The 18-1 isobaric counter pressure filling system from “MIC” ensures a smooth, foam-free filling process—provided the beer remains below 40°F. Designed to maintain a standard 1.27 cm headspace as required by can manufacturers, it effectively accounts for product expansion and temperature fluctuations during transit. This system minimizes dissolved oxygen (DO) levels in the can, preserving beverage quality. Built with food-grade 304 stainless steel and finished with high-precision polishing, it offers superior hygiene and durability. A CIP connector can also be integrated based on customer needs, ensuring convenient and thorough internal cleaning.

MIC 18-1 Carbonated Beverage Fill Equipment (1500-2500CPH)

Machine Is Suitable For

The MIC 18-1 is a state-of-the-art carbonated beverage fill equipment designed to meet the needs of modern beverage manufacturers. This machine is suitable for filling carbonated drinks such as sodas, sparkling waters, and other fizzy beverages into bottles or cans. Whether you’re producing on a small or large scale, the MIC 18-1 is engineered to deliver exceptional performance, efficiency, and reliability across various production environments.

With its versatile design, this carbonated drink filling machine can accommodate multiple container sizes and shapes, making it ideal for companies that prioritize flexibility in their operations. From PET bottles to aluminum cans, the MIC 18-1 ensures that every container is filled with precision and retains the carbonation required for a premium-quality beverage.

|

|

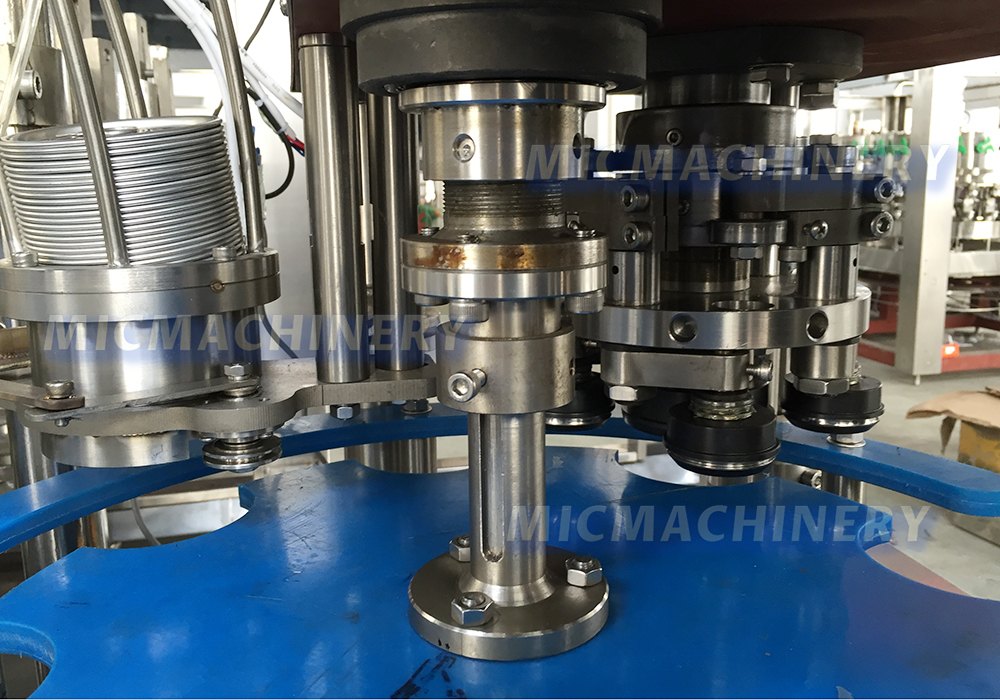

Isobaric pressure / counter pressure filling system

|

|

Can filling seaming machine lid feed system

The lid feed system in a can filling seaming machine is responsible for automatically supplying lids to the cans during the sealing process. It ensures a smooth and continuous flo

w of lids, preventing delays and maintaining production efficiency. The system typically uses a conveyor or vibratory feeder to align and position lids correctly before they are placed on the filled cans. This automated process reduces the risk of contamination, improves the consistency of the seal, and speeds up the overall canning operation. The lid feed system is essential for ensuring that each can is securely sealed, maintaining product quality and preventing leakage. |

|

Working Principle of the Carbonated Filling Machine

The MIC 18-1 carbonated filling machine integrates advanced technology to achieve precise filling and capping in one seamless operation. The process begins with automatic container rinsing to ensure that all bottles or cans are clean before the filling stage. Once cleaned, the containers move to the filling station, where the carbonated beverage is dispensed under controlled pressure.

