MIC 18-18-6 Carbonated Drink Fill System ( 2000-3000BPH )

Machine Is Suitable For

The MIC 18-18-6 Carbonated drink fill system is designed for manufacturers seeking a reliable and efficient solution for producing carbonated beverages such as sodas, sparkling water, and energy drinks. This advanced system is suitable for filling various container types, including PET bottles, glass bottles, and aluminum cans. With its high-speed capabilities and precision, this machine meets the demands of both small and large-scale beverage production facilities.

Whether you're creating small batches of specialty drinks or handling large-scale production runs, the carbonated drink filling machine ensures consistent quality and carbonation retention, making it an indispensable asset for your production line.

|

|

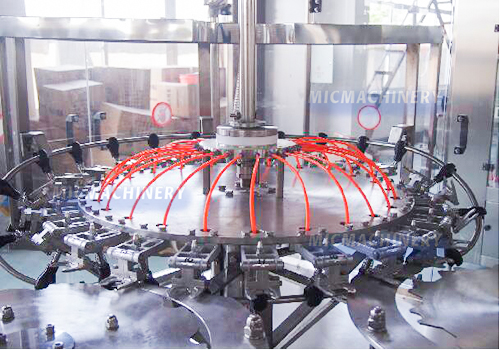

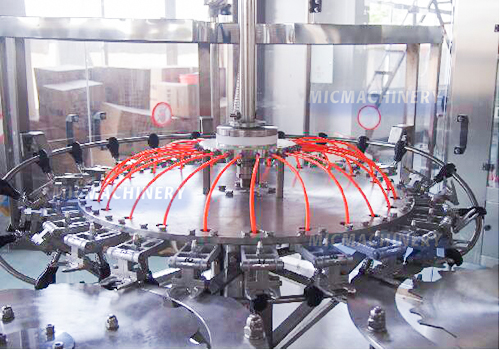

Washing Part

Washing part is mainly composed of washing pump, bottle clamps, water distributor, up turn-plate, guide rail, protection cover, spraying device, defrosting tray, rinse water take and rinse water refluxing tank. |

|

Capping Part

- Place and capping system, electromagnetic capping heads, with burden discharge function, make sure minimum bottle crash during capping |

|

Machine Features

The MIC 18-18-6 Automatic carbonated drink filler is packed with features designed to enhance efficiency, flexibility, and performance:

Three-in-One Functionality: The system integrates rinsing, filling, and capping into one seamless operation, saving time and space.

Isobaric Filling Technology: Maintains precise carbonation levels in every bottle, ensuring optimal beverage quality.

High-Speed Performance: Capable of filling and sealing up to 8,000 bottles per hour, depending on container size.

Wide Compatibility: Adapts to a variety of bottle shapes and sizes, providing flexibility for diverse product lines.

Durable Construction: Made from high-grade stainless steel, the machine is resistant to corrosion and built to last in demanding production environments.

Advanced Automation: Equipped with a PLC control system and touch screen interface for easy operation and monitoring.

Safety Features: Includes overload protection, emergency stop functions, and hygienic design to ensure safety and compliance with industry standards.

Low Energy Consumption: Designed for energy efficiency, the machine reduces operating costs while maintaining high performance.

Machine Introduction

The MIC 18-18-6 Carbonated drink fill system represents the pinnacle of precision engineering in beverage manufacturing. Developed by Jiangsu Mic Machinery, this innovative system combines advanced technology with robust construction to deliver unparalleled performance.

From rinsing and filling to capping, every stage of the production process is handled with precision and efficiency. The Automatic carbonated drink filler uses cutting-edge isobaric technology to maintain carbonation and ensure consistent fill levels. Its modular design allows for easy integration into existing production lines, while its user-friendly interface simplifies operation and monitoring.

At Jiangsu Mic Machinery, we are committed to helping manufacturers elevate their production capabilities with equipment like the MIC 18-18-6. With its superior features, durable construction, and high-speed performance, this carbonated drink filling machine is the ultimate solution for producing high-quality carbonated beverages.

|

Model |

MIC-18-18-6 |

|

Filling heads |

18pcs |

|

Capping heads |

6pcs |

|

Volume |

0.1-1.5L |

|

Production capacity |

8000-15000bottle/hr |

|

Filling method |

Normal pressure |

|

1 |

Name |

Brand |

|

2 |

Push Button |

Schneider France |

|

3 |

Electromagnetic Contactor |

Schneider France |

|

4 |

Relays |

Omron Japan |

|

5 |

Frequency Converter |

Siemens |

|

6 |

Air Cylinder |

AirTAC Taiwan |

|

7 |

Electromagnetic Valve |

AirTAC Taiwan |

|

8 |

PLC Control System |

Siemens |

|

9 |

Touch Screen |

Siemens |

|

10 |

Photoelectric Switch |

Autonics |

|

11 |

Proximity Switch |

Autonics |

|

12 |

Reducer |

Zhejiang Duoli China |

|

13 |

Sealing Motor |

Zhejiang Duoli China |

|

14 |

Barometer |

AirTAC Taiwan |

|

15 |

Bearing |

Harbin China |