MIC Semi-Automatic Carbonated Drink Sealing Line (15CPM)

MIC Semi-Automatic Carbonated Drink Sealing Line(30CPM)

Company Introduction

Jiangsu MIC Machinery is a leading manufacturer of beverage packaging equipment, dedicated to providing efficient, durable, and user-friendly machines for small and medium-sized beverage producers. Our equipment is widely used in soda, beer, and other sparkling beverages, earning a strong reputation across global markets. We focus on innovation and quality, helping our clients build reliable carbonated drink sealing line setups that meet industry standards.

|

|

Machine This compact and modern beer canning machine features a sleek white design with a transparent viewing area and an intuitive control panel. Its clean and professional appearance suits breweries and beverage businesses, ensuring functionality with aesthetic appeal. |

|

Control Panel The control panel of our beer canning machine is designed for ease of use, offering intuitive controls. |

|

|

|

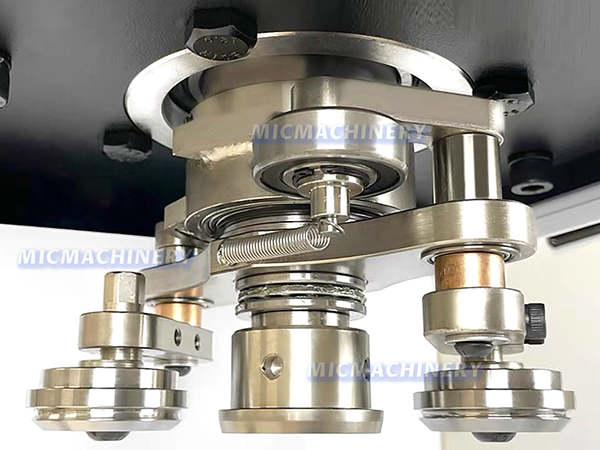

Capping Station A Capping Station is an essential part of the filling and packaging process, designed to securely apply caps to bottles, jars, or cans, ensuring product safety and preventing leaks or contamination. |

Working Principle

The MIC Semi-Automatic Carbonated Drink Sealing Line (30CPM) uses a streamlined manual-to-automatic sealing process designed for stable operation and product preservation. Below is a step-by-step breakdown:

1)Manual Can Placement

The operator manually places the pre-filled aluminum can or glass bottle onto the machine’s base platform.

2)Container Positioning

The machine clamps the container in place using a height-adjustable locking mechanism to ensure alignment with the sealing head.

3)Automatic Sealing Activation

Once positioned, the machine activates the sealing head, which applies consistent pressure and rotational force to seal the lid tightly. This ensures carbonation retention.

4)Sealing Completion and Release

After sealing, the head retracts automatically. The operator then removes the sealed product, and the system is ready for the next cycle.

This controlled, repeatable process is highly suitable for applications within a soda can production line or compact carbonated drink sealing line requiring quality and speed.

Functions and Advantages

This semi-automatic sealing system is ideal for soda, beer, kombucha, and other fizzy drinks. Whether used alone or integrated into a drink production line, it offers several advantages:

▪ 30 cans per minute sealing capacity – perfect for small-scale production

▪ Compact footprint for easy placement in limited spaces

▪ Versatile compatibility with both cans and bottles

▪ Adjustable pressure settings for various container types

▪ Stainless steel structure for hygienic, corrosion-resistant performance

▪ User-friendly controls for quick training and low maintenance

The machine’s flexibility and consistency make it a strong addition to production environments where cost efficiency and reliability are key.

Application Scenarios

This equipment is widely used in boutique soda factories, craft breweries, beverage R&D facilities, and start-up bottling lines. It is ideal for operations that need flexibility, fast changeovers, and dependable sealing quality without full automation. Whether operating as a standalone unit or integrated into a drink production line, this system delivers reliable performance with minimal operator input. It also functions as an excellent component within a soda can production line aiming for efficient small-batch output.

Conclusion

The MIC Semi-Automatic Carbonated Drink Sealing Line (30CPM) offers beverage manufacturers a powerful, easy-to-use solution for precise sealing. Built to support flexible configurations, it can seamlessly fit into any small-scale carbonated drink sealing line or complement a modular soda can production line setup. MIC Machinery continues to support clients with practical, durable equipment that keeps production smooth and beverages fresh.

| Weight | 52kg |

| Voltage | 220V 50Hz |

| Packaging Type | CANS, Bottles |

| Dimension | 255*455*608mm |

| Motor power | 0.55KW |

| Filling speed | 15 cans each minute |