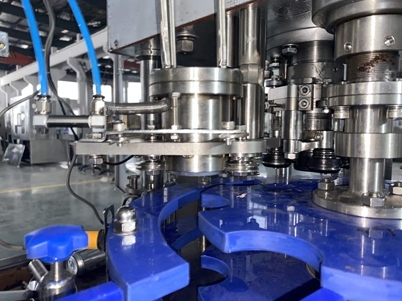

MIC 12-1 Carbonated Drink Filling Machine (1000-2000CPH)

Machine is Suitable For

The MIC 12-1 soda canning machine is an ideal solution for beverage manufacturers that specialize in carbonated drinks. With a production capacity of 1000 to 2000 cans per hour (CPH), this machine is perfectly suited for medium to large-scale production lines in factories or bottling plants. Whether you are producing soda, sparkling water, or other carbonated beverages, this machine is designed to efficiently handle high volumes of liquid packaging while maintaining product quality. Its versatile capabilities make it a great choice for businesses looking to expand their production or optimize existing lines with reliable carbonated beverage fill equipment.

|

|

|

|

Isobaric pressure / counter pressure filling system

The 12-1 isobaric counter pressure filling system is specifically designed for aluminum cans, ensuring a smooth filling process without foaming—provided the beer temperature remains below 40°F. This system maintains a standard 1.27 cm headspace, complying with can manufacturers’ requirements to accommodate product expansion during distribution. Our filling method minimizes dissolved oxygen (DO) levels in the can, preserving product quality. Built with a high-grade 304 food-grade stainless steel tank and precision buffing, the unit ensures hygiene and durability. A CIP connection can be added upon request to support automated cleaning protocols. |

|

Machine Features

This carbonated drink filling machine is equipped with advanced technology that ensures fast and precise filling. It features a high-speed filling system that accurately fills cans with carbonated drinks while preserving the effervescence of the beverage. The machine’s integrated carbonated drink handling system ensures that the pressure is maintained during the filling process, preventing the loss of carbonation and keeping the product in optimal condition.

The carbonated drink filling equipment is designed with ease of operation in mind. It comes with a user-friendly control panel that allows operators to set and adjust parameters such as filling speed and can size with minimal effort. This flexibility makes it ideal for manufacturers producing a variety of carbonated beverages in different packaging formats.

Another key feature is its advanced sealing mechanism, which ensures secure, airtight can closures to maintain the integrity of the product. The machine is also designed with quick-change parts, enabling operators to switch between different can sizes with minimal downtime, ensuring continuous production.

Machine Introduction

The MIC 12-1 soda canning machine is designed for high-performance, durability, and ease of use. As part of our commitment to quality, this carbonated beverage fill equipment is built with premium materials to withstand the demands of high-volume production. Its robust construction and reliable operation make it a long-term investment for any beverage manufacturing company.

Equipped with the latest automation features, this carbonated drink filling machine minimizes human intervention and reduces the likelihood of errors, thus improving operational efficiency. The machine also has an integrated cleaning system that ensures hygienic filling processes, reducing downtime for maintenance and cleaning tasks. With a production capacity of 1000-2000 cans per hour, it significantly boosts throughput while maintaining the highest standards of beverage quality.

Designed with energy efficiency in mind, the MIC 12-1 soda canning machine also helps reduce operational costs while maintaining optimal performance. Its compact design allows it to fit seamlessly into existing production lines, providing a flexible solution for growing businesses looking to scale their production capacity.

Mic 12-1 Parameters

| Power | 1.1Kw |

| Filling heads | 12piece |

| Sealing heads | 1piece |

| Production capacity |

1000-2000CPH based on 330ml |

| Filling temperature | 0-4 ℃ |

| Filling pressure | Max 5bar/0.5Mpa |

| Can diameter range | Ф40-90MM |

| Can height | 92-168MM |

| Dimension |

1800*1300*1950mm |

| Weight | 1800Kg |

|

1 |

Name |

Brand |

|

2 |

Push Button |

Schneider France |

|

3 |

Electromagnetic Contactor |

Schneider France |

|

4 |

Relays |

Omron Japan |

|

5 |

Frequency Converter |

Siemens |

|

6 |

Air Cylinder |

AirTAC Taiwan |

|

7 |

Electromagnetic Valve |

AirTAC Taiwan |

|

8 |

PLC Control System |

Siemens |

|

9 |

Touch Screen |

Siemens |

|

10 |

Photoelectric Switch |

Autonics |

|

11 |

Proximity Switch |

Autonics |

|

12 |

Reducer |

Zhejiang Duoli China |

|

13 |

Sealing Motor |

Zhejiang Duoli China |

|

14 |

Barometer |

AirTAC Taiwan |

|

15 |

Bearing |

Harbin China |