MIC Semi-Automatic Beverage Sealing Machine (15CPM)

MIC Semi-Automatic Beverage Sealing Machine

Mic Machinery is a leading manufacturer of advanced beverage packaging equipment, committed to delivering high-quality solutions to the global market. With years of experience in the industry, we specialize in filling and sealing systems that combine precision engineering and user-friendly design. Our core product range includes filling lines, capping units, and the trusted semi-automatic beverage sealing machine tailored for small to medium-sized production facilities.

|

|

Machine This compact and modern beer canning machine features a sleek white design with a transparent viewing area and an intuitive control panel. Its clean and professional appearance suits breweries and beverage businesses, ensuring functionality with aesthetic appeal. |

|

Control Panel The control panel of our beer canning machine is designed for ease of use, offering intuitive controls. |

|

|

|

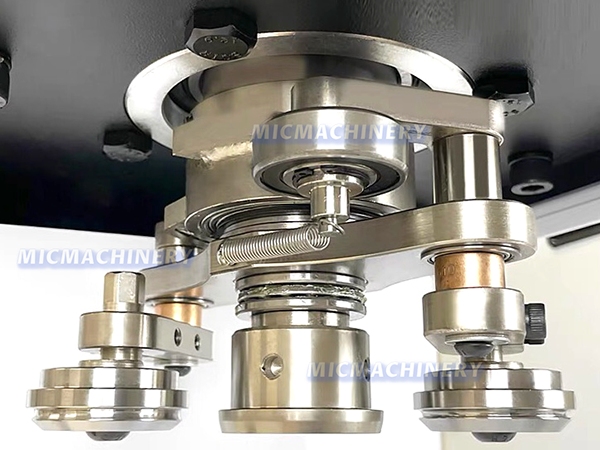

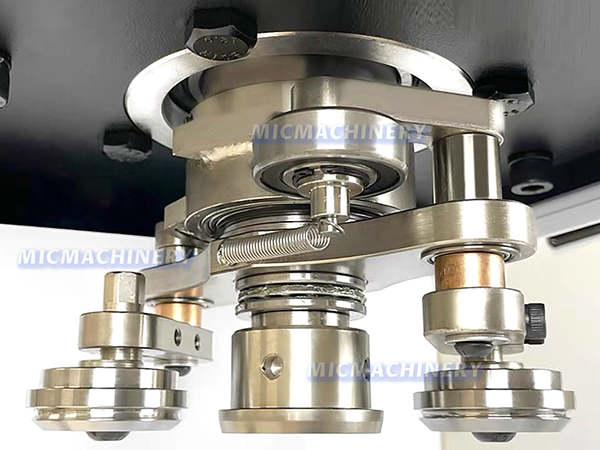

Capping Station A Capping Station is an essential part of the filling and packaging process, designed to securely apply caps to jars, or cans, ensuring product safety and preventing leaks or contamination. |

Working Principle

The MIC Semi-Automatic Beverage Sealing Machine operates using a streamlined manual-automated hybrid process designed to minimize operator effort while maximizing seal accuracy. The procedure includes:

1)Can placement: The operator manually places the filled beverage container onto the sealing platform.

2)Securing the container: The adjustable locking arm secures the container to maintain its position.

3)Sealing activation: When the operator initiates the cycle, the sealing head lowers to apply pressure and rotational motion, sealing the lid tightly.

4)Completion and removal: The container is then released and removed, ready for downstream packaging.

This reliable process protects product freshness and prevents spillage or leakage during transport and storage.

Functional Advantages

The beverage sealing machine is engineered with efficiency and simplicity in mind. Key features include:

▪ Compact, stainless-steel structure suited for space-limited operations

▪ Compatible with a wide range of can sizes

▪ Precise, adjustable sealing head for airtight closure

▪ User-friendly controls with minimal training required

▪ Seamless integration with existing beverage filling machine setups

▪ Ideal for short production runs, seasonal beverages, and startups

Thanks to its versatility, this unit helps bridge the gap between manual labor and full automation.

Applications

This semi-automatic beverage sealing machine is ideal for small beverage manufacturers, research labs, food startups, and pilot production lines. It pairs effortlessly with a beverage filling machine to form a complete, compact production solution for juices, soft drinks, energy drinks, and flavored waters. The machine supports flexible container types, making it valuable in facilities producing varied beverage types in small batches.

Conclusion

The MIC Semi-Automatic Beverage Sealing Machine offers an efficient, cost-effective solution for small to mid-sized beverage producers. Its simple operation, durable construction, and consistent sealing quality make it a reliable addition to any beverage sealing machine line. Whether you're launching a new product or scaling a boutique brand, Mic Machinery delivers dependable tools to help you succeed.

| Weight | 52kg |

| Voltage | 220V 50Hz |

| Packaging Type | CANS, Bottles |

| Dimension | 255*455*608mm |

| Motor power | 0.55KW |

| Filling speed | 15 cans each minute |