MIC 18-1 Automatic Beer Filler (1500-2500CPH)

Introduction to the MIC 18-1 Automatic Beer Filler: Advanced, High-Capacity Filling Solution

Jiangsu Mic Machinery is a global leader in providing advanced beverage filling and packaging equipment. With a commitment to innovation and quality, we specialize in the design and manufacturing of beer filling equipment that enhances operational efficiency and product consistency. The MIC 18-1 automatic beer filler (1500-2500CPH) represents the pinnacle of our engineering expertise, offering high-speed, precise filling for breweries looking to scale up production without compromising on quality.

|

|

Inline Can Rinser / Can Washing Machine |

|

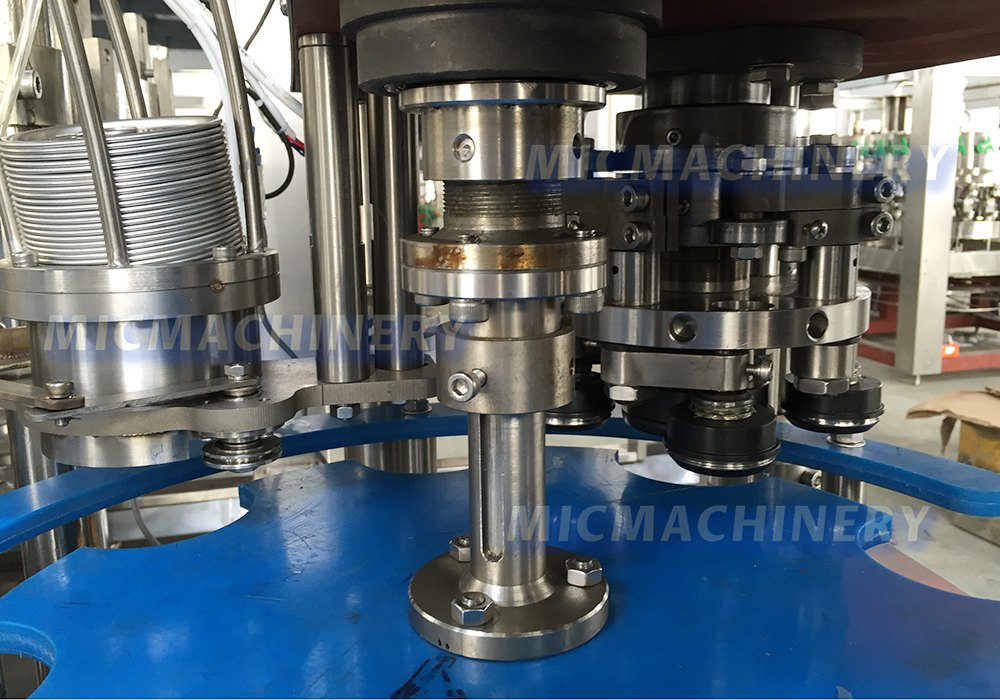

Isobaric Pressure/ Counter Pressure Filling System

The isobaric pressure filling system is designed for filling carbonated beverages like beer without excessive foaming or loss of carbonation. It works by equalizing the pressure between the product tank and the empty can or bottle before filling begins. This controlled environment ensures accurate filling levels, preserves carbonation, and minimizes oxygen exposure, which helps maintain product freshness and quality. |

|

|

Foaming Device Before Seaming For Craft Beer

The foaming device before seaming is used to inject a small amount of hot water or CO₂ into the filled can just before sealing. This creates a layer of foam that pushes out oxygen from the headspace, reducing oxidation and extending the shelf life of craft beer. It helps preserve flavor, aroma, and carbonation by maintaining a low-oxygen environment inside the can. |

|

Aluminum Lid Seaming System

The aluminum lid seaming system is responsible for securely sealing cans after filling. It uses a rotating seaming head to crimp the aluminum lid tightly onto the can body, forming a leak-proof and airtight seal. This system ensures high-speed, consistent sealing performance, which is critical for maintaining carbonation, freshness, and preventing contamination in canned beverages. |

|

Key Features of the MIC 18-1 Automatic Beer Filler

The MIC 18-1 automatic beer filler is a high-capacity solution for breweries that demand both speed and precision. Capable of filling between 1500 and 2500 bottles per hour, this machine is designed to meet the rigorous demands of high-volume production while ensuring the highest levels of quality and operational efficiency.

1. High-Speed Filling: With a filling capacity of 1500-2500 bottles per hour, the beer filling machine significantly increases production output. This makes it ideal for medium to large-scale breweries looking to boost efficiency and meet growing market demand without sacrificing the integrity of the product.

2. Precision Filling Technology: The beer filling equipment uses an advanced gravity filling system to ensure accurate, consistent fills. This technology minimizes spillage, waste, and foam, ensuring that each bottle is filled to the exact level while preserving the beer's quality and carbonation.

