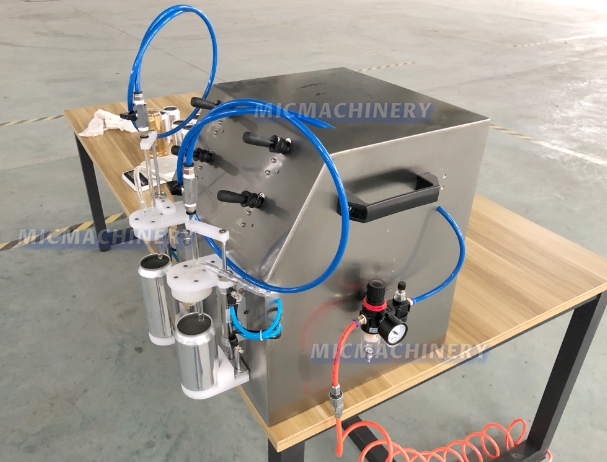

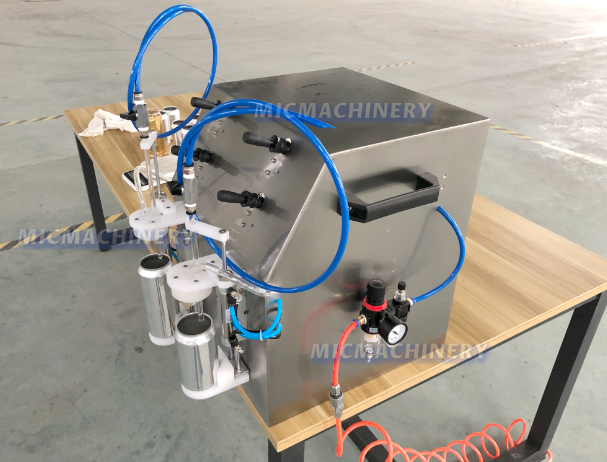

MIC Manual Soft Drink Filling Machine (8CPM)

Company Introduction

Jiangsu Mic Machinery is a renowned manufacturer specializing in high-quality beverage filling and packaging solutions. With a commitment to innovation and precision, we provide state-of-the-art equipment designed to meet the diverse needs of beverage manufacturers. Our extensive product line includes advanced solutions like the MIC Manual soft drink filling machine, which offers exceptional efficiency and reliability. Trusted by clients worldwide, we strive to deliver machinery that enhances productivity while maintaining the highest quality standards.

|

|

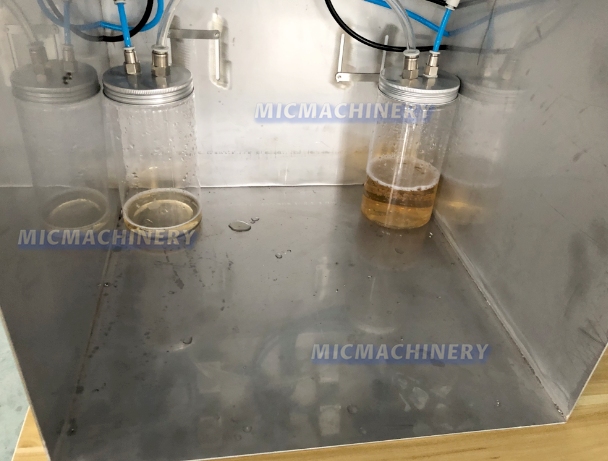

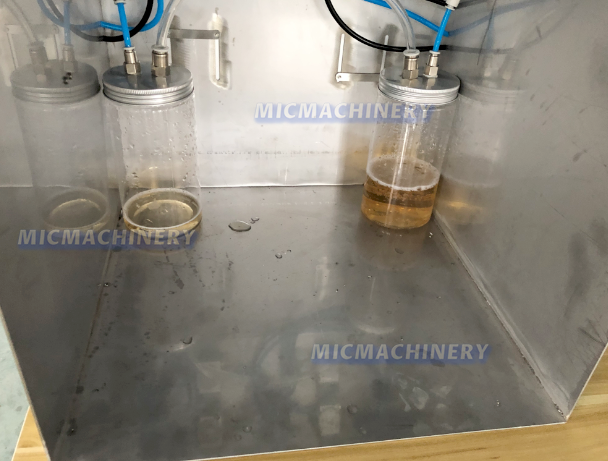

Filling Head The filling head of our beer canning machine ensures precise and consistent filling. It features advanced technology for accurate volume control, minimizing waste while maintaining high-quality standards in every can. |

