Mechanical Vapor Recompression

Mechanical Vapor Recompression – Energy-Saving Evaporation System

Mechanical vapor recompression is an advanced energy-saving evaporation technology that reuses secondary steam. By compressing this vapor into higher pressure, it provides the heating energy needed for continuous operation. This reduces steam consumption, lowers production costs, and increases overall efficiency, making it a vital solution in modern industries.

Mechanical Vapor Recompression System Technology Principle

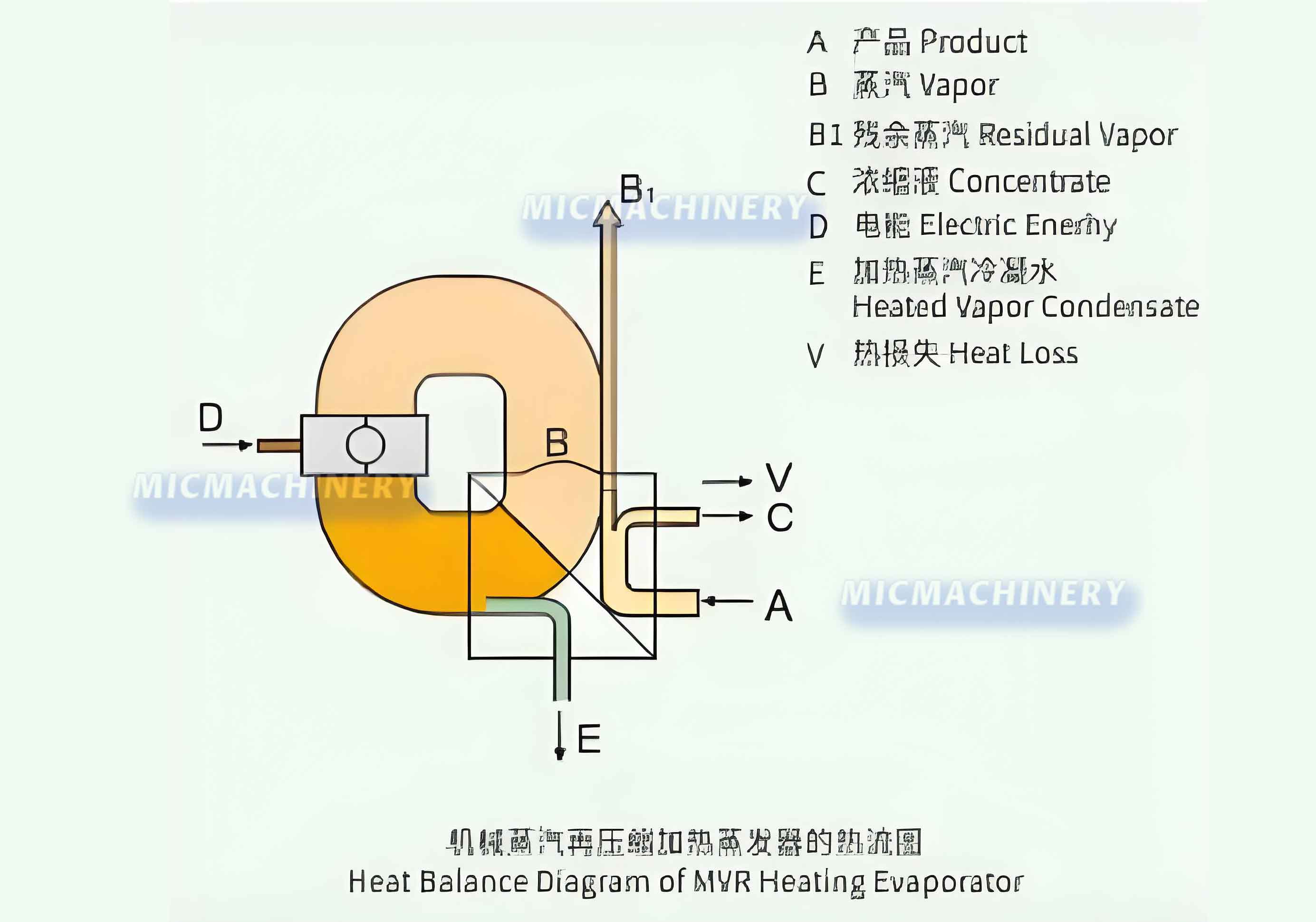

When mechanical vapor is recompressed, the mechanically driven compressor compresses the secondary vapor generated by the evaporator to form a higher pressure. In this sense, the compressor acts as a heat pump to increase the energy of the vapor. In other words, in this process, the low-temperature vapor is compressed by the compressor to improve its temperature and pressure, increase its enthalpy, and then flow into the heat exchanger for heat exchange and condensation, thus making use of the latent heat of the secondary vapor. Except during machine startup, no generation of additional vapor is required during the entire evaporation process.

