Wet Glue Labeling Machine

Mechanical Introduction of the Wet Glue Labeling Machine

The wet glue labeling machine is a traditional yet highly efficient solution widely used in labeling operations for glass bottles, cans, jars, and other rigid containers. Designed for precision and speed, the wet glue labeling machine utilizes a glue roller system to apply a thin layer of cold glue to paper labels, which are then wrapped around the container surface with smooth and secure adhesion.

|

This machine adopts frequency conversion speed regulation, PLC control, wide range of speed regulation, stable and reliable speed regulation, strong programmable control function, high degree of automation, and equipped with Ethernet module, Ethernet on-line control. | |

|

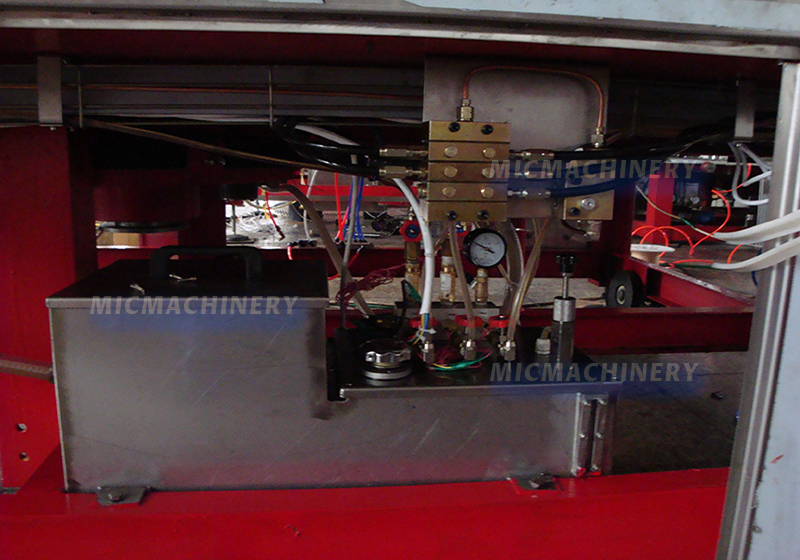

Using a stable roller glue equipment, obtaining and releasing label run smooth and reliable. Glue brushing will be much more even, efficient and glue-saving. |

|

|

|

Rotary cam-controlled bottle turning plate, the operation is smooth and reliable, High precision of bottle transposing control, accurate labeling, glue brushing even and stable, which can meet the labeling of round bottles, square bottles and various special-shaped bottles. This structure won national patent | |

| It adopts stainless steel rubber roller and glue-brushing integrated label pallet, and the service life is guaranteed for one year without opening and deformation. |  |

|

|

The lubrication principle of the automobile engine is adopted. The label station and the turntableuse the pump station to supply oil for cyclic lubrication, which realizes the function of lubricating the equipment before running. It solves the problem of starting the vehicle first before starting the lubrication. And, the pump station is equipped with safety protection functions. When the pressure and flow are not enough, the machine cannot be started to avoid oil shortage due to operator negligence, which prolongs the service life. This design is ahead of the standard machine industry, and has obtained national patent |

Mechanical Performance and Design

This wet glue labeling machine operates on a fully mechanical drive system synchronized by cams and gears, ensuring consistent labeling results even in high-speed environments. Equipped with a rotating drum and precise label pick-up mechanism, the machine efficiently transfers glue from the glue roller to the label and applies it onto the product surface without misalignment or wrinkling.

As a reliable cold glue labeling machine, it is ideal for applications where paper labels are required, especially in industries such as food and beverage, chemical, liquor, and pharmaceuticals. Its classic glue system guarantees a cost-effective solution for large-volume labeling with low operating costs.

Key Features of the Wet Glue Labeling Machine:

-

Compatible with cylindrical, square, and uniquely shaped bottles.

-

High-speed labeling ranging from 60 to 400 bottles per minute.

-

Sturdy stainless steel frame and anti-corrosion components.

-

Adjustable bottle feeding and label placement systems.

-

Integrated safety guards and overload protection for safe operation.

Versatility and Application

This cold glue labeling machine is especially suitable for customers preferring eco-friendly labeling solutions, as it supports recyclable paper labels and water-soluble glue. Its compatibility with a wide variety of containers makes it the preferred cold glue labeler for breweries, distilleries, and condiment manufacturers.

Conclusion

In summary, the wet glue labeling machine is a dependable and time-tested system that combines mechanical precision with low-cost operation. Whether you're upgrading your existing cold glue labeling machine or installing a new cold glue labeler, this equipment offers the speed, stability, and affordability to meet demanding production line requirements. Its reliable structure and proven technology make it a valuable asset in modern labeling operations.

The machine is equipped with manual control and automatic control. Under the automatic state, the equipment can automatically adjust the productivity according to the accumulation state of bottles in and out of the bottle feeding line, and operate at low speed according to the bottle-stopping state to empty the bottles in the equipment.

The machine is equipped with the functions of bottle inlet protection, bottle outlet stacking protection, host overload protection, safety door opening and stopping protection, lubrication pressure detection and alarm function, which cannot be started without pressure;It also has the function of non-standard stop of the back label to prevent the rework without standard due to the operator's failure to look after.