Multifunctional Alcohol Recovery Concentrator

Multifunctional Alcohol Recovery Concentrator

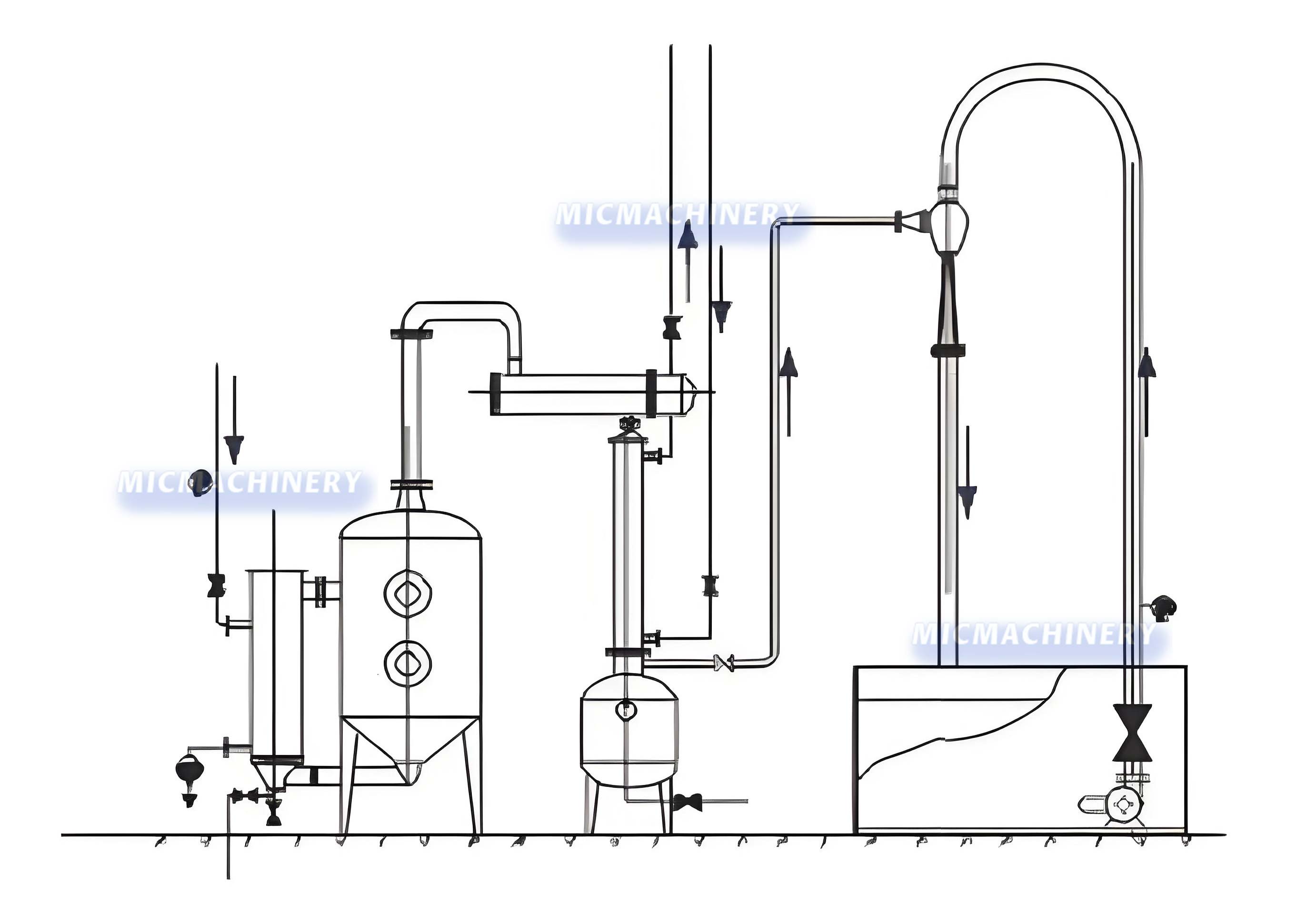

The multifunctional alcohol recovery concentrator is widely used in pharmaceutical, food, chemical, and herbal extraction industries. Its purpose is to separate, purify, and concentrate valuable substances while effectively recovering alcohol and other solvents. This ensures maximum material utilization, reduced production costs, and eco-friendly processing.

Key Features

1. Alcohol recovery: With high recovery capacity, vacuum operation method is adopted, and the process flow of the equipment is improved. The recovery rate can reach over 90%, resulting in an alcohol loss rate of less than 8%. Reduce energy consumption by 30%, with the characteristics of low investment and high recovery efficiency.

2. Concentrated liquid material: Adopting external circulation and vacuum negative pressure evaporation method, the evaporation speed is fast and the concentration density is high (1.2-1.35). Easy to operate, small footprint, beautiful appearance, heater, evaporator, and insulation are complete before leaving the factory. The outer layer of insulation is made of stainless steel sheet for protection, which meets GMP requirements.

Applications

The multifunctional alcohol recovery concentrator is ideal for:

• Pharmaceutical Industry – Extracting and concentrating herbal medicines, recovering alcohol, and preparing active ingredients.

• Food Industry – Concentrating flavors, natural extracts, and essences with consistent quality.

• Chemical Industry – Purifying chemical solutions, recovering solvents, and preparing high-purity products.

• Herbal Extraction – Widely used in traditional medicine production for efficient recovery of alcohol and plant-based solutions.

Advantages

• Significant reduction in raw material loss.

• Cost-effective operation with high solvent recovery rates.

• Seamless integration with China auxiliary equipment for large-scale processing.

• Customizable capacity to meet different industrial needs.

• Reliable, stable performance for continuous production.

Why Choose This Equipment?

When selecting processing machinery, investing in a multifunctional alcohol recovery concentrator ensures maximum efficiency and long-term value. As an indispensable part of a complete production line, it works in harmony with other auxiliary equipment, providing businesses with reliable performance and consistent output. For companies seeking dependable solutions, sourcing from trusted China auxiliary equipment manufacturers guarantees both quality and cost-effectiveness.

| Specification | MIC-500 | MIC-1000 | MIC-1500 |

| Evaporatlon quantity (kg/h) | 500 | 1000 | 1500 |

| Alcohol recovery | 50%-60% | 50%-60% | 50%-60% |

| The amount recovered (kg/h) | 300 | 600 | 1000 |

| Steam pressure (Mpa) | <0.09 | ||

| Vacuum (mmHg) | 0.02~0.08 | ||

| Heating area (㎡) | 8 | 16 | 22 |

| Evaporation chamber volume (m³) | 1.0 | 1.5 | 2 |

| Condensation area (㎡) | 18 | 36 | 50 |

| Cooling area (㎡) | 5 | 8 | 10 |

| Consumption of steam (kg/h) | 580 | 1150 | 1725 |

| Equipments weight (Kg) | 1350 | 1900 | 2900 |