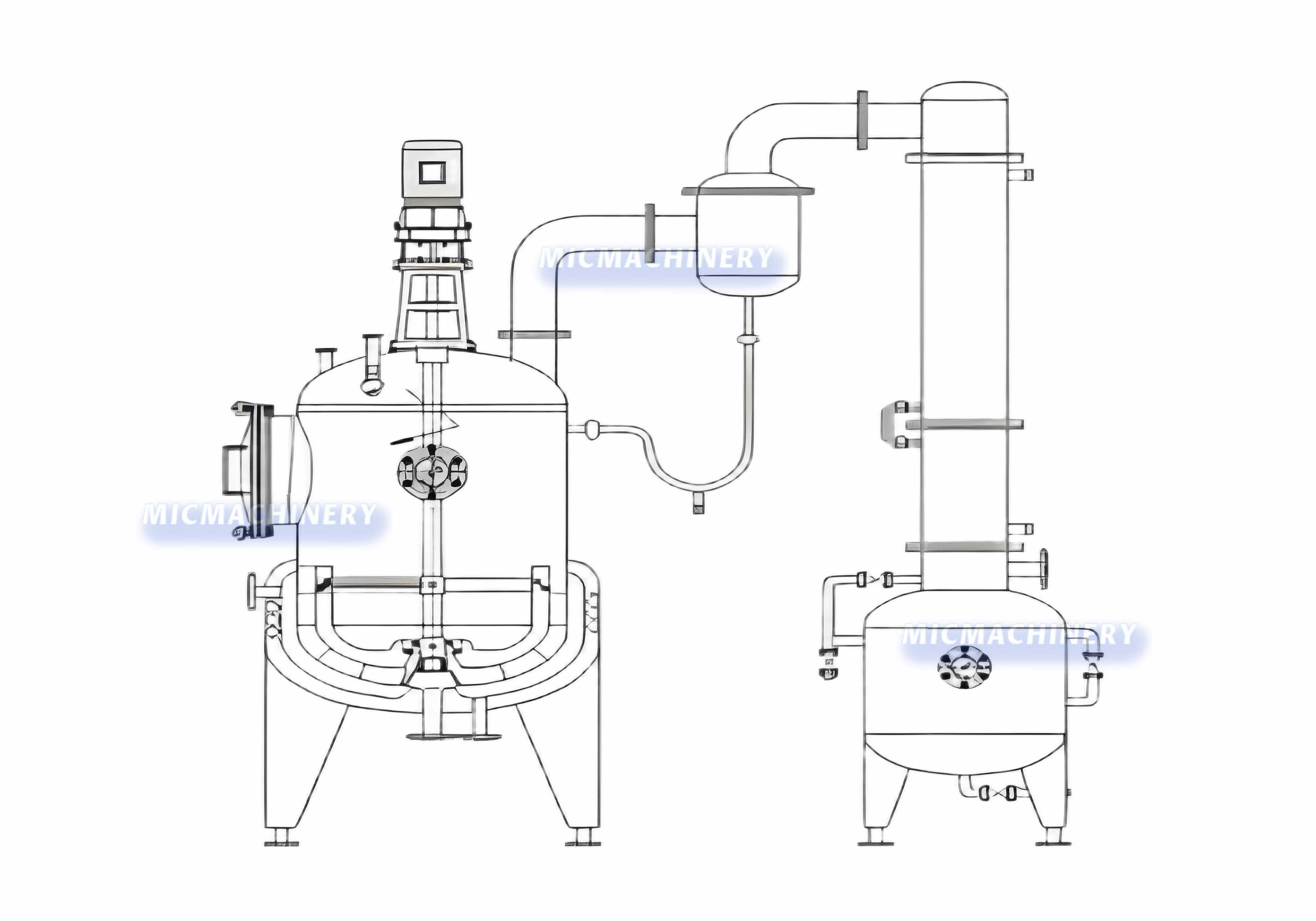

Vacuum Pressure Reducing Concentration Tank

Vacuum Pressure Reducing Concentration Tank for Efficient Processing

The vacuum pressure reducing concentration tank is an advanced piece of equipment designed for efficient liquid concentration under reduced pressure. This technology minimizes heat damage to sensitive materials, ensuring higher product quality while saving energy. It is widely used in industries such as food, beverage, dairy, chemical, and pharmaceuticals.

Key Features

• Vacuum concentration allows operation at lower temperatures, preserving flavor, nutrients, and active compounds.

• Stainless steel construction provides excellent corrosion resistance and long service life.

• Automatic controls make operation stable, safe, and reliable.

• Easy cleaning and maintenance, ensuring compliance with hygienic standards.

Applications

The concentration tank is commonly used for condensing fruit juices, dairy products, herbal extracts, and chemical solutions. By reducing processing temperature and time, it helps maintain the natural color, aroma, and nutritional content of the final product.

Benefits of the Vacuum Pressure Reducing Concentration Tank

• Maintains product quality during the evaporation process.

• Reduces energy consumption compared with conventional methods.

• Increases production efficiency and output stability.

• Flexible design suitable for various production needs.

Your Trusted Partner in Processing Solutions

As one of the leading auxiliary equipment manufacturers, we specialize in delivering reliable, durable, and high-performance processing equipment. Our concentrate tank and concentration tank systems are designed to meet international standards, making us a preferred choice for companies seeking efficiency and quality.

By choosing us, you are working with an auxiliary equipment manufacturer that provides not only the machine itself but also professional technical support and after-sales service.

| Model | MIC-50 | MIC-100 | MIC-200 | MIC-300 | MIC-500 | MIC-700 | MIC-1000 | |

| Volume (L) | 50 | 100 | 200 | 300 | 500 | 700 | 1000 | |

| Evaporation capacity (kg/h) | 20 | 40 | 60 | 80 | 100 | 130 | 160 | |

| Dissotved by the liquid poot volume (L) | 15 | 45 | 60 | 76 | 100 | 125 | 165 | |

| Pressure in jacket | <0.09 | |||||||

| Vacuum (mmHg) | 600~700 | |||||||

| Heating area (㎡) | 0.25 | 0.59 | 0.8 | 1.1 | 1.45 | 1.8 | 2.2 | |

| Cooling area (㎡) | 1.2 | 1.7 | 2.4 | 3.0 | 3.3 | 3.6 | 4.1 | |

| Condensation area (㎡) | 0.29 | 0.35 | 0.45 | 0.6 | 0.7 | 0.85 | 1.05 | |

| Equipments weight (kg) | 380 | 550 | 550 | 650 | 800 | 1000 | 1450 | |

| Dimensions (mm) | Long | 1200 | 1700 | 1700 | 1700 | 2100 | 2400 | 2390 |

| Wide | 600 | 800 | 800 | 1000 | 1200 | 1300 | 1300 | |

| High | 2200 | 2700 | 2700 | 3400 | 3400 | 3400 | 3720 | |