3. Fully Automated Operation: As an automatic beer filler, the MIC 18-1 automates the entire filling process, from bottle handling to filling and capping. The fully automated system reduces the need for manual labor, improving efficiency and reducing the risk of human error. The intuitive control panel allows operators to easily adjust settings and monitor the machine's performance.

4. Durable Construction: Constructed from high-quality stainless steel, the MIC 18-1 is built to withstand continuous operation and maintain its performance over time. Its robust design ensures long-term reliability, reducing the likelihood of breakdowns and costly repairs.

5. Advanced Control Systems: The beer filling machine is equipped with a sophisticated control system that allows for real-time monitoring of the filling process. This ensures that the machine operates at optimal efficiency and can be easily adjusted to accommodate different beer types and bottle sizes.

6. Flexible Compatibility: The MIC 18-1 is compatible with a variety of bottle types and sizes, offering flexibility to breweries with diverse packaging requirements. This adaptability ensures that the beer filling equipment can be seamlessly integrated into existing production lines, regardless of the specific needs of the brewery.

7. Ease of Maintenance: Routine maintenance is made easier with the machine’s user-friendly design. The MIC 18-1 features easy access to key components, reducing downtime for cleaning and servicing. The machine’s modular design also simplifies troubleshooting, ensuring minimal disruption to production schedules.

8. Environmental Efficiency: The automatic beer filler is designed with sustainability in mind. Its efficient filling process reduces beer waste, helping breweries reduce their environmental impact. The precise filling system ensures that each bottle is filled with the exact amount of beer needed, minimizing excess and waste.

Why Choose the MIC 18-1 Automatic Beer Filler?

At Jiangsu Mic Machinery, we understand the challenges breweries face when scaling up production while maintaining product quality. The MIC 18-1 automatic beer filler is the ideal solution for breweries that require high-speed, high-quality filling equipment. Whether you are filling bottles for local markets or expanding your distribution, this beer filling machine delivers the precision, speed, and reliability needed to keep your production lines running smoothly.

With its advanced filling technology, automated operation, and robust construction, the MIC 18-1 offers exceptional value for breweries seeking to improve their operational efficiency and scale production. Choose Jiangsu Mic Machinery for all your beer filling equipment needs and experience the difference in quality, performance, and reliability.

MIC 18-1 Parameters

| Power | 1.5KW |

| Filling Heads | 18 pieces |

| Sealing Heads | 1 piece |

| Production Capacity |

1000-2500CPH based on 330ml |

| Filling Temperature | 0-4 ℃ |

| Filling Pressure | Max 5bar/0.5Mpa |

| Can Diameter Range | Ф40-90mm |

| Can Height | 92-168mm |

| Dimension |

1900*1300*1950mm |

| Weight | 2100KG |

More Model Parameters

|

Model |

MIC 12-1 |

MIC 18-1 |

MIC 18-6 |

MIC 24-6 |

MIC 32-8 |

MIC 40-10 |

MIC 4-1-1 |

MIC Manual |

|

Application |

Beer, Carbonated Beverage, Gas Drinks, Sparking Water, etc |

|||||||

|

Packing Type |

Aluminum Cans, Metal Cans, Tin Cans, Pet Cans, etc |

|||||||

|

Speed |

1000-2000CPH |

1500-2500CPH |

3000-6000CPH |

4000-8000CPH |

6000-10000CPH |

8000-15000CPH |

1000-1500CPH |

8 CPM |

|

Filling Arrange |

180ml, 250ml, 330ml, 355ml, 440ml, 500ml, 8oz, 12oz, 16oz, 1L and so on (0.1-1L) |

|||||||

|

Power |

1.1KW |

1.5KW |

2.5KW |

3.5KW |

4.2KW |

5.5KW |

2.0-3.5KW |

|

|

Size (mm) |

1800*1300*1950 |

1900*1300*1950 |

2300*1400*1900 |

2580*1700*1800 |

2800*1700*1950 |

3000*1900*2100 |

2200*1150*2050 |

575*550*480 |

|

Weight |

1800KG |

2100KG |

2500KG |

3000KG |

3800KG |

4500KG |

550KG |

15KG |

|

Name |

Brand |

|

Buttons |

Schneider (France) |

|

Touch screen |

Siemens (Optional) |

|

AC Contactor |

Schneider (France) |

|

PLC |

Mitsubishi (Japan) / Siemens (Optional) |

|

Frequency changer |

Schneider (France) |

|

Air cylinder |

AirTAC (China) / FESTO (Optional) |

|

Solenoid valve |

AirTAC (China) / FESTO (Optional) |

|

Relay |

Omron (Japan) / Schneider (France) |

|

photoelectric sensor |

Autonics (Korea) / Omron (Optional) |

|

Proximity switch |

Autonics / Omron (Optional) |