MIC 12-1 Beverage Canning Machine (1000-2000CPH)

Introduction to the MIC 12-1 Beverage Canning Machine (1000-2000 CPH)

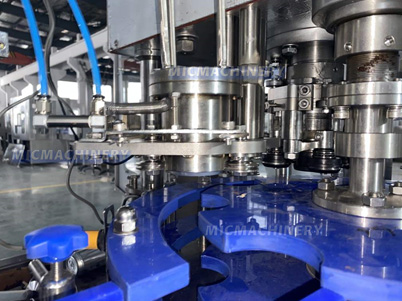

At Jiangsu Mic Machinery, we specialize in providing cutting-edge solutions for beverage production lines. Our MIC 12-1 beverage canning machine offers an efficient and reliable way to fill and seal cans for a wide range of beverages, from soft drinks to carbonated beverages. Designed for medium-scale production with a capacity range of 1000-2000 cans per hour (CPH), this machine is ideal for companies seeking a balance between high performance and cost-effectiveness. With a focus on quality, automation, and ease of use, our beverage can filling machine ensures that your beverage production is streamlined and meets the highest standards.

|

|

|

|

Isobaric pressure / counter pressure filling system

The 12-1 isobaric counter pressure filling system is specifically designed for aluminum cans, ensuring a smooth filling process without foaming—provided the beer temperature remains below 40°F. This system maintains a standard 1.27 cm headspace, complying with can manufacturers’ requirements to accommodate product expansion during distribution. Our filling method minimizes dissolved oxygen (DO) levels in the can, preserving product quality. Built with a high-grade 304 food-grade stainless steel tank and precision buffing, the unit ensures hygiene and durability. A CIP connection can be added upon request to support automated cleaning protocols. |

|

Working Principle of the Beverage Canning Machine

The MIC 12-1 beverage canning machine utilizes advanced filling technology to automate the canning process efficiently. Here's a breakdown of how it works:

1)Canning Process

The machine operates using a vacuum-assisted filling system, which ensures that each can is filled precisely to the desired volume. This method prevents overfill and minimizes product loss, ensuring a high level of accuracy and reducing waste.

2)Sealing and Capping

After filling, the cans move to the capping station where the system applies lids with a secure seal. The beverage canning equipment is designed for consistent and reliable sealing to ensure that the cans are properly closed, preventing leakage and preserving beverage freshness.

3)Automation

While some manual intervention is required, the majority of the canning process, including filling, sealing, and labeling, is automated. The semi-automated design helps streamline the production process, improving speed and minimizing errors. The control panel allows for easy monitoring and adjustment of key parameters, such as filling volume and speed, ensuring smooth operations.

4)Control and Monitoring

The user-friendly interface allows operators to control the machine's settings and monitor the process in real time. This enables quick adjustments to production rates or product specifications, enhancing flexibility without compromising on performance.

Function of the Beverage Canning Machine

The MIC 12-1 beverage canning machine is equipped with multiple functions that optimize your beverage production line:

Accurate Filling:The beverage can filling machine is designed for precise filling, ensuring that each can is filled to the correct level. This precision reduces the risk of spillage, minimizes waste, and guarantees consistent product quality.

Seamless Capping:The machine's automatic capping function securely seals the cans, ensuring that they are tightly closed and preventing leaks. This step is critical to maintaining the quality and shelf life of the product.

Flexible for Various Beverage Types:The beverage canning equipment is suitable for a variety of beverage types, including carbonated drinks, juices, and energy drinks. The system is easily adaptable, allowing manufacturers to switch between different products with minimal downtime.

Enhanced Throughput:With a filling capacity of 1000-2000 cans per hour, the machine strikes a perfect balance between speed and efficiency. It is an excellent choice for companies with mid-range production volumes, allowing them to meet market demands without investing in larger, more expensive systems.

Simple Operation:The system is designed to be easy to operate, with intuitive controls and minimal training required for staff. The automation of the canning process reduces the need for manual labor, lowering operational costs and improving productivity.

Advantages of the Beverage Canning Machine

The MIC 12-1 beverage canning machine offers several key advantages, making it an essential tool for modern beverage production lines:

1、Cost-Effective Solution

The semi-automatic nature of the machine provides significant savings compared to fully automated systems, offering an ideal solution for medium-sized beverage manufacturers. With its balanced cost and performance, it helps companies reduce production expenses without compromising on quality.

2、High Efficiency and Speed

The machine’s impressive filling speed, capable of handling between 1000 to 2000 cans per hour, makes it suitable for mid-scale operations. Its efficiency in filling and sealing also helps maximize production output, ensuring that manufacturers can meet high demand with minimal downtime.

3、Enhanced Product Quality

The precision filling and secure capping mechanisms help preserve the beverage's quality. By ensuring that the cans are filled to the exact volume and sealed tightly, the machine helps maintain the freshness and shelf life of the product, ultimately increasing customer satisfaction.

4、Durability and Reliability

Built with high-quality materials, the MIC 12-1 beverage canning machine is designed for durability. Its robust construction allows it to withstand the demands of continuous operation, ensuring long-term reliability and minimizing the need for frequent repairs.

5、Ease of Maintenance

The machine’s design simplifies maintenance and cleaning procedures. With easy access to key components, operators can perform routine maintenance quickly, reducing downtime and keeping the production line running smoothly.

6、Versatility

The beverage canning equipment is adaptable to various can sizes and types, making it a versatile solution for different production needs. It can handle both carbonated and non-carbonated beverages, providing flexibility for manufacturers that produce multiple beverage lines.

7、Scalability

As your production needs grow, the MIC 12-1 beverage canning machine can be integrated into larger systems or scaled up with additional units. This makes it an excellent long-term investment for growing businesses.

Conclusion

The MIC 12-1 beverage canning machine from Jiangsu Mic Machinery provides a high-quality, cost-effective solution for beverage manufacturers looking to optimize their canning processes. With precise filling, reliable sealing, and a user-friendly interface, this machine is perfect for mid-sized production lines that demand efficiency and flexibility. Whether you are bottling soft drinks, juices, or carbonated beverages, the MIC 12-1 beverage canning equipment is designed to meet your needs with exceptional performance and reliability.

At Jiangsu Mic Machinery, we are committed to providing industry-leading solutions for beverage production, helping you scale your operations and meet market demands efficiently and cost-effectively.

Mic 12-1 Parameters

| Power | 1.1Kw |

| Filling heads | 12piece |

| Sealing heads | 1piece |

| Production capacity |

1000-2000CPH based on 330ml |

| Filling temperature | 0-4 ℃ |

| Filling pressure | Max 5bar/0.5Mpa |

| Can diameter range | Ф40-90MM |

| Can height | 92-168MM |

| Dimension |

1800*1300*1950mm |

| Weight | 1800Kg |

|

1 |

Name |

Brand |

|

2 |

Push Button |

Schneider France |

|

3 |

Electromagnetic Contactor |

Schneider France |

|

4 |

Relays |

Omron Japan |

|

5 |

Frequency Converter |

Siemens |

|

6 |

Air Cylinder |

AirTAC Taiwan |

|

7 |

Electromagnetic Valve |

AirTAC Taiwan |

|

8 |

PLC Control System |

Siemens |

|

9 |

Touch Screen |

Siemens |

|

10 |

Photoelectric Switch |

Autonics |

|

11 |

Proximity Switch |

Autonics |

|

12 |

Reducer |

Zhejiang Duoli China |

|

13 |

Sealing Motor |

Zhejiang Duoli China |

|

14 |

Barometer |

AirTAC Taiwan |

|

15 |

Bearing |

Harbin China |