MIC 12-1 Canning Machine for Drinks (1000-2000CPH)

Introducing the MIC 12-1 Canning Machine for Drinks (1000-2000CPH)

At Jiangsu Mic Machinery, we are committed to delivering state-of-the-art solutions for the beverage industry. Our MIC 12-1 canning machine for drinks is engineered to provide unmatched efficiency, precision, and reliability. Designed for medium to high-volume production lines, this machine is the perfect solution for businesses seeking to optimize their canning operations. With a capacity range of 1000 to 2000 cans per hour (CPH), it is an ideal choice for those looking to scale production without compromising on quality or speed.

|

Isobaric pressure / counter pressure filling system

The 12-1 isobaric counter pressure filling system is specifically designed for aluminum cans, ensuring a smooth filling process without foaming—provided the beer temperature remains below 40°F. This system maintains a standard 1.27 cm headspace, complying with can manufacturers’ requirements to accommodate product expansion during distribution. Our filling method minimizes dissolved oxygen (DO) levels in the can, preserving product quality. Built with a high-grade 304 food-grade stainless steel tank and precision buffing, the unit ensures hygiene and durability. A CIP connection can be added upon request to support automated cleaning protocols. |

|

|

|

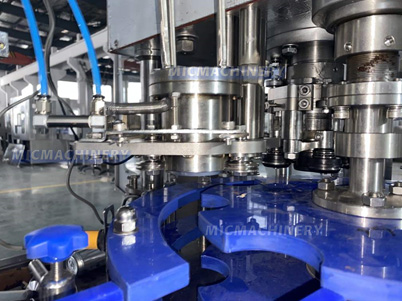

Aluminum lid seaming system |

Key Features of the MIC 12-1 Canning Machine for Drinks

1、High-Speed and High-Capacity Operation

The MIC 12-1 is capable of filling between 1000 to 2000 cans per hour, making it an excellent choice for medium and large-scale beverage producers. Whether you’re working with carbonated soft drinks, energy drinks, juices, or flavored water, this drink canning machine can handle a variety of beverages while maintaining a steady and high throughput. Its robust design ensures consistent performance, even in the most demanding production environments.

2、Advanced Filling Technology for Precision and Accuracy

One of the standout features of the MIC 12-1 drinks canning machine is its advanced filling technology. This machine utilizes an isobaric pressure filling system, ensuring that cans are filled with exceptional accuracy. The isobaric system maintains constant pressure, which prevents the loss of carbonation in carbonated beverages and ensures a perfect fill every time. This technology minimizes the risk of overfilling or underfilling, delivering uniform volume across all cans.

3、Versatile Beverage Handling

The MIC 12-1 canning machine for drinks is designed with versatility in mind. Whether you are producing carbonated beverages or non-carbonated drinks, the MIC 12-1 can adapt to various types of beverages with minimal adjustments. This flexibility allows you to streamline your production process and reduce the need for different machines for different products. With an easy-to-change setup, this machine can accommodate different can sizes, making it an invaluable addition to any production line.

4、Hygienic Design for Optimal Food Safety

Hygiene is a top priority in beverage packaging, and the MIC 12-1 is built to meet the highest standards of sanitation. The machine is constructed with corrosion-resistant materials, making it easy to clean and maintain. Its smooth surfaces and well-designed components reduce the buildup of residue, ensuring a clean and safe environment for beverage production. The control panel and machine components are designed for quick and efficient cleaning between production runs, promoting food safety while minimizing downtime.

5、User-Friendly and Intuitive Controls

The MIC 12-1 drink canning machine features a user-friendly interface that makes operation simple and intuitive. The advanced control panel is easy to navigate, offering real-time monitoring and diagnostics to ensure that the machine runs efficiently at all times. With touchscreen functionality, operators can quickly adjust settings and monitor production parameters, making it easy to optimize the filling process for different beverages. The system also includes automated features to reduce human error and improve consistency.

6、Durability and Long-Term Reliability

Built with durability in mind, the MIC 12-1 is designed to withstand the rigors of continuous high-speed production. Its components are made from high-quality materials, ensuring long-lasting performance even in demanding environments. The machine’s robust construction is designed to minimize downtime and reduce the need for frequent repairs, ensuring that your production line operates smoothly year after year.

