Liquid Level Detector

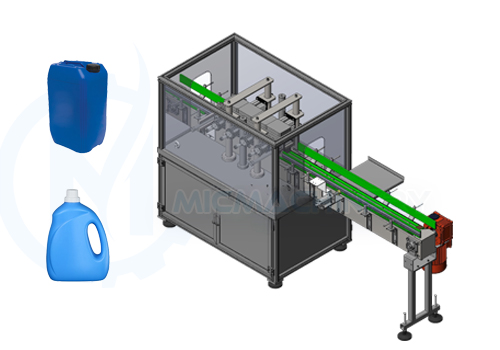

Liquid Level Detector is a level detection instrument developed and produced by our company, reaching advanced domestic and international standards. Utilizing low-energy photon sources and the interaction between the detected material and the photon, the ray intensity changes with the material's position, allowing control of the filling liquid material's capacity. Due to its non-contact measurement method, it fundamentally solves the problem of measuring the liquid capacity in filling lines, which is difficult for conventional weighing methods. Therefore, it is widely applied in the automatic online control of filling liquid materials in production lines for food, pharmaceuticals, chemicals, etc. (whether bottled or canned).

Design Basis

In the beverage packaging process, due to the stability of production equipment and the skill level of operators, each packaging step on the production line may have different packaging quality defects. These defects lead to various defective products, affecting product quality. Specific issues include:

| Serial Number | Quality Defect | Risk | Description |

| 1 | High liquid level | Affects product quality, consumer complaints | Filling machine issue |

| 2 | Low liquid level |

Currently, most production enterprises use manual inspection or weighing to control the above risks, but manual inspection or weighing has significant limitations, as shown below:

| Serial Number | Limitations | Description |

| 1 | Easily fatigued, leading to unstable accuracy | Highly affected by line speed |

| 2 | Low accuracy, large uncertainty in manual inspection | |

| 3 | Gradually increasing labor costs | |

| 4 | Weighing is inaccurate |

As seen above, using traditional manual inspection or weighing methods for various quality defects in the production line cannot achieve ideal detection results or effectively control production risks.

Solution

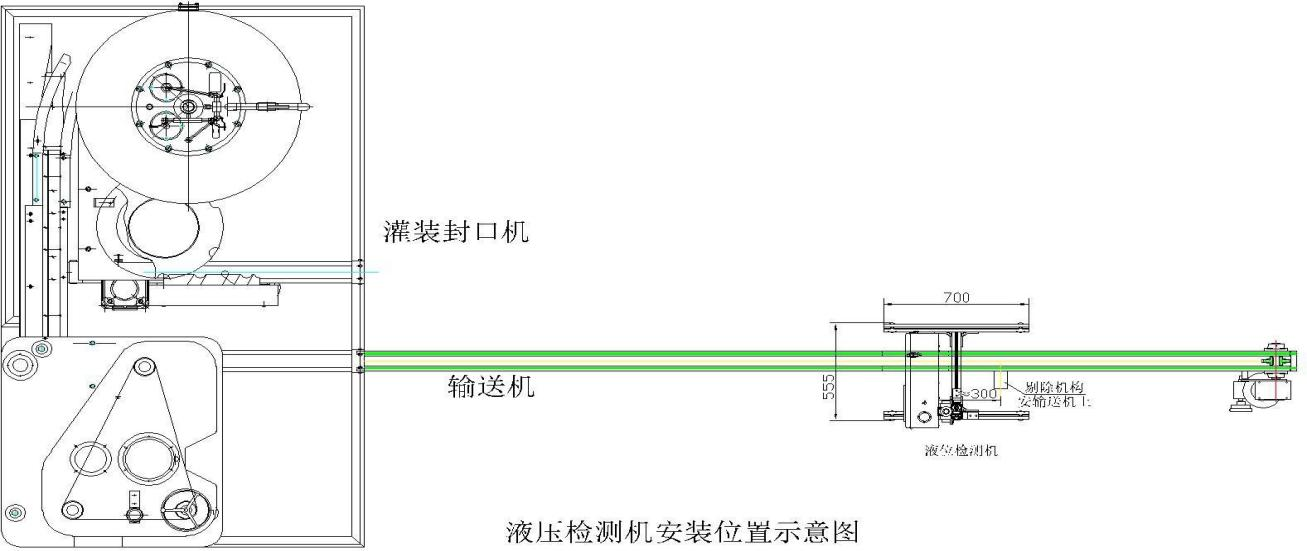

Based on the beverage production process for cans, the solution is to install automatic detection equipment at appropriate positions on the production line, enabling automatic online detection of each product and automatic rejection of defective items. The equipment installed is as follows:

| Serial Number | Installation Location | Installed Equipment |

| 1 | After filling and sealing | Radiation liquid level detector |

By installing automated detection equipment, quality control is realized across each packaging step, with defects being removed in real-time. In case of production faults, a complete alarm system promptly notifies on-site personnel to handle the issue, ensuring production efficiency.

Advantages of Installing Online Detectors

| Serial Number | Advantage | Description |

| 1 | High-speed, high-efficiency | Effectively replaces manual labor in high-speed production lines |

| 2 | High accuracy | Resolves issues with low accuracy in manual checks |

| 3 | Reliability guarantee | The equipment runs more reliably than manual inspection |

| 4 | Production data management | Collects and analyzes production data, calculates product defect rates |

| 5 | Packaging line information management | Information management for post-packaging processes |

These advantages are not only beneficial for the detection itself but also highlight the importance of advanced automated equipment in future smart factories. For example, providing industrial Ethernet interfaces for upper-level systems and offering various communication support for other devices, enabling future automation and networking upgrades.

