7、Energy Efficiency

Designed with energy-saving components, the system reduces operational costs while maintaining top-notch performance.

8、Low Maintenance

The robust design of the MIC Linear can filling machine for soft drinks ensures long-term reliability and minimizes maintenance needs, reducing downtime for manufacturers.

At Jiangsu Mic Machinery, we understand the importance of high-performance equipment in the beverage industry. The MIC Linear soft drink canning machine combines innovation, efficiency, and reliability, making it the ideal solution for manufacturers looking to enhance their production processes.

|

Equipment Parameter |

MIC 4-4-1 Beer Can Rinser Filler Seamer |

|

|

1 |

Dimension (L*W*H) |

2.00×0.91×1.85M |

|

2 |

Equipment Weight |

400KG |

|

3 |

Packing Size (L*W*H) |

2.20×1.15×2.05M |

|

4 |

Packing Weight |

550KG |

|

5 |

Production Capacity |

1200- 1500pcs/ H(330ml) 396-495L/ H 1000- 1200pcs/ H(500ml) 500-600L/ H |

|

6 |

Voltage |

380V-3 Phases-50Hz (Customized) |

|

7 |

Power port |

3P+ N+G |

|

8 |

Power consumption |

2.0-3.5KW |

|

9 |

Main Material |

SUS304 |

|

10 |

Beer Storage Tank Pressure |

0.15-0.2Mpa (22-30PSI) 1.5" Tir-clamp |

|

11 |

Compressed Air |

0.5-0.7Mpa (75.0- 105PSI) OD:Ф10mm |

|

12 |

Jacking Can Pressure |

0.20-0.30Mpa (30-45PSI) |

|

13 |

CO2 Pressure |

0.15-0.2Mpa (22-30PSI) OD:Ф10mm |

|

14 |

Flip- Rinse Pressure |

0.15-0.20Mpa(22-30PSI) 1.5" Tir-clamp |

|

15 |

Exit- Rinse Water Pressure |

0.15-0.20Mpa(22-30PSI) 1.5" Tir-clamp |