7、Energy-Efficient Operation

At Jiangsu Mic Machinery, we understand the importance of energy efficiency in modern manufacturing processes. The MIC 12-1 is engineered to minimize energy consumption without sacrificing performance. Its advanced systems ensure that energy is used optimally throughout the production process, helping reduce operational costs and contributing to more sustainable production practices.

8、Customization Options for Unique Production Needs

We recognize that each production line has unique requirements. That’s why the MIC 12-1 canning machine for drinks offers various customization options. Whether you need to adjust the machine’s speed, integrate additional features for specific beverage types, or modify the setup for different can sizes, Jiangsu Mic Machinery can tailor the MIC 12-1 to suit your specific needs. This flexibility ensures that you get the most out of your investment.

Why Choose Jiangsu Mic Machinery?

Jiangsu Mic Machinery is a leader in the beverage canning and packaging equipment industry, renowned for our commitment to quality, innovation, and customer satisfaction. Our products are designed with the needs of our clients in mind, and the MIC 12-1 canning machine for drinks is no exception. From its high-speed filling capabilities to its advanced features and reliability, this machine provides exceptional value for beverage manufacturers seeking to improve their production efficiency.

With years of experience in the industry, our team of engineers and support professionals are always available to assist you throughout the lifecycle of your equipment. From installation to training, maintenance, and upgrades, we provide comprehensive after-sales support to ensure your production line operates at peak performance.

The MIC 12-1—Your Solution for Efficient and Reliable Beverage Canning

If you're looking for a reliable, efficient, and high-performance drink canning machine, the MIC 12-1 is the perfect solution for your production needs. Whether you're scaling up your production line or looking to optimize your existing operations, Jiangsu Mic Machinery offers the expertise and technology needed to help you succeed.

Contact us today for more information about the MIC 12-1 or to request a quote. Let us partner with you to streamline your beverage canning process and elevate your production capabilities.

Mic 12-1 Parameters

| Power | 1.1Kw |

| Filling heads | 12piece |

| Sealing heads | 1piece |

| Production capacity |

1000-2000CPH based on 330ml |

| Filling temperature | 0-4 ℃ |

| Filling pressure | Max 5bar/0.5Mpa |

| Can diameter range | Ф40-90MM |

| Can height | 92-168MM |

| Dimension |

1800*1300*1950mm |

| Weight | 1800Kg |

More Model And Speed Click

| Model | MIC 12-1 | MIC 18-1 | MIC 18-6 | MIC 24-6 | MIC 32-8 |

| Application | Beer, Carbonated Beverage, Gas Drinks, Cold Coffee, Sparking Water, Cider, Soda Water, Herbal Tea, Non-Carbonated Drinks And So On | ||||

| Packing Type | Aluminum Cans, Metal Cans, Tin Cans, Pet Cans Etc | ||||

| Speed | 1000-2000CPH | 1000-2500CPH | 3000-6000CPH | 4000-8000CPH | 6000-10000CPH |

| Filling Arrange | 180ml, 250ml, 330ml, 355ml, 440ml, 500ml, 8oz, 12oz, 16oz, 1L and so on (0.1-1L) | ||||

| Power | 1.1kw | 1.5kw | 2.5kw | 3.5kw | 4.2kw |

| Size | 1.8*1.3*1.95 (M) | 1.9*1.3*1.95(M) | 2.3*1.4*1.9(M) | 2.58*1.7*1.8(M) | 2.8*1.7*1.95(M) |

| Weight | 1800KG | 2100KG | 2500KG | 3000KG | 3800(KG) |

|

1 |

Name |

Brand |

|

2 |

Push Button |

Schneider France |

|

3 |

Electromagnetic Contactor |

Schneider France |

|

4 |

Relays |

Omron Japan |

|

5 |

Frequency Converter |

Siemens |

|

6 |

Air Cylinder |

AirTAC Taiwan |

|

7 |

Electromagnetic Valve |

AirTAC Taiwan |

|

8 |

PLC Control System |

Siemens |

|

9 |

Touch Screen |

Siemens |

|

10 |

Photoelectric Switch |

Autonics |

|

11 |

Proximity Switch |

Autonics |

|

12 |

Reducer |

Zhejiang Duoli China |

|

13 |

Sealing Motor |

Zhejiang Duoli China |

|

14 |

Barometer |

AirTAC Taiwan |

|

15 |

Bearing |

Harbin China |