Wrapping Machine for Pallets

Introduction to the Wrapping Machine for Pallets

At Jiangsu Mic Machinery, we specialize in providing top-quality packaging solutions, including the wrapping machine for pallets. Our advanced machines are designed to streamline your pallet packaging process, ensuring maximum efficiency and load stability. Whether you are looking for an automatic or manual solution, our machines are engineered to meet the diverse needs of businesses across various industries.

Machine Information

The pallet wrapping machine offers a high-performance, reliable solution for securely wrapping pallets with stretch film. By automating the wrapping process, it reduces the risk of human error and increases productivity in packaging operations. The machine is designed to handle different pallet sizes and weights, making it versatile enough for both small and large-scale operations. With adjustable wrap settings, users can customize the wrapping tension, number of layers, and speed to suit specific packaging requirements.

Main Components and Functions

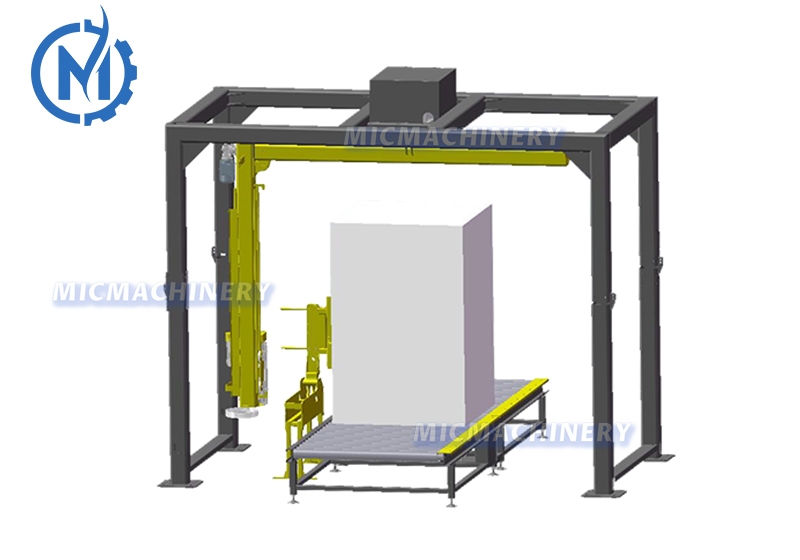

The automatic pallet wrapping machine is built with several key components that work together to ensure optimal performance:

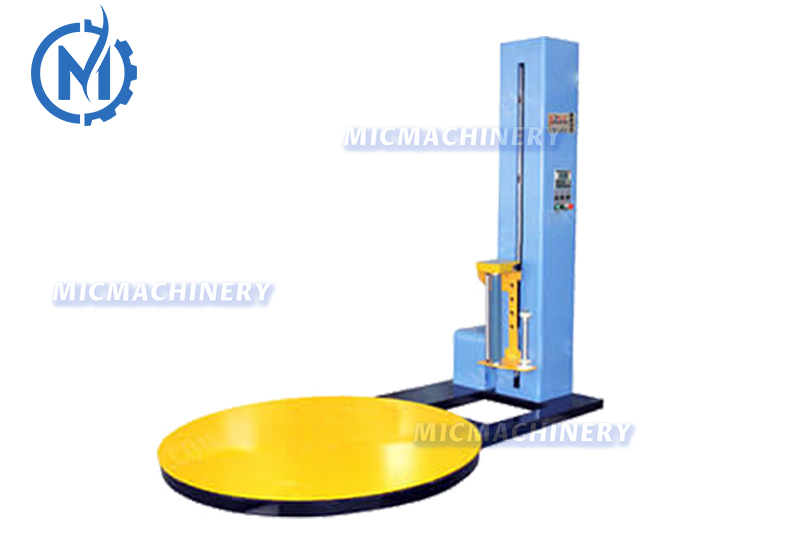

Turntable: The turntable rotates the pallet smoothly and consistently, allowing the film to wrap the pallet evenly from top to bottom.