|

Control Button |

|

|

|

Material Barrel The material barrel of our beer canning machine is designed for durability and efficient beer storage. Made from high-quality, corrosion-resistant materials, it ensures safe, hygienic handling and easy access during the filling process. |

Features of Soft Drink Filling Machine

The MIC Manual soft drink filling machine is designed to offer precise and efficient filling for a variety of carbonated beverages. Its user-friendly design and reliable performance make it ideal for small-scale and specialty beverage producers. Key features include:

Manual Operation with Precision:Operators can control the filling process manually, ensuring accuracy for each bottle. The system is easy to handle, making it suitable for small production volumes.

Compatibility with Carbonated Beverages:This carbonated soft drink filling machine is engineered to handle soda, sparkling water, and other fizzy beverages without compromising carbonation quality.

Robust Construction:Built with durable, food-grade stainless steel, the machine ensures hygiene and longevity, even in demanding production environments.

Flexible Bottle Compatibility:The MIC Manual soft drink packaging machine accommodates various bottle sizes and materials, such as PET and glass, providing versatility for manufacturers.

Compact Design:Its space-saving design makes it a great choice for businesses with limited operational areas, offering efficiency without taking up excessive space.

Hygienic Filling Process:The machine is designed for easy cleaning and maintenance, meeting food safety standards and minimizing the risk of contamination.

Advantages of Soft Drink Filling Machine

1、Cost-Effective Solution

The MIC Manual soft drink filling machine offers a budget-friendly alternative for small to medium-scale manufacturers, reducing operational costs without compromising quality.

2、Preserves Carbonation Levels

The system is designed to maintain the carbonation integrity of beverages, ensuring a consistent and refreshing product for consumers.

3、Ease of Use

Its straightforward operation makes it ideal for operators with minimal training, enabling smooth production processes.

4、Versatility Across Beverage Types

This soft drink packaging machine can handle a wide range of carbonated beverages, making it suitable for diverse production needs.

5、Durable and Reliable

Constructed with high-quality materials, the machine ensures durability and dependable performance, minimizing downtime and repair costs.

6、Portable and Compact

The lightweight and compact design allow the machine to be easily moved and installed, providing flexibility in production setup.

7、Scalable for Growing Businesses

The MIC Manual carbonated soft drink filling machine is perfect for startups or smaller operations, with the potential to integrate into larger systems as production scales.

At Jiangsu Mic Machinery, we are dedicated to providing professional and reliable solutions tailored to our clients' needs. The MIC Manual soft drink filling machine exemplifies our commitment to quality and innovation, offering exceptional performance for carbonated beverage manufacturers. For more information or to explore how this machine can enhance your production line, contact us today!

| Filling Heads | 2 Pieces |

| Production Capacity |

8 Cans per minute based on 330 ml and 550 ml |

| Filling Pressure | 0.4-0.6Mpa |

| Can Diameter Range | Ф40-90MM |

| Can Height | 92-168MM |

| Dimension | 575*550*480MM |

| Weight | 15KG |

| Name | Brand |

| Buttons | Schneider (France) |

| Touch screen | Siemens (Optional) |

| AC Contactor | Schneider (France) |

| PLC | Mitsubishi (Japan) / Siemens (Optional) |

| Frequency changer | Schneider (France) |

| Air cylinder | AirTAC (China) / FESTO (Optional) |

| Solenoid valve | AirTAC (China) / FESTO (Optional) |

| Relay | Autonics (Korea) / Omron (Optional) |

| Proximity switch | Autonics / Omron (Optional) |