MIC Semi Automatic Soda Can Sealing Equipment (15CPM)

MIC Semi Automatic Soda Can Sealing Equipment

Mic Machinery is a leading manufacturer specializing in beverage packaging solutions. We provide innovative and reliable equipment designed for small to medium beverage producers worldwide. Our soda can sealing equipment is engineered to meet the needs of businesses seeking durable and efficient can sealing solutions.

|

Machine This compact and modern beer canning machine features a sleek white design with a transparent viewing area and an intuitive control panel. Its clean and professional appearance suits breweries and beverage businesses, ensuring functionality with aesthetic appeal. |

|

|

Control Panel The control panel of our beer canning machine is designed for ease of use, offering intuitive controls for adjusting filling speed and volume, ensuring efficient and precise operation. |

|

|

|

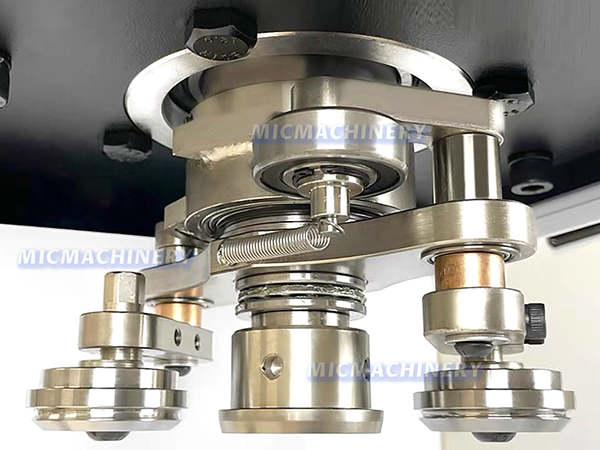

Capping Station A Capping Station is an essential part of the filling and packaging process, designed to securely apply caps to jars, or cans, ensuring product safety and preventing leaks or contamination. |

Working Principle

The MIC Semi Automatic Soda Can Sealing Equipment operates by combining manual can loading with automated sealing processes to ensure consistent quality:

1)The operator places a filled soda can onto the machine platform.

2)The lid is manually positioned on top of the can.

3)The machine clamps the can firmly and initiates the sealing cycle.

4)A rotary sealing head securely seals the can’s lid in place.

5)Once sealed, the can is released for packaging or further processing.

This semi-automatic process balances speed with precision, ensuring each can is perfectly sealed.

Functional Advantages

This soda canning equipment offers several key benefits:

▪ Robust stainless steel construction for hygiene and durability

▪ Adjustable settings to accommodate different can sizes

▪ Easy-to-use controls suitable for operators with minimal training

▪ Compact design ideal for limited production spaces

▪ Integration capability with other beverage filling machines

▪ Reliable sealing speed supporting small to medium production runs

Applications

Our soda canning machine for sale is widely used in craft soda production, carbonated water bottling, and beverage startups. It fits well in small beverage factories and pilot production lines where precision and efficiency are vital. This equipment ensures airtight sealing to preserve carbonation and maintain beverage quality.

Conclusion

The MIC Semi Automatic Soda Can Sealing Equipment is an ideal choice for businesses seeking cost-effective and reliable can sealing solutions. Designed to work seamlessly with other soda canning equipment, it supports efficient production while maintaining product freshness and integrity. Choose Mic Machinery for trusted soda packaging technology.

| Weight | 52kg |

| Voltage | 220V 50Hz |

| Packaging Type | CANS, Bottles |

| Dimension | 255*455*608mm |

| Motor power | 0.55KW |

| Filling speed | 15 cans each minute |