This machine is equipped with advanced pressure and level control systems, ensuring the carbonated beverage fill equipment maintains the desired carbonation levels while filling. Sensors and a PLC (Programmable Logic Controller) ensure that the filling process is consistent, precise, and highly efficient. After filling, the machine automatically caps the containers, sealing in the carbonation and maintaining product quality during transportation and storage.

Additionally, the MIC 18-1 includes features like automatic bottle detection and adjustable filling settings, allowing manufacturers to customize the filling volume to match specific product requirements.

Advantages of the Carbonated Filling Machine

The MIC 18-1 offers a range of advantages that make it an excellent choice for beverage manufacturers:

1、High Efficiency

This carbonated drink filling machine is designed to handle high-speed production lines, filling up to 10,000 containers per hour, depending on the container size.

2、Consistency and Precision

The machine uses advanced filling technology to ensure each bottle or can is filled to the exact specified level, preserving carbonation and delivering consistent quality.

3、User-Friendly Design

The intuitive control panel and automated features make the MIC 18-1 easy to operate and monitor, reducing the need for extensive operator training.

4、Durable Construction

Built with high-grade stainless steel and food-grade components, this carbonated filling machine is durable, corrosion-resistant, and compliant with industry hygiene standards.

5、Energy Efficiency

The MIC 18-1 is engineered to optimize energy use while maintaining high levels of performance, making it a cost-effective and environmentally friendly solution.

6、Flexibility

With adjustable settings and compatibility with various container types, this machine is perfect for businesses that produce a wide range of carbonated beverages.

7、Compact and Space-Saving Design

The MIC 18-1 is designed to integrate seamlessly into your production line without taking up excessive space, making it suitable for facilities of all sizes.

In conclusion, the MIC 18-1 carbonated beverage fill equipment is a powerful, efficient, and versatile machine tailored to meet the rigorous demands of the beverage industry. By choosing the MIC 18-1, manufacturers can ensure superior product quality, operational efficiency, and long-term reliability, all while maintaining the carbonation that customers love.

MIC 18-1 Parameters

| Power | 1.5Kw |

| Filling heads | 18piece |

| Sealing heads | 1piece |

| Production capacity |

1000-2500CPH based on 330ml |

| Filling temperature | 0-4 ℃ |

| Filling pressure | Max 5bar/0.5Mpa |

| Can diameter range | Ф40-90MM |

| Can height | 92-168MM |

| Dimension |

1900*1300*1950mm |

| Weight | 2100Kg |

|

1 |

Name |

Brand |

|

2 |

Push Button |

Schneider France |

|

3 |

Electromagnetic Contactor |

Schneider France |

|

4 |

Relays |

Omron Japan |

|

5 |

Frequency Converter |

Siemens |

|

6 |

Air Cylinder |

AirTAC Taiwan |

|

7 |

Electromagnetic Valve |

AirTAC Taiwan |

|

8 |

PLC Control System |

Siemens |

|

9 |

Touch Screen |

Siemens |

|

10 |

Photoelectric Switch |

Autonics |

|

11 |

Proximity Switch |

Autonics |

|

12 |

Reducer |

Zhejiang Duoli China |

RELATED PRODUCTS

MIC 12-1 Carbonated Drink Filling Machine (1000-2000CPH)

MIC 12-12-1 Carbonated Filling Machine (600-1000BPH)

MIC 18-1 Carbonated Beverage Fill Equipment (1500-2500CPH)