MIC 12-1 Fully Automatic Beverage Can Filling Machine (1000-2000CPH)

Introduction to the MIC 12-1 Fully Automatic Beverage Can Filling Machine

At Jiangsu Mic Machinery, we specialize in providing advanced solutions for the beverage industry. Our MIC 12-1 fully automatic beverage can filling machine is designed to streamline your production process, offering high efficiency, reliability, and superior product quality. Whether you're filling soft drinks, carbonated beverages, or juices, our beverage canning equipment ensures precise filling, capping, and sealing, meeting the demanding requirements of modern beverage production lines.

|

|

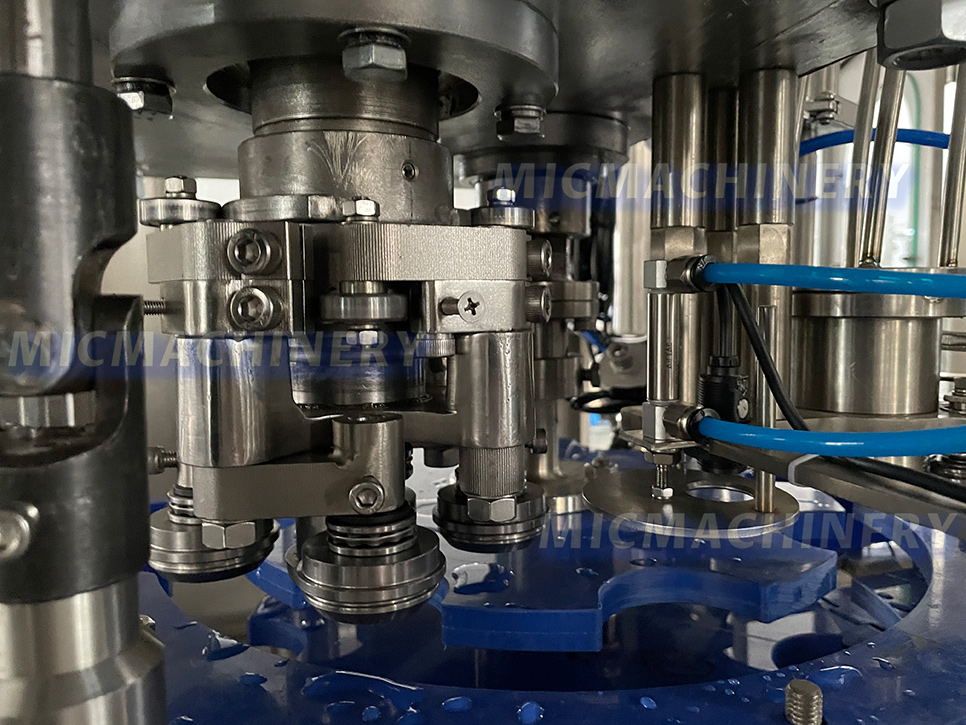

Aluminum can seaming system The aluminum can seaming system ensures airtight, secure seals for beverage and food cans. Designed for precision and reliability, it enhances product freshness and prevents leaks during storage and transport. |

|

Gravity liquid filling system The gravity liquid filling system offers a reliable, efficient solution for accurately filling beverages and liquids. Ideal for various industries, it ensures smooth operation, precision, and minimal product wastage.

|

|

|

|

Liquid nitrogen dispenser The liquid nitrogen dispenser provides precise nitrogen dosing for food and beverage packaging. It enhances product shelf life, prevents oxidation, and ensures reliable, efficient packaging operations. |

Working Principle of the Beverage Canning Machine

The MIC 12-1 beverage can filling machine operates using an advanced fully automatic system designed to optimize every stage of the canning process:

1)Filling Process

The canning beverage machine uses a vacuum-assisted filling system that ensures each can is accurately filled to the desired level. This system prevents overfilling and minimizes product waste, contributing to cost savings while ensuring each can is filled with the correct amount of beverage.

2)Sealing and Capping

Once the cans are filled, they are transported to the capping station where the machine automatically applies secure lids to each can. The sealing process is essential for maintaining beverage freshness and preventing leakage, and the beverage canning equipment ensures a tight seal on every can for maximum quality.

3)Automated Control System

The MIC 12-1 features a fully automated control system that allows for seamless operation with minimal human intervention. The system is designed to adjust parameters such as filling volume and speed, allowing operators to maintain full control over the production process. The intuitive control panel offers real-time monitoring and adjustment capabilities, ensuring smooth operations.