Film Dispenser: The film dispenser ensures that the stretch film is fed evenly around the pallet, maintaining constant tension for a secure wrap.

Control Panel: The user-friendly control panel enables operators to adjust settings, such as film tension, wrap speed, and the number of wraps, allowing full customization based on the load requirements.

Safety Sensors: Integrated safety sensors detect irregularities in the wrapping process, ensuring the machine halts immediately if an issue arises, preventing potential damage to both the machine and the load.

Film Clamps and Cutters: These components work together to neatly cut the stretch film once the wrapping is complete, ensuring a clean finish and preventing unnecessary film waste.

Conclusion

Jiangsu Mic Machinery's wrapping machine for pallets provides a powerful, efficient, and cost-effective solution for secure pallet packaging. The pallet wrapping machine offers enhanced productivity and reliability, while the automatic pallet wrapping machine takes the burden of manual wrapping off your team, allowing for quicker turnaround times and reduced labor costs. With high-quality components and customizable features, our machines are designed to meet the diverse needs of businesses, ensuring long-term value and operational efficiency. Trust Jiangsu Mic Machinery to deliver a superior packaging solution tailored to your business needs.

|

Turntable diamete: |

2000mm |

|

Turntable height: |

500mm |

|

Conveying speed: |

2~14r/min adjustable |

|

Film frame lifting speed: |

1~3m/min |

|

Stretch film width: |

500mm; thickness 12-35μ |

|

Stretch film inner and outer diameter: |

inner diameter 76mm, outer diameter maximum 350mm |

|

Turntable load capacity: |

1500 kg |

|

Maximum packaging height: |

2100mm (including pallet height) |

|

Conveying motor power: |

0.75kw |

|

Turntable motor power: |

1.5kw |

|

Lifting motor power: |

0.37kw |

|

Pre-tensioning motor power: |

0.23KW |

|

Air pressure: |

0.4-0.7MP |

|

Power supply voltage: |

220/50hz |

|

Machine weight: |

1200kg |

|

Turntable speed: |

0-15 rpm |

|

Packing adaptability size: |

L1200×W1200×H2100mm |

|

Effective width of table conveyor: |

1280mm |

|

Turntable load-bearing capacity: |

1500kg |

|

1. Body: |

Q235-5.0mm plate is bent and the surface is sprayed with plastic |

|

2. Tripod: |

80*40mm carbon steel square tube is welded and the surface is sprayed with plastic |

|

3. Chain conveyor size: |

2500*1700*500MM (layout according to the plan) |

|

4. Table height: |

500MM |

|

5. Conveyor speed: |

1-10 meters variable frequency adjustable |

|

6. Motor: |

Chengbang (Taiwan) |

|

7. Chain material: |

stainless steel |

|

8. Chain: |

Donghua chain |

|

9. Inverter: |

Delta (Taiwan) |

|

10. Foot plate: |

stainless steel |

|

11. Sprocket: |

carbon steel, black surface, tooth surface quenching treatment |

|

PLC |

(Delta) |

(Taiwan) |

|

Touch screen |

(Wei Lun) |

(Taiwan) |

|

Lifting inverter |

(Delta) |

(Taiwan) |

|

Turntable inverter |

(Delta) |

(Taiwan) |

|

Pre-tension inverter |

(Delta) |

(Taiwan) |

|

AC contactor SCHNEIDER |

(Schneider) |

(France) |

|

Emergency stop switch SCHNEIDER |

(Schneider) |

(France) |

|

Travel switch SCHNEIDER |

(Schneider) |

(France) |

|

Photoelectric switch |

(Pepperl+Fuchs) |

(Germany) |

|

Proximity switch |

(Yang Ming) |

(Taiwan) |

|

Turntable reducer |

(Chengbang) |

(Taiwan) |

|

Column lifting motor |

(Jinlong) |

(China) |

|

Conveying reducer |

(Chengbang) |

(Taiwan) |

|

Mold frame motor |

(Chenggang) |

(Taiwan) |