Minute Vertical CIP System

Minute Vertical CIP System – Efficient Industrial Cleaning

A CIP system (Clean-in-Place system) is essential for modern industrial facilities that require hygienic cleaning of tanks, pipelines, and process equipment without disassembly. The minute vertical CIP system provides automated, efficient cleaning, minimizing downtime and ensuring compliance with strict hygiene standards. This CIP cleaning system is ideal for industries such as dairy, beverage, pharmaceutical, and food processing.

Overview

Applications

The minute vertical CIP system allows automated cleaning of tanks, vessels, pipelines, and processing equipment while maintaining high sanitation standards. It performs complete cleaning cycles, including rinsing, detergent washing, and sanitizing, without requiring manual intervention. By integrating advanced control systems, this CIP clean in place system ensures consistent cleaning performance, reducing the risk of contamination and improving operational efficiency.

This CIP tank cleaning system is especially suitable for vertical tanks or vessels where space is limited, making it ideal for small-to-medium scale production lines. The system also helps prevent cross-contamination of active ingredients, removes insoluble foreign particles, and reduces or eliminates microbial contamination and heat-related risks to the product.

Technical Principle

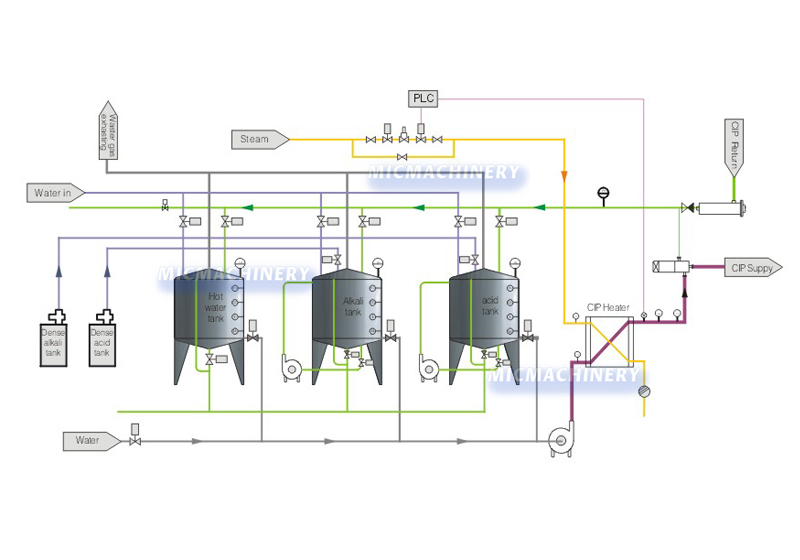

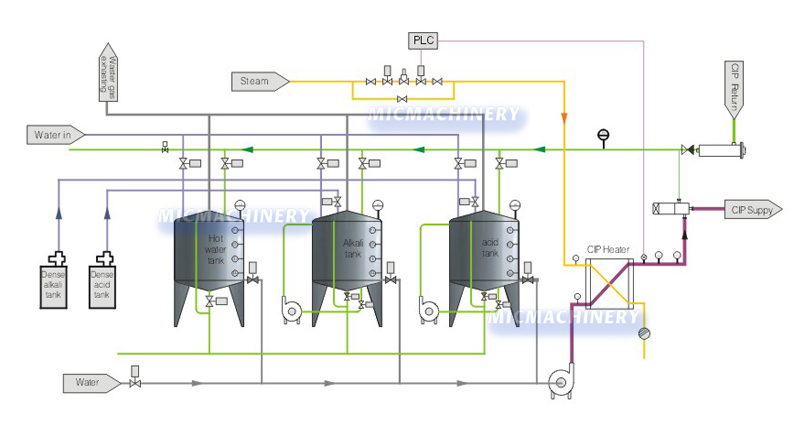

The CIP washing system operates based on controlled fluid circulation, temperature management, and chemical dosing. Cleaning liquids circulate through tanks, nozzles, and pipelines at predefined flow rates and temperatures, effectively removing residues and biofilms. The vertical design ensures cleaning fluids are applied from top to bottom, achieving complete coverage of tank interiors.

Advanced models include programmable logic controllers (PLC) for automated timing, flow, and chemical dosage control, allowing precise and repeatable cleaning cycles. Multiple cleaning sequences can be programmed, including pre-rinse, caustic wash, acid wash, and final rinse, tailored to specific process requirements.

Machine Configuration

The minute vertical CIP system includes key components to ensure effective operation:

• CIP tank – the primary vessel for cleaning and chemical circulation

• Pumps – circulate cleaning liquids through tanks, pipelines, and process equipment

• Heat exchangers – maintain optimal cleaning temperatures and conserve energy

• Valves and nozzles – control flow patterns and ensure uniform cleaning coverage

• PLC control system – automates cycles, dosing, and flow, ensuring consistent results

These components work together to guarantee thorough cleaning, precise control, and safe operation throughout every cycle.

Performance Features

• Flexible and Versatile

• The system can perform individual operations such as acid washing, alkali washing, and hot water rinsing, or it can be programmed for fully automatic

• cleaning according to specific requirements. It not only effectively cleans equipment but also controls microbial growth. Semi-automatic and fully automatic

• control systems can be configured based on customer needs.

• Economical and Efficient

• Compared to manual cleaning, the CIP cleaning system reduces cleaning time, increases efficiency, and optimizes the use of water, chemicals, and

• steam. This ensures rational energy use and significantly lowers cleaning costs.

• Safe and Reliable

• Concentrated acid and alkali solutions are stored in buried tanks. Tank liquid levels are automatically controlled and equipped with overflow protection. A

• specially designed outlet prevents crystallization and pipeline blockages.

• Mature PLC Control System

• Years of experience combined with high-quality imported control components ensure long-term stable operation. The user-friendly interface reduces

• operator training time and visually displays critical equipment status. An intuitive help interface assists operators in troubleshooting and restoring normal

• operation quickly.

Pricing Overview

The cost of a CIP cleaning system varies depending on capacity, automation level, and additional features. Smaller semi-automatic units are affordable for limited production, while fully automated CIP clean in place system models with multiple tanks, advanced PLC controls, and integrated chemical dosing are higher in price. Investing in a quality CIP tank cleaning system ensures reliable performance, consistent cleaning, and reduced labor costs, making it a cost-effective solution for industrial facilities.

The minute vertical CIP system is a compact, efficient, and highly reliable CIP washing system that ensures complete sanitation of tanks, vessels, and pipelines. From small-scale production to industrial applications, this CIP system delivers consistent cleaning, reduces downtime, and maintains high hygiene standards. Its advanced automation, vertical design, and robust construction make it an indispensable tool for industries where cleanliness and operational efficiency are critical.