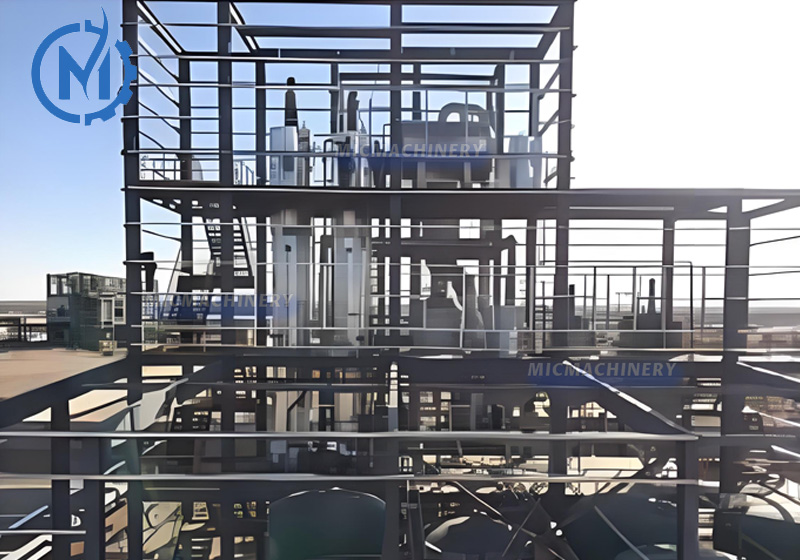

MVR-DTB Continuous Crystallizer

MVR-DTB Continuous Crystallizer – Efficient Industrial System

An MVR-DTB continuous crystallizer combines an MVR system with the DTB crystallization system. The DTB crystallizer is highly efficient, and years of operational experience show that it performs well, producing large crystals (600–1200 μm), is highly productive, and resistant to encrustation, making it a widely used type of continuous crystallizer. It can be applied to vacuum cooling, evaporation, and reaction-based crystallizations.

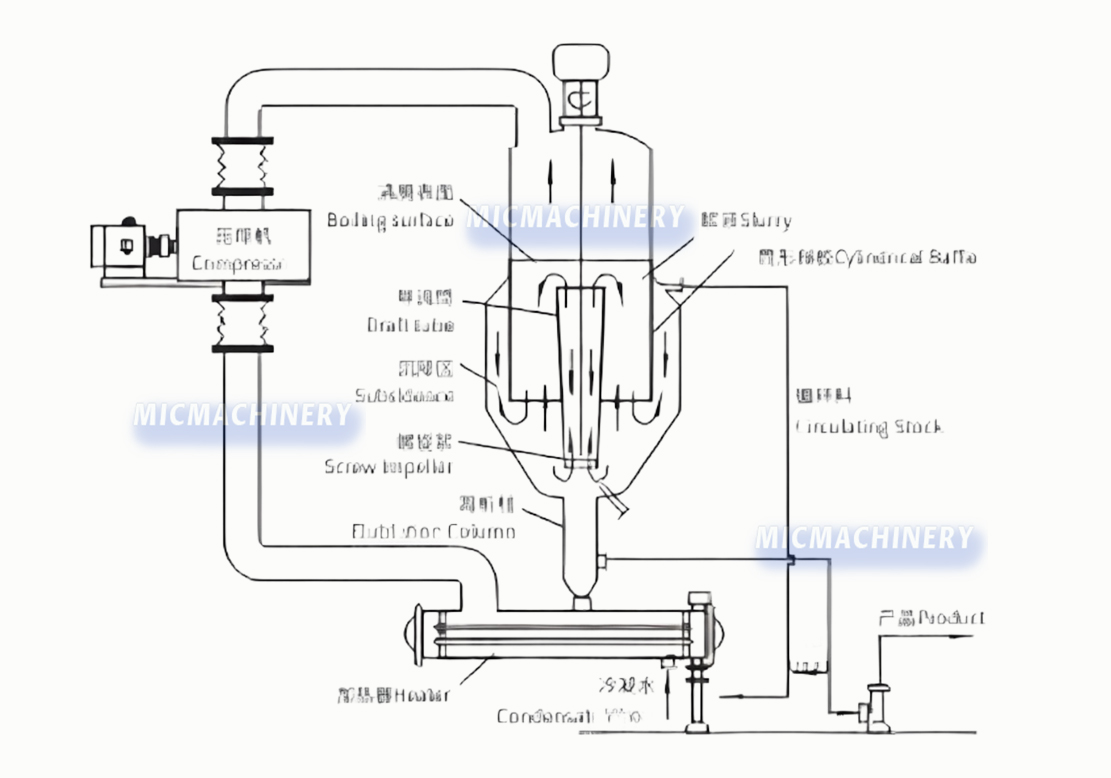

In the middle of the DTB crystallizer, a draft tube is surrounded by a circular baffle. Driven by a screw propeller, the fluid rises inside the tube to the edge, then turns back to the bottom along the annular channel formed by the draft tube and the baffle, and is recirculated into the bottom of the draft tube. This cycle repeats continuously, creating optimal conditions for crystallization.

This type of crystallizer effectively clears mother liquor overflow and eliminates fine grains. When coupled with the MVR system, it produces crystals with better granularity and higher energy efficiency.

Key Features

• Uniform Crystal Growth: Optimized suspension and separation zones ensure consistent crystal size and prevent agglomeration.

• Continuous Production: Designed for uninterrupted operation, reducing downtime and maximizing productivity.

• Energy Efficiency: Advanced heat recovery and MVR technology lower energy consumption and operating costs.

• Durable Construction: High-quality materials ensure long-term reliability and corrosion resistance.

• Customizable Design: Specifications can be tailored to meet various production capacities and process requirements.

Advantages

• As a type of continuous crystallizer equipment, it provides precise control over supersaturation and crystal size distribution.

• The continuous crystallizer enables seamless integration into industrial production lines, improving process stability and product uniformity.

• Offers reduced labor intensity and simplified operation through automation and intelligent process control.

Applications

The MVR-DTB continuous crystallizer is suitable for:

• Chemical production, including salts and specialty compounds

• Pharmaceutical intermediates and APIs

• Food processing and nutrition additive production

• Fertilizer and inorganic salts manufacturing

The MVR-DTB continuous crystallizer combines advanced engineering, energy-saving technology, and reliable performance to deliver high-quality crystals for demanding industrial applications.