Single Effect Falling Film Evaporator

Single Effect Falling Film Evaporator

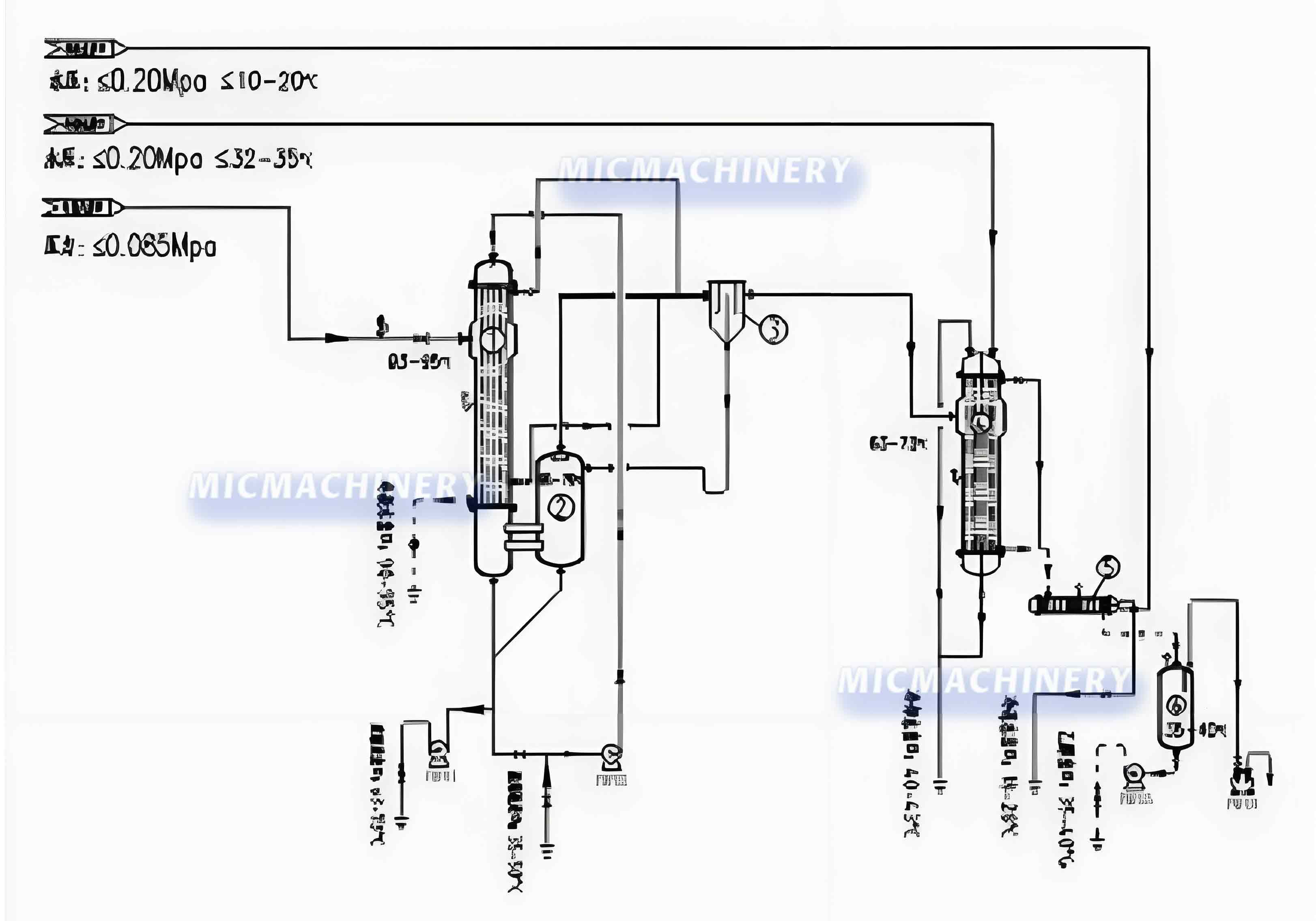

The single effect falling film evaporator is a high-performance concentration system widely used in the pharmaceutical, food, beverage, and chemical industries. Designed for efficiency, this equipment allows liquid materials to form a thin film while flowing downward along heated tubes, ensuring rapid evaporation, energy savings, and minimal product degradation.