Detection Content

• Liquid Level: Detects whether the filling liquid level is within the required standard.

• Applicable Occasions: Two-piece cans, three-piece cans, PET bottles, glass bottles, etc.

Technical Features

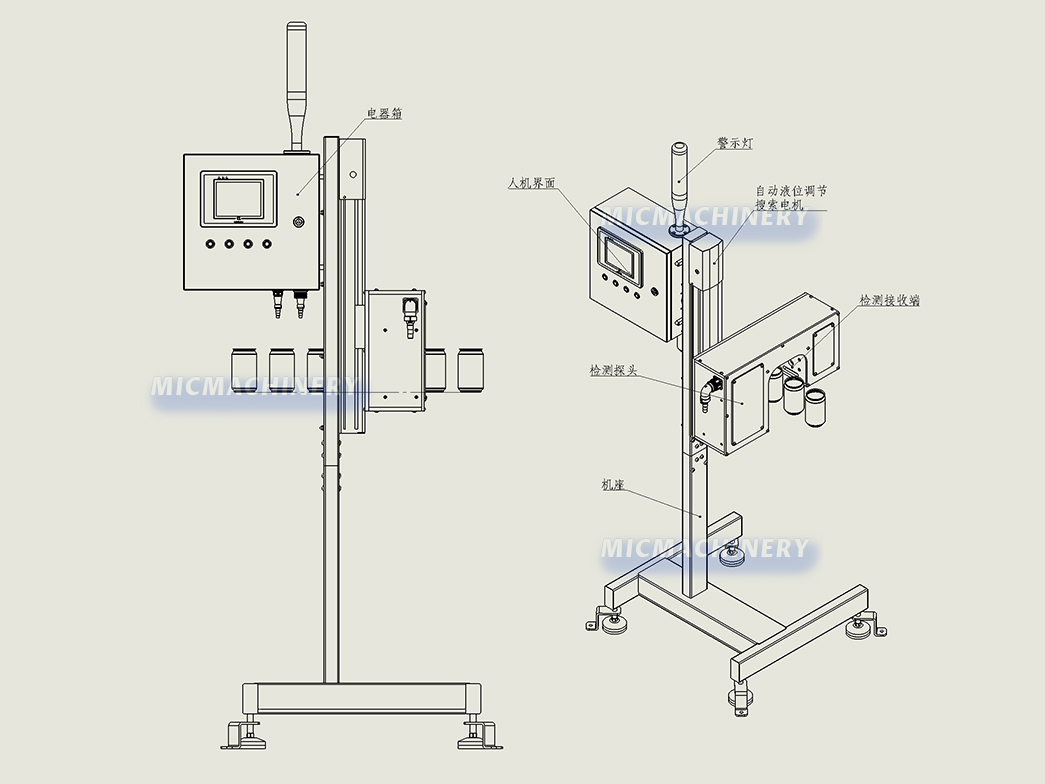

1. Non-contact detection, fast speed, high accuracy.

2. Automatically adapts to different production line speeds, dynamically performing detection.

3. Stainless steel outer casing, main unit sealed design, fog-proof, water-resistant, strong environmental adaptability.

4. Automatically blocks high-frequency ray emission when idle.

5. Hardware-based circuit, embedded operating system, ensures long-term stable operation.

6. Audible and visual alarms, automatically rejects defective containers.

7. 7-inch touchscreen for easy and reliable human-machine interface, flexible bottle type changes.

8. Large-screen Chinese display with LED backlight LCD, clear and bright, human-machine interaction operation.

9. No isotopic radioactive sources, soft ray design, safe and reliable radiation protection.

Liquid Level Detection Accuracy

| Detection Item | Liquid Level Value | Rejection Rate | Mis-rejection Rate |

| High liquid level | +1mm | ≥99.9% | ≤0.3% |

| Low liquid level | -1mm | ≥99.9% |

| Item | Specification |

| Conveyor Belt Line Speed | ≤ 8m/s (Maximum detection speed for 50mm can diameter is 800 cans/min) |

| Container Diameter |

20mm–100mm (Device selection varies based on container material density and diameter) |

| Dynamic Container Resolution | ±2mm (Foam and shaking may affect detection accuracy) |

| Static Liquid Level Measurement Accuracy | ≤ 5mm (water) |

| 8-Hour Static Measurement Stability | 0.15mm (water) |

| Reject Rate for Defective Containers | ≥ 99% (at detection speed of 1200 units/min) |

| Temperature Error | ≤ 25mm relative to 20°C, within the range of 0°C–40°C |

| Operational Requirements |

Minimum time width for "can" and "no can" detection is 10ms Conveyor belt must be stable (stability affects accuracy) |

| Name | Quantity | Remarks |

| X-ray vacuum tube | 1 piece | |

| X-ray receiver tube | 1 piece | |

| X-ray high-voltage power supply | 1 unit | |

| Siemens controller | 1 set | Siemens PLC, touch screen, analog module, etc. |

| Omron sensor | 1 set | |

| Ejector solenoid valve | 1 piece | |

| Ejector cylinder | 1 unit | |

| Switching power supply | 2 units | |

| Alarm system | 1 set | |

| Laser aligner | 1 set |