The Reason to Use MVR

• Low energy consumption per unit

• Gentle evaporation due to low temperature

• Short retention time due to the frequently used single effect

• Simple process and high practicability

• Excellent service performance at some loads

• Low operating costs

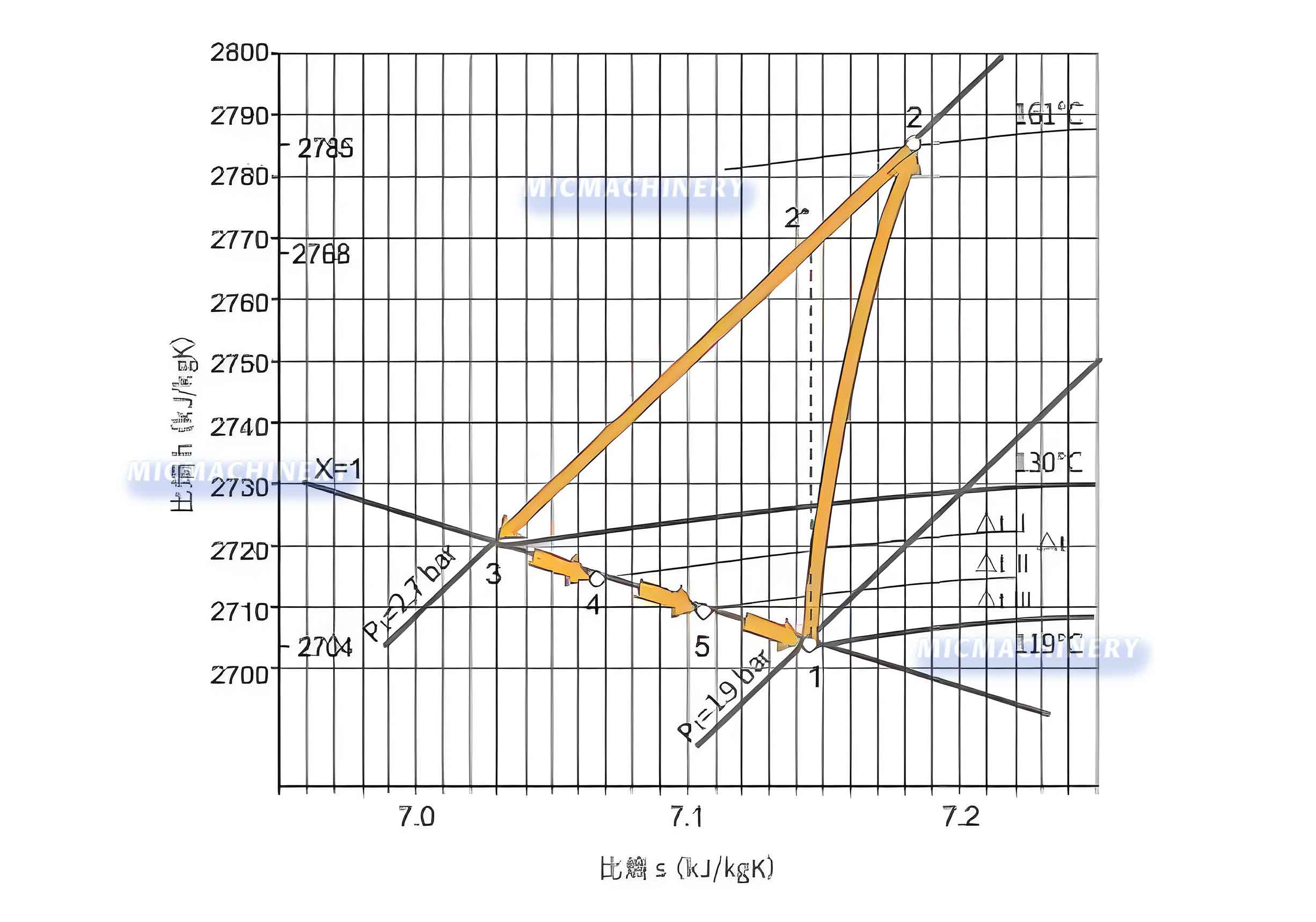

MVR Mechanical Vapor Recompression Heat Balance Diagram

Technical Characteristics

1. Low energy consumption and low operating costs

2. Small space occupation

3. Requires fewer public utilities and less total investment

4. Stable operation with a high degree of automation

5. Requires no primary steam

6. Short retention time due to the frequently used single effect

7. Simple process, high practicability, and excellent service performance at some loads

8. Low operating costs

9. Capable of evaporating at and below 40 °C without any refrigerating plant, making it particularly suitable for heat-sensitive materials

