MIC 12-1 Beer Filling Machine (1000-2000CPH)

Introduction to the MIC 12-1 Beer Filling Machine: Efficient, Reliable, and Advanced

At Jiangsu Mic Machinery, we are committed to providing high-quality solutions for the beverage industry. Our MIC 12-1 beer filling machine (1000-2000CPH) is designed to meet the demands of modern beer production, offering superior efficiency, accuracy, and versatility. As a leader in the field of beverage machinery, we specialize in manufacturing advanced beer filling machine and beer packaging machine that optimize the production process and enhance the quality of the final product.

|

|

Inline Can Rinser / Can Washing Machine |

|

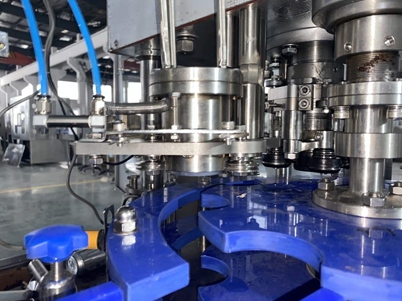

Isobaric Pressure/ Counter Pressure Filling System

The isobaric pressurefilling system is designed for filling carbonated beverages like beer without excessive foaming or loss of carbonation. It works by equalizing the pressure between the product tank and the empty can or bottle before filling begins. This controlled environment ensures accurate filling levels, preserves carbonation, and minimizes oxygen exposure, which helps maintain product freshness and quality. |

|

|

|

Aluminum Lid Seaming System

The aluminum lid seaming system is responsible for securely sealing cans after filling. It uses a rotating seaming head to crimp the aluminum lid tightly onto the can body, forming a leak-proof and airtight seal. This system ensures high-speed, consistent sealing performance, which is critical for maintaining carbonation, freshness, and preventing contamination in canned beverages. |

Key Features of the MIC 12-1 Beer Filling Machine

The MIC 12-1 is an automatic beer filler that excels in high-speed filling operations, handling up to 2000 cans per hour. This machine is equipped with cutting-edge technology to ensure precise and consistent beer filling, making it an ideal choice for breweries of all sizes.

1. High Efficiency

With a filling capacity ranging from 1000 to 2000 cans per hour, the automatic beer filler is designed to maximize production efficiency while maintaining the integrity of the product. The high-speed operation reduces downtime, increasing the overall output of your brewery.

2. Advanced Filling Technology

The beer filling machine uses a gravity filling system, ensuring that the beer is filled accurately and consistently without spillage or foam overflow. This precision minimizes wastage and ensures that each can is filled to the correct level, preserving both the product’s quality and brand presentation.

3. Versatile Compatibility

The MIC 12-1 is highly adaptable, capable of filling various sizes of cans. Its flexibility makes it suitable for a wide range of beer types and packaging formats, allowing for easy integration into existing production lines.

4. Fully Automated Operation

As an automatic beer filler, the MIC 12-1 minimizes the need for manual labor, reducing human error and enhancing operational efficiency. The machine operates with minimal intervention, allowing your team to focus on other critical tasks while maintaining high standards of production.

5. Durability and Reliability

Constructed with high-quality stainless steel, the MIC 12-1 is built to last and withstand the rigors of continuous operation. The robust design ensures the machine remains efficient and reliable, even in demanding production environments.

6. Ease of Maintenance

The user-friendly design of the MIC 12-1 ensures that maintenance and cleaning are straightforward. Routine maintenance can be performed quickly, minimizing downtime and ensuring smooth, uninterrupted production.

7. Precision Control Systems

The machine features sophisticated control systems that allow for fine-tuning of the filling parameters, ensuring that the beer packaging machine can adapt to different beer types, carbonation levels, and other variables with ease.

Why Choose Our Beer Filling Machines?

At Jiangsu Mic Machinery, we are proud to offer a range of high-performance beer filling machine that are built to meet the evolving needs of the beer industry. The MIC 12-1 is a perfect example of our commitment to quality, innovation, and customer satisfaction. Whether you are a small craft brewery or a large-scale beer producer, our equipment will help you streamline your operations, reduce costs, and improve product quality.

With a focus on precision engineering and advanced automation, our beer packaging machine are designed to provide maximum efficiency and reliability, ensuring that your production process runs smoothly and efficiently.

Choose Jiangsu Mic Machinery for all your beer filling and packaging needs. Our automatic beer filler are engineered to offer unmatched performance and durability, making them the ideal choice for any brewery looking to scale up production without compromising on quality.

MIC 12-1 Parameters

| Power | 1.1KW |

| Filling Heads | 12 pieces |

| Sealing Heads | 1 piece |

| Production Capacity |

1000-2000CPH based on 330ml |

| Filling Temperature | 0-4 ℃ |

| Filling Pressure | Max 5bar/0.5Mpa |

| Can Diameter Range | Ф40-90mm |

| Can Height | 92-168mm |

| Dimension |

1800*1300*1950mm |

| Weight | 1800KG |

More Model Parameters

|

Model |

MIC 12-1 |

MIC 18-1 |

MIC 18-6 |

MIC 24-6 |

MIC 32-8 |

MIC 40-10 |

MIC 4-1-1 |

MIC Manual |

|

Application |

Beer, Carbonated Beverage, Gas Drinks, Sparking Water, etc |

|||||||

|

Packing Type |

Aluminum Cans, Metal Cans, Tin Cans, Pet Cans, etc |

|||||||

|

Speed |

1000-2000CPH |

1500-2500CPH |

3000-6000CPH |

4000-8000CPH |

6000-10000CPH |

8000-15000CPH |

1000-1500CPH |

8 CPM |

|

Filling Arrange |

180ml, 250ml, 330ml, 355ml, 440ml, 500ml, 8oz, 12oz, 16oz, 1L and so on (0.1-1L) |

|||||||

|

Power |

1.1KW |

1.5KW |

2.5KW |

3.5KW |

4.2KW |

5.5KW |

2.0-3.5KW |

|

|

Size (mm) |

1800*1300*1950 |

1900*1300*1950 |

2300*1400*1900 |

2580*1700*1800 |

2800*1700*1950 |

3000*1900*2100 |

2200*1150*2050 |

575*550*480 |

|

Weight |

1800KG |

2100KG |

2500KG |

3000KG |

3800KG |

4500KG |

550KG |

15KG |

|

1 |

Name |

Brand |

|

2 |

Push Button |

Schneider France |

|

3 |

Electromagnetic Contactor |

Schneider France |

|

4 |

Relays |

Omron Japan |

|

5 |

Frequency Converter |

Siemens |

|

6 |

Air Cylinder |

AirTAC Taiwan |

|

7 |

Electromagnetic Valve |

AirTAC Taiwan |

|

8 |

PLC Control System |

Siemens |

|

9 |

Touch Screen |

Siemens |

|

10 |

Photoelectric Switch |

Autonics |

|

11 |

Proximity Switch |

Autonics |

|

12 |

Reducer |

Zhejiang Duoli China |

|

13 |

Sealing Motor |

Zhejiang Duoli China |

|

14 |

Barometer |

AirTAC Taiwan |

|

15 |

Bearing |

Harbin China |