MIC Manual Beverage Canning Line (8CPM)

MIC Manual Beverage Canning Line

Machine is Suitable For:

The MIC Manual Beverage Canning Line is designed for small to medium-scale beverage production companies that require a flexible and cost-effective solution for canning their beverages. This machine is ideal for a wide variety of drinks, including carbonated beverages, juices, teas, and energy drinks. It is particularly suitable for producers who need a more hands-on approach to their canning process while still benefiting from the efficiency of automated systems for certain stages.

This beverage canning line is perfect for businesses just entering the beverage industry, craft beverage producers, or companies that have lower production demands but still wish to ensure high-quality packaging. Whether you are producing small batches or customized flavors, this system offers the adaptability required for diverse product lines.

|

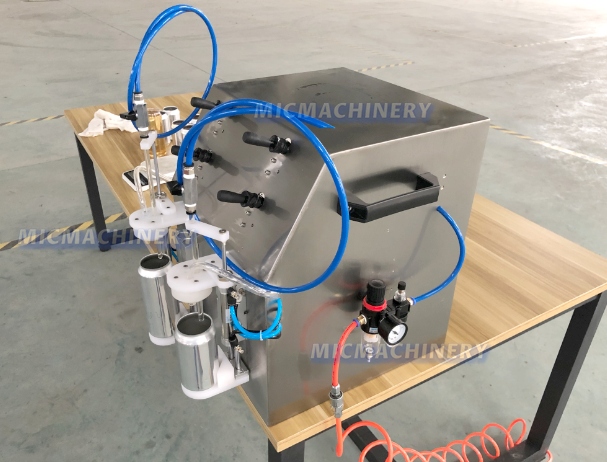

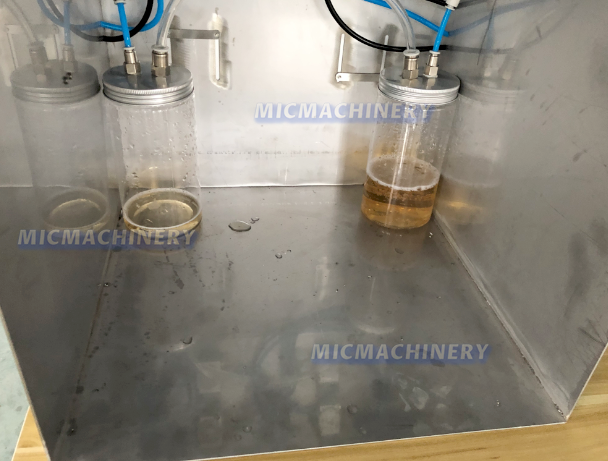

Filling Head The filling head of our beer canning machine ensures precise and consistent filling. It features advanced technology for accurate volume control, minimizing waste while maintaining high-quality standards in every can.

|

|

Control Button |

|

|

Material Barrel The material barrel of our beer canning machine is designed for durability and efficient beer storage. Made from high-quality, corrosion-resistant materials, it ensures safe, hygienic handling and easy access during the filling process. |

Machine Features:

The MIC Manual Beverage Canning Line offers a combination of manual operation and automated processes, delivering excellent performance in terms of productivity, flexibility, and cost-efficiency. Key features include:

Manual Loading and Unloading: The line requires operators to load and unload cans manually, making it ideal for smaller-scale production. However, this design does not sacrifice the precision and consistency that the beverage filling production line offers.

Filling System: This line includes a reliable filling system that ensures accurate and efficient beverage filling. It can handle various beverage types such as carbonated drinks, juices, and flavored water. The filling machine ensures that each can is filled to the desired volume, minimizing waste and improving product quality.

Capping Mechanism: The capping station is manual, giving operators control over the capping process. This system ensures that each can is sealed securely to maintain freshness and prevent leakage. The capping mechanism is compatible with various cap types, offering flexibility for different beverage packaging needs.

Canning Capacity: The beverage filling line is designed for lower-volume production runs. With a manual system in place, businesses can produce anywhere from small batches to larger runs depending on their needs. This flexibility makes it an attractive option for businesses with fluctuating production demands.

User-Friendly Interface: While the line requires manual input for loading and unloading, it is designed with simplicity in mind. Operators can quickly familiarize themselves with the equipment, making training and operational adjustments more efficient.

Durable Construction: The beverage canning line is built from high-quality materials that ensure long-term durability and reliability. With minimal maintenance requirements, this line can handle high-volume production with consistent results.

Versatile Canning: This line is capable of canning various container sizes, allowing businesses to cater to different market needs. Whether you are bottling 250ml cans or 500ml cans, the system offers versatility and easy adjustment between sizes.

Machine Introduction:

The MIC Manual Beverage Canning Line is an excellent choice for businesses looking to scale their canning processes without committing to high capital costs. By combining manual input with automation, this system offers the best of both worlds — cost efficiency, precision, and flexibility. The beverage filling production line within the system provides seamless filling, while the manual capping and unloading processes ensure that businesses maintain a hands-on approach that suits their production demands.

The line is designed to meet the growing demand for beverage packaging in both small-scale and boutique industries. It provides a simple yet effective solution for those seeking to package carbonated beverages, fruit juices, soft drinks, or other liquid products in cans.

The beverage filling line is designed to integrate easily into smaller production facilities. The simple setup process and easy-to-operate interface make it perfect for businesses that require a straightforward canning solution. Furthermore, the manual operation allows businesses to exercise more control over their production line, making it ideal for craft beverages or companies that want to experiment with different formulations and flavors.

Conclusion:

The MIC Manual Beverage Canning Line provides an ideal solution for small to medium-sized producers who need a reliable, flexible, and cost-effective way to can their beverages. It allows businesses to efficiently fill and seal cans while maintaining a high level of product quality. With the ability to handle different container sizes and beverage types, this machine is versatile and customizable to meet your specific needs. If you are looking for a beverage canning line that balances manual operation with automation, this system offers a smart solution for your production goals.

| Filling Heads | 2 Pieces |

| Production Capacity |

8 Cans per minute based on 330 ml and 550 ml |

| Filling Pressure | 0.4-0.6Mpa |

| Can Diameter Range | Ф40-90MM |

| Can Height | 92-168MM |

| Dimension | 575*550*480MM |

| Weight | 15KG |

| Name | Brand |

| Buttons | Schneider (France) |

| Touch screen | Siemens (Optional) |

| AC Contactor | Schneider (France) |

| PLC | Mitsubishi (Japan) / Siemens (Optional) |

| Frequency changer | Schneider (France) |

| Air cylinder | AirTAC (China) / FESTO (Optional) |

| Solenoid valve | AirTAC (China) / FESTO (Optional) |

| Relay | Autonics (Korea) / Omron (Optional) |

| Proximity switch | Autonics / Omron (Optional) |