Efficient Design for Superior Performance

As a specialized falling film evaporator, it ensures uniform heat transfer and gentle processing, making it ideal for heat-sensitive liquids such as milk, fruit juice, herbal extracts, and pharmaceutical solutions. Its vertical structure supports continuous operation, while its optimized design reduces scaling and cleaning time, guaranteeing stable and consistent output.

Trusted Manufacturing and Quality Assurance

Backed by experienced falling film evaporator manufacturers, this system is built with high-quality stainless steel for durability, corrosion resistance, and compliance with international standards. It is equipped with advanced controls for temperature, pressure, and flow rate, ensuring precision and safety throughout the evaporation process.

Key Features

1. Fully enclosed production, rapid, low-temperature evaporation, maintaining the natural color, aroma, and flavor of the product.

2. High heat transfer efficiency: Rapid material flow and strong anti-scaling capabilities.

3. Wide adjustable concentration ratio range: Because each effect can form a separate material circulation, the concentration ratio can be adjusted over a wide range.

4. The equipment is equipped with cleaning nozzles and a CIP internal cleaning system.

Applications

• Food and Beverage Industry: Concentrating juices, milk, and syrups

• Pharmaceutical Industry: Extracts, active ingredients, and herbal preparations

• Chemical Industry: Solvent concentration and recovery

By choosing this single effect falling film evaporator, you benefit from efficient concentration, long-term durability, and reliable performance. With the expertise of leading falling film evaporator manufacturers, this equipment is a cost-effective solution for modern production lines seeking higher efficiency and consistent product quality.

| Project | MIC-100 | MIC-200 | MIC-400 | MIC-600 | MIC-800 | MIC-1000 | MIC-1200 |

| Ethanol evaporation capacity (kg/h) | 100 | 200 | 400 | 600 | 800 | 1000 | 1200 |

| A Heating source medium | Steam | ||||||

| Raw steam pressure (Mpa) | 0.085 (Absolute pressure) | ||||||

| Steam heat consumption (kcal/h) | 30000 | 60000 | 120000 | 180000 | 240000 | 300000 | 360000 |

| B Heating source medium | Heat transfer oil | ||||||

| Heat transfer oil inlet and outlet temperature (°C) | 120-130/100-110 | ||||||

| Heat consumption of heat transfer oil (kcal/h) | 31000 | 62000 | 124000 | 186000 | 248000 | 310000 | 372000 |

| Working pressure of heat transfer oil (Mpa) | 0.15-0.20 | ||||||

| Evaporation temperature (°C) | 65-75 | ||||||

| Ethanol discharge temperature (°C) | 35-40 | ||||||

| Concentrate discharge temperature (°C) | 63-73 | ||||||

| Vacuum (-Mpa) | 0.065-0.077 | ||||||

| Heating area (㎡) | 3.0 | 6.0 | 12 | 18 | 24 | 30 | 36 |

| Condensing area (㎡) | 6.0 | 12 | 24 | 36 | 48 | 60 | 72 |

| Condenser working pressure (Mpa) | 0.20-0.25 | ||||||

| Cooling area (㎡) | 2.0 | 3.0 | 4.0 | 5.0 | 6.0 | 8.0 | 10 |

| Cooler working pressure (Mpa) | 0.15-0.20 | ||||||

| Cooling water circulation (t/h) | 3.8 | 7.6 | 17 | 24 | 32 | 39 | 47 |

| Cooling water working pressure (Mpa) | 0.20-0.25 | ||||||

| Cooling water inlet and outlet temperature (°C) | 32-35/40-43 | ||||||

| Chilled water consumption (kcal/h) | 1500 | 3000 | 6000 | 9000 | 12000 | 15000 | 18000 |

| Chilled water inlet and outlet temperature (°C) | 10-20/18-28 | ||||||

| Chilled water working pressure (Mpa) | 0.15-0.20 | ||||||

| Total installed power (kw/h) | 3.75 | 5.55 | 6.6 | 8.7 | 10.7 | 12.5 | 14.25 |