MIC 18-6 Oil Filler Bottle (3000-6000BPH)

Introduction to Jiangsu Mic Machinery and the MIC 18-6 Oil Filler Bottle Machine

At Jiangsu Mic Machinery, we are committed to providing advanced packaging solutions that cater to a variety of industries. With years of expertise in manufacturing high-quality equipment, we pride ourselves on delivering innovative and reliable machinery that enhances efficiency and performance. Our MIC 18-6 oil filler bottle machine, with a capacity of 3000-6000BPH, exemplifies this dedication, offering precision and versatility for modern production lines.

|

Plastic cap screwing system

In the plastic cap screwing system for plastic bottle oil filling, the motor drives the main shaft through a transmission device, enabling the turntable to rotate smoothly. Since the central gear remains fixed, the capping heads rotate as their gears engage with the stationary gear. During operation, caps are supplied automatically through the cap feeding chute and guide rail. Bottles arriving under the capping head will receive a cap, while no bottle means no cap is released. As the capping head moves downward under cam control, the cap is pressed and screwed tightly onto the bottle. Finally, the bottles are guided forward by the star wheel for smooth delivery. |

|

|

|

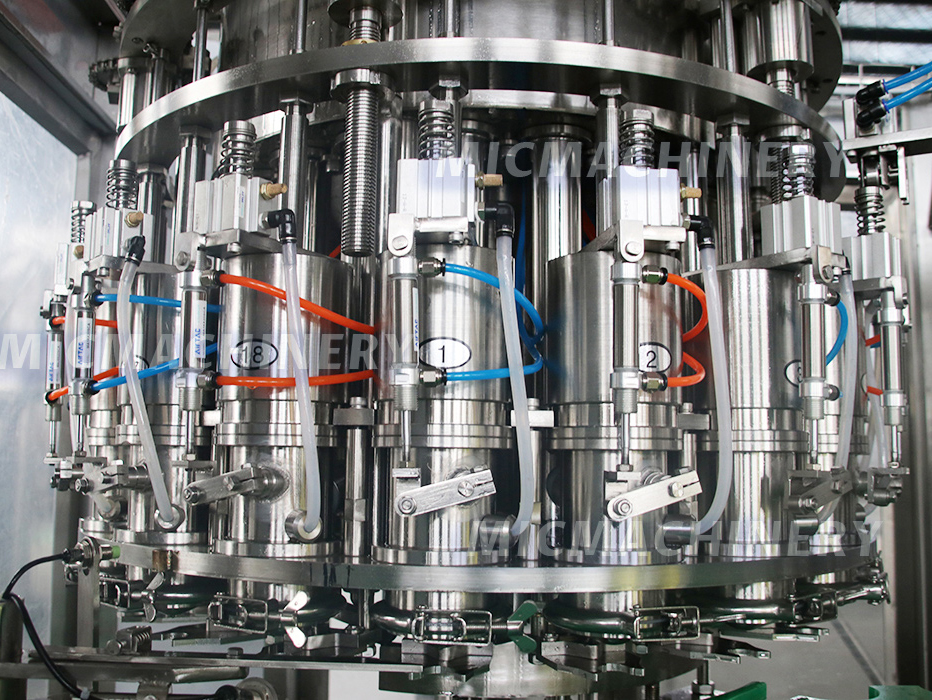

Volumetric type quantitative filling system

The volumetric type quantitative filling system for plastic bottle oil filling adopts a non-contact measuring method to ensure high accuracy and hygiene. When the measuring cup control valve opens, oil flows into the measuring cup based on the preset volume. Bottles are precisely positioned under the filling valves through the conveyor, screw, and star wheel. Once the required volume is reached, the time control system closes the measuring cup valve, guaranteeing consistent filling. To prevent dripping, a cylinder blows any residual oil from the valve outlet into the bottle, leaving a clean finish. The filled bottles are then smoothly transferred to the capping unit for sealing. |

Working Principle of the Oil Bottle Filling Machine

The MIC 18-6 oil bottle filling machine utilizes state-of-the-art volumetric filling technology to ensure consistent and accurate filling operations. Its working process can be summarized in three key steps:

1)Bottle Positioning and Preparation

Bottles are fed onto the conveyor system and precisely positioned under the filling nozzles. The machine's automatic detection system ensures that every bottle is properly aligned before the filling process begins.

2)Filling Process

The volumetric filling system accurately dispenses the pre-set quantity of liquid into each bottle. This ensures uniform filling, making the machine suitable for various oils, including cooking oil, motor oil, and lubricants.

3)Sealing and Packing

After filling, the bottles are automatically capped and sealed. The system integrates seamlessly with downstream equipment, enabling efficient transitions to the oil bottle packing machine for labeling and final packaging.

Advantages of the Oil Bottle Filling Machine

High-Speed Performance

With a capacity of 3000-6000 bottles per hour, the MIC 18-6 oil bottle filling machine is ideal for medium- to large-scale production lines.

1、Precision Filling

The volumetric filling system guarantees precise measurements, minimizing product waste and ensuring consistent quality in every oil filler bottle.

2、Adaptability

This machine accommodates a wide range of bottle sizes and shapes, making it versatile for various production requirements.

3、Durable Construction

Built from high-grade stainless steel, the machine offers excellent durability and is resistant to corrosion, ensuring long-lasting performance even in demanding environments.

4、User-Friendly Interface

The intuitive control panel makes it easy to set up, operate, and monitor the machine, reducing the need for extensive training and enhancing operational efficiency.

5、Seamless Integration

Designed for compatibility with other packaging equipment, such as the oil bottle packing machine, the MIC 18-6 allows for a streamlined production process.

Conclusion

The MIC 18-6 oil filler bottle machine from Jiangsu Mic Machinery stands as a testament to our commitment to innovation, quality, and efficiency. With its advanced features and robust design, this machine is an excellent choice for businesses looking to enhance their oil packaging operations. Trust Jiangsu Mic Machinery to deliver reliable solutions that elevate your production capabilities and drive success.

|

Power |

3Kw |

|

Filling heads |

18piece |

|

Sealing heads |

6piece |

|

Filling volume range |

0.5-2L |

|

Production capacity |

3000-6000CPH based on 500ml |

|

Filling temperature |

room temperature |

|

Bottle diameter range |

Ф60-120MM |

|

Bottle height |

180-380MM |

|

Air pressure |

0.6-0.8Mpa |

|

Air consumption |

0.8-1.0m³/min |

|

Dimension |

2400×1400×2500mmm |

|

Weight |

2500Kg |

|

Name |

Brand |

|

Touch screen |

Siemens (Germany) |

|

Buttons |

Schneider (France) |

|

AC Contactor |

Schneider (France) |

|

PLC |

Mitsubishi (Japan) / Siemens (Germany) |

|

Frequency changer |

Schneider (France) |

|

Breaker |

Schneider (France) |

|

Air cylinder |

AirTAC (China) / FESTO (Optional) |

|

Solenoid valve |

AirTAC (China) / FESTO (Optional) |

|

Relay |

Omron (Japan) / Schneider (France) |

|

photoelectric sensor |

Autonics (Korea) / Omron (Optional) |

|

Proximity switch |

Autonics / Omron (Optional) |