4)Integration with Production Line

Designed to work seamlessly within a fully automated production line, the MIC 12-1 integrates easily with other equipment such as labelers, conveyors, and packaging machines. This integration ensures a smooth and efficient workflow, reducing production bottlenecks and improving throughput.

Advantages of the Beverage Canning Machine

The MIC 12-1 beverage canning machine provides several key advantages for beverage manufacturers, making it an essential piece of equipment for modern production lines:

1、High Efficiency and Speed

The MIC 12-1 offers an impressive filling speed, enabling high-volume production with minimal downtime. Its fully automated design increases throughput, allowing manufacturers to meet market demands with greater efficiency. With the ability to fill and seal cans quickly, this machine can handle large-scale production without sacrificing quality.

2、Precision Filling

The beverage can filling machine guarantees precise filling of each can, which helps to maintain consistent product quality. The advanced filling system reduces the risk of overfilling and ensures that the correct amount of beverage is dispensed into each can, minimizing waste and improving cost-effectiveness.

3、Reliable Sealing

The beverage canning equipment provides reliable sealing of cans, ensuring that each can is securely closed to prevent leakage and preserve product freshness. The sealing mechanism is designed to provide a tight, long-lasting seal that maintains the integrity of the beverage, enhancing its shelf life and ensuring high-quality products for your customers.

4、User-Friendly Operation

The MIC 12-1 is equipped with an intuitive control panel, making it easy to operate and monitor. Even with fully automated functions, operators can easily make adjustments to filling volumes, speeds, and other parameters. This user-friendly interface reduces the learning curve and increases operational efficiency.

5、Durable and Low Maintenance

Built with high-quality materials, the MIC 12-1 is durable and designed for long-term use. Its robust construction can withstand the demands of continuous operation, ensuring reliable performance over time. The machine is also designed for easy maintenance, with accessible parts that simplify cleaning and servicing.

6、Versatile Beverage Compatibility

The canning beverage machine is highly versatile, capable of filling a wide range of beverages, including carbonated drinks, soft drinks, juices, and more. The system can be easily adapted for different beverage types, making it ideal for companies that produce multiple product lines. This flexibility reduces the need for specialized equipment, saving space and operational costs.

7、Cost-Effective Solution

The fully automatic nature of the MIC 12-1 beverage can filling machine reduces labor costs, improving overall operational efficiency. By automating the canning process, manufacturers can increase production capacity while reducing human error, helping to minimize production delays and maximize profitability.

8、Scalability

As your production needs grow, the MIC 12-1 can be integrated into larger systems or scaled up with additional units. This scalability makes the machine a future-proof investment for growing beverage manufacturers, ensuring long-term support as production demands increase.

Conclusion

The MIC 12-1 fully automatic beverage can filling machine is an essential tool for modern beverage manufacturing, offering unmatched efficiency, precision, and reliability. Whether you're producing carbonated beverages, soft drinks, or juices, this beverage canning equipment provides a cost-effective, high-performance solution for your production line. With its automation, ease of use, and reliable performance, the MIC 12-1 enhances your beverage canning process, ensuring that your products meet the highest standards of quality.

At Jiangsu Mic Machinery, we are committed to providing innovative, durable, and efficient solutions for the beverage industry. Our machines are designed to help you optimize production, reduce operational costs, and improve the quality of your products. Contact us today to learn more about how our beverage canning machine can enhance your production process.

Mic 12-1 Parameters

| Power | 1.1Kw |

| Filling heads | 12piece |

| Sealing heads | 1piece |

| Production capacity |

1000-2000CPH based on 330ml |

| Filling temperature | 0-4 ℃ |

|

Can diameter range |

Ф40-90MM |

|

Can height |

92-168MM |

|

Dimension |

1800*1300*1950mm |

|

Weight |

1800Kg |

|

1 |

Name |

Brand |

|

2 |

Push Button |

Schneider France |

|

3 |

Electromagnetic Contactor |

Schneider France |

|

4 |

Relays |

Omron Japan |

|

5 |

Frequency Converter |

Siemens |

|

6 |

Air Cylinder |

AirTAC Taiwan |

|

7 |

Electromagnetic Valve |

AirTAC Taiwan |

|

8 |

PLC Control System |

Siemens |

|

9 |

Touch Screen |

Siemens |

|

10 |

Photoelectric Switch |

Autonics |

|

11 |

Proximity Switch |

Autonics |

|

12 |

Reducer |

Zhejiang Duoli China |

|

13 |

Sealing Motor |

Zhejiang Duoli China |

|

14 |

Barometer |

AirTAC Taiwan |

|

15 |

Bearing |

Harbin China |