Design and Functions

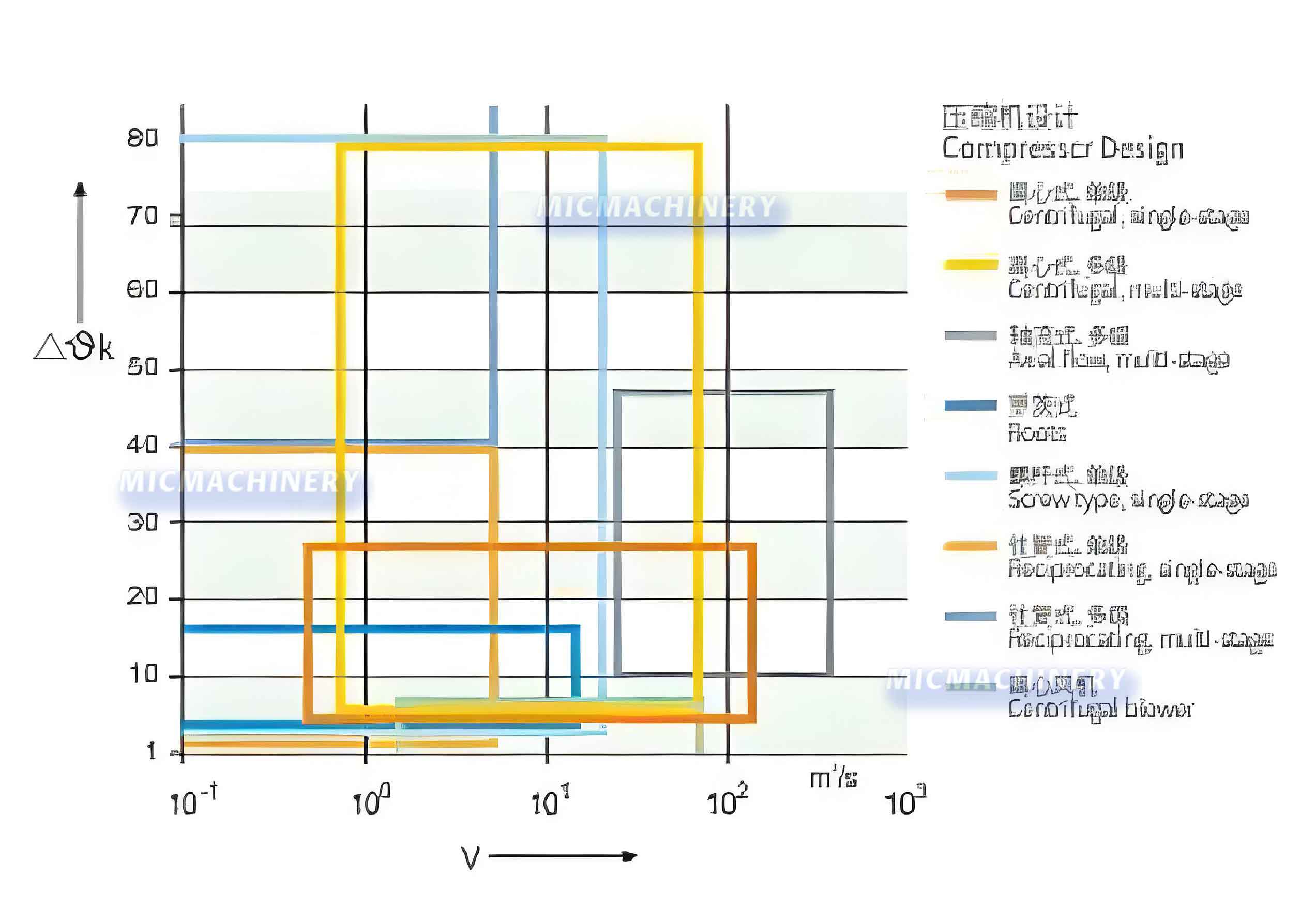

Vapor compressors currently used for MVR technology have two main forms: the positive displacement type and the centrifugal type (i.e., speed type).

Among positive displacement compressors, the most commonly used is the Roots compressor, which compresses gas by bringing two (or three) lobed rotors into relative motion within the cylinder. This type of compressor keeps the two rotors engaged with each other by means of synchromesh gears located at the ends of the rotor shafts. The curved surface of each concave section on the rotor, together with the inner wall of the cylinder, forms a working displacement, which carries gas away from the suction port during rotor rotation. When the carried gas reaches the vicinity of the exhaust port, the pressure in the working displacement abruptly increases as it connects with the exhaust port due to the return of gas at higher pressure. The gas is then delivered into the exhaust passage. This compressor is characterized by a large pressure ratio but a small suction rate.

Centrifugal compressors provide energy to the gas by means of the high-speed rotation of impeller blades. In these compressors, the gas is accelerated and then passes through the diffuser located downstream of the impeller, where it decelerates. In this process, the kinetic energy of the gas is transformed into pressure energy. According to the direction of fluid flow through the impeller, these compressors are classified as axial flow, mixed flow, or centrifugal compressors. They are renowned for their large pressure ratio, high flow rate, and good stability.

The choice of the most suitable compressor depends on the specific operating conditions and the overall system economy. Critical parameters include the required pressure rise and the volume flow of steam to be compressed.

Functional Range of the Compressor Used for Vapor Recompression

According to the manufacturer’s data, the functional range of the compressor used for steam recompression corresponds to the rise in water vapor condensation temperature (ΔT, K) at an initial state of 1 bar and 100 °C.

The MVR operating principle is illustrated in the Enthalpy–Entropy Diagram as shown on the left. Being compressed by the compressor, the vapor changes from the saturated state 1 to state 2 after its temperature and pressure rise. It then enters the evaporator to heat the materials, releasing latent heat and cooling down until it returns to the pressure condition of state 1.