MIC Semi Automatic Soft Drink Sealing Machine (15CPM)

MIC Semi Automatic Soft Drink Sealing Machine

Mic Machinery is a trusted name in the beverage packaging industry, delivering innovative sealing and filling solutions worldwide. With over a decade of experience, we specialize in crafting reliable, efficient, and cost-effective machinery for beverage producers of all sizes. Our goal is to support growing businesses with scalable equipment that guarantees quality output while maintaining operational simplicity.

|

|

Machine This compact and modern beer canning machine features a sleek white design with a transparent viewing area and an intuitive control panel. Its clean and professional appearance suits breweries and beverage businesses, ensuring functionality with aesthetic appeal. |

|

Control Panel The control panel of our beer canning machine is designed for ease of use, offering intuitive controls. |

|

|

|

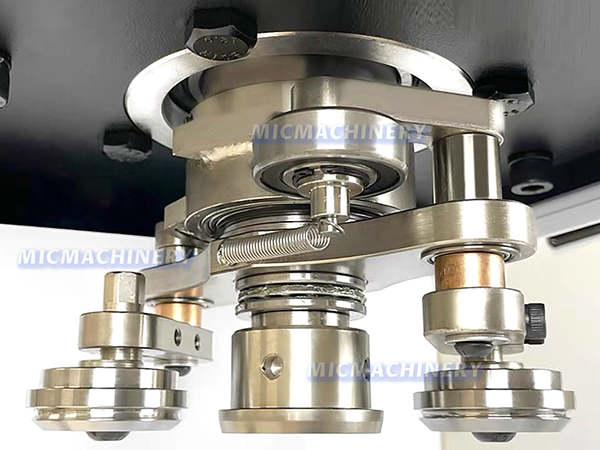

Capping Station A Capping Station is an essential part of the filling and packaging process, designed to securely apply caps to jars, or cans, ensuring product safety and preventing leaks or contamination. |

Working Principle

The semi automatic soft drink sealing machine operates through a step-by-step process:

1)Manual Can Placement: The operator loads empty or filled cans onto the platform.

2)Positioning & Alignment: The machine aligns the can precisely under the sealing head.

3)Sealing Head Activation: Once initiated, the sealing head descends to secure the lid.

4)Rotary Sealing Process: The lid is crimped onto the can body using a controlled rotary system.

5)Sealing Completion: The sealed can is ejected, ready for packaging or distribution.

Features and Advantages

The soft drink sealing machine offers exceptional reliability and performance. It’s built from stainless steel, ensuring hygiene and durability. Compact and easy to operate, it requires minimal maintenance. Key advantages include:

▪ Precise sealing for minimal gas loss

▪ Compatibility with standard can sizes

▪ Adjustable settings for different lid types

▪ High sealing consistency across batches

Applications

This machine is ideal for small to medium beverage producers, craft soda makers, and testing facilities. It integrates seamlessly with carbonated soft drink filling machine setups or stand-alone sealing operations. Whether you're producing sodas, flavored water, or other sparkling beverages, the system ensures optimal sealing quality.

Use in Beverage Lines

The equipment can be paired with manual or automated fillers to create a streamlined production setup. For businesses scaling up, it complements a basic filling line without needing full automation. When used with a carbonated soft drink filling machine, it forms a reliable and cost-effective solution for efficient production.

Conclusion

The semi automatic soft drink sealing machine from Mic Machinery is a valuable asset for businesses aiming to produce professionally sealed beverages on a manageable scale. Its performance, simplicity, and adaptability make it ideal for niche markets, startup brands, and regional beverage producers. Trust Mic Machinery to support your next step in production growth.

| Weight | 52kg |

| Voltage | 220V 50Hz |

| Packaging Type | CANS, Bottles |

| Dimension | 255*455*608mm |

| Motor power | 0.55KW |

| Filling speed | 15 cans each minute |