MVR-OSLO Continuous Crystallizer

MVR-OSLO Continuous Crystallizer – High Efficiency System

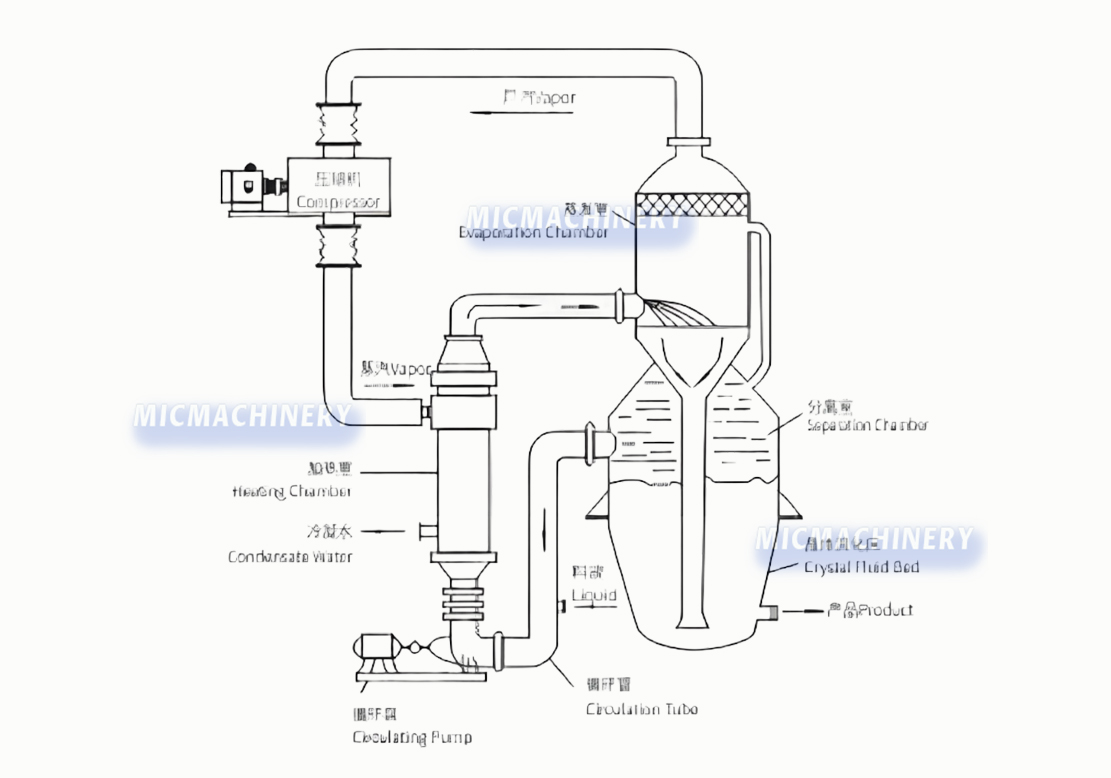

An MVR-OSLO continuous crystallizer combines the MVR system with the OSLO crystallization system. The OSLO crystallizer was proposed by a Norwegian named Jeremiassen in the 1930s, and it is often referred to as the Krystal crystallizer or size-grading crystallizer.

After entering the system, the liquid flows into the evaporator by means of a circulating pump and is heated to evaporate. The generated vapor then enters the evaporation chamber, where the concentrate separated from the secondary vapor is delivered through the central downflow line to the bottom, where crystals grow. The liquid then passes upward through the crystal fluid bed to avoid supersaturation. In this way, the crystals in the bed gradually grow and are discharged from the outlet once they reach the required size.

The secondary vapor increases in temperature and pressure through the MVR system and is subsequently recovered for reuse. This design makes full use of the latent heat during evaporation and therefore achieves the goal of energy savings.

Key Features

• Uniform Crystal Growth: Suspension and fluidization zones promote steady crystal enlargement while preventing unwanted agglomeration.

• Continuous Productivity: Designed for uninterrupted operation, reducing downtime and increasing overall process efficiency.

• Energy Efficiency: Incorporates advanced heat recovery technology for reduced energy consumption.

• Robust Design: Built with durable materials, ensuring long-term performance even in demanding industrial applications.

• Flexible Customization: Tailored specifications available to meet different process needs and production capacities.

Advantages

• As a type of continuous crystallizer equipment, it provides excellent control of supersaturation and crystal size distribution, resulting in high-purity products.

• The continuous crystallizer offers scalability for both pilot-scale testing and full-scale industrial production, making it versatile for multiple industries.

• Operators benefit from simplified process control, easy maintenance, and a reliable system that improves production consistency and product yield.

Applications

The MVR-OSLO continuous crystallizer is ideal for industries requiring large-scale, high-quality crystal production, including:

• Fine chemicals and specialty materials

• Pharmaceutical intermediates and active ingredients

• Food and nutrition additives

• Fertilizer and inorganic salt production