MIC 12-1 Soda Filling and Capping machine (1000-2000CPH)

Machine is Suitable For

The soda filling and capping machine is ideally suited for high-speed production lines in the beverage industry. It is designed to fill carbonated beverages, including sodas, sparkling waters, and other carbonated drinks. This automatic soda filler is perfect for bottling and canning companies looking for efficient and precise solutions. With its versatile functionality, it caters to various container types, from cans to bottles, offering flexibility and productivity to manufacturers worldwide.

|

|

Aluminum lid seaming system |

|

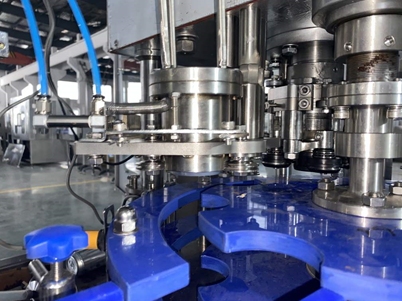

Isobaric pressure / counter pressure filling system

The 12-1 isobaric counter pressure filling system is specifically designed for aluminum cans, ensuring a smooth filling process without foaming—provided the beer temperature remains below 40°F. This system maintains a standard 1.27 cm headspace, complying with can manufacturers’ requirements to accommodate product expansion during distribution. Our filling method minimizes dissolved oxygen (DO) levels in the can, preserving product quality. Built with a high-grade 304 food-grade stainless steel tank and precision buffing, the unit ensures hygiene and durability. A CIP connection can be added upon request to support automated cleaning protocols. |

|

|

|

|

Machine Features

The soda filling and capping machine is engineered to handle both filling and capping operations in one seamless process. Key features include:

Automatic soda filler technology that ensures quick, consistent, and precise filling of each container, maintaining the carbonation of the liquid.

A soda filling system with integrated capping, reducing the need for separate machines and minimizing production time.

Advanced control systems that monitor pressure, temperature, and fill levels to ensure that each product meets quality standards.

High-speed operation, suitable for large-scale bottling and canning plants, offering high throughput without compromising on accuracy.

Durable construction with easy-to-clean materials, making it ideal for beverage production environments.

Machine Introduction

Jiangsu Mic Machinery's soda filling and capping machine combines advanced technology and industry-leading design. The automatic soda filler is part of our commitment to delivering reliable, high-performance equipment for the beverage industry. This machine is designed for ease of use, offering an intuitive interface and minimal maintenance needs. With a focus on efficiency, precision, and product integrity, it is the perfect solution for manufacturers looking to streamline their production lines. Whether you're seeking to upgrade an existing line or invest in new equipment, the soda filling and capping machine offers unbeatable reliability and performance.

Mic 12-1 Parameters

| Power | 1.1Kw |

| Filling heads | 12piece |

| Sealing heads | 1piece |

| Production capacity |

1000-2000CPH based on 330ml |

| Filling temperature | 0-4 ℃ |

| Filling pressure | Max 5bar/0.5Mpa |

| Can diameter range | Ф40-90MM |

| Can height | 92-168MM |

| Dimension |

1800*1300*1950mm |

| Weight | 1800Kg |

|

1 |

Name |

Brand |

|

2 |

Push Button |

Schneider France |

|

3 |

Electromagnetic Contactor |

Schneider France |

|

4 |

Relays |

Omron Japan |

|

5 |

Frequency Converter |

Siemens |

|

6 |

Air Cylinder |

AirTAC Taiwan |

|

7 |

Electromagnetic Valve |

AirTAC Taiwan |

|

8 |

PLC Control System |

Siemens |

|

9 |

Touch Screen |

Siemens |

|

10 |

Photoelectric Switch |

Autonics |

|

11 |

Proximity Switch |

Autonics |

|

12 |

Reducer |

Zhejiang Duoli China |

|

13 |

Sealing Motor |

Zhejiang Duoli China |

|

14 |

Barometer |

AirTAC Taiwan |

|

15 |

Bearing |

Harbin China |