MIC 8 Head Semi Automatic Beer Filling Machine (200-800BPH)

MIC 8 Head Semi-Automatic Beer Filling Machine (200-800BPH): Efficient, Reliable, and Cost-Effective

Jiangsu Mic Machinery is a leading provider of innovative beer packaging equipment that enhances the efficiency and quality of production lines. We specialize in designing and manufacturing beer filling machines and other packaging solutions for breweries of all sizes.

|

|

Capping Head A Capping Head is an essential component in packaging machinery, used to securely seal bottles, jars, and other containers with various types of caps, ensuring product integrity and safety. |

|

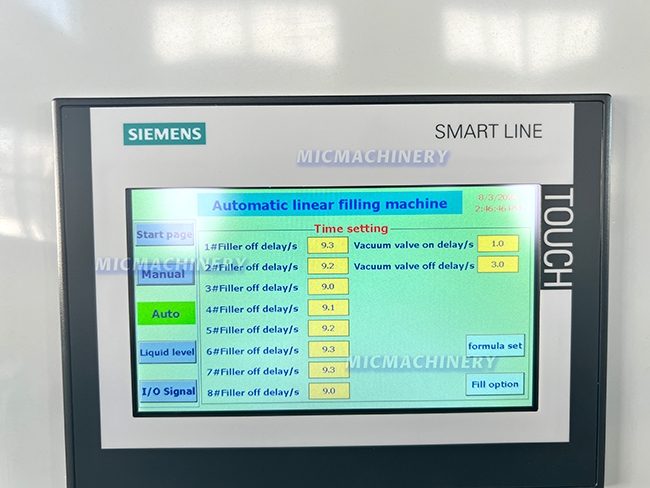

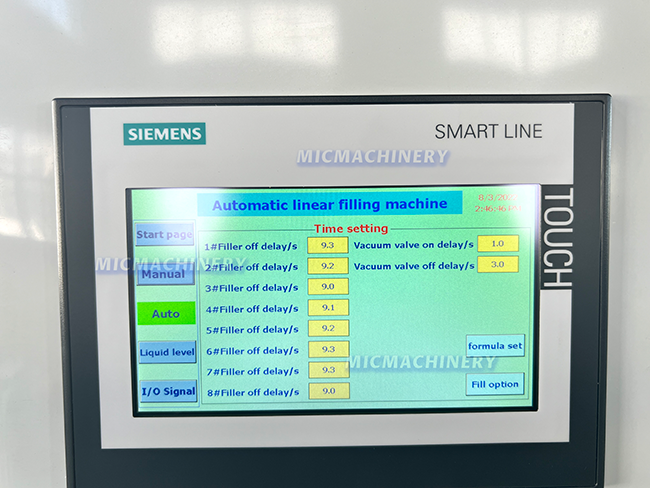

control panel A Control Panel is a user interface in machinery that allows operators to monitor and control machine functions, adjusting settings for optimal performance, safety, and efficiency in production.

|

|

|

|

Filling Head A Filling Head is a key component in filling machinery, responsible for accurately dispensing liquids or powders into containers. It ensures precise filling levels, improving efficiency and minimizing waste during production. |

Equipment Introduction of MIC 8 Head Semi-Automatic Beer Filling Machine (200-800BPH)

The MIC 8 Head semi-automatic beer filling machine is designed for breweries seeking a balance between manual and automated processes. With a production capacity of 200 to 800 bottles per hour, this beer packaging machine is perfect for small to mid-sized breweries or for breweries that need to optimize filling for limited batch production.

Semi-Automatic Operation: Unlike fully automated machines, the MIC 8 Head semi-automatic beer filling machine requires manual assistance for some operations, such as placing and removing bottles. However, the filling process itself is fully automated, allowing for accurate and consistent filling with minimal effort from operators.

Precise Filling Process: The machine features precise filling heads that minimize foam formation and ensure that each bottle is filled to the exact level. This is essential for maintaining the flavor and carbonation of the beer, ensuring high-quality output with each batch.

Multi-Head Design: With 8 filling heads, this beer packaging equipment allows for higher throughput compared to single-head machines, significantly improving filling efficiency while retaining the quality of the beer.

Versatile for Different Bottle Sizes: The MIC 8 Head machine can be easily adjusted to handle different bottle sizes, making it adaptable for breweries that package their beer in a variety of formats. Whether you're filling standard bottles, specialty bottles, or larger sizes, this machine is flexible enough to meet your brewery's needs.

Durable and Compact Construction: Made from high-quality stainless steel, the MIC 8 Head beer packaging machine is built to last and endure the demands of continuous operation. Its compact design ensures that it occupies minimal floor space while providing maximum efficiency, making it ideal for breweries with limited space.

Easy Maintenance and Operation: This beer filling machine is designed with ease of use in mind. It features a simple interface and straightforward controls, allowing operators to quickly learn how to operate and maintain the machine. Routine maintenance is also simplified, helping to minimize downtime and keep the production line running smoothly.

Advantages of the Semi-Automatic Beer Filling Machine

The MIC 8 Head semi-automatic beer filling machine provides several key advantages that make it an excellent choice for breweries with moderate production needs.

1、Cost-Effective Solution

The semi-automatic operation of this beer packaging equipment makes it a more affordable choice for small to medium-sized breweries. It provides the benefits of automation without the high upfront costs associated with fully automatic machines.

2、Flexibility in Production

Whether you're producing small or medium batches of beer, the MIC 8 Head filling machine offers the flexibility needed to adapt to varying production requirements. Its adjustable settings and versatile design allow for different bottle sizes and beer types, making it a reliable solution for diverse production lines.

3、Increased Efficiency

The machine's multi-head design (8 heads) ensures that multiple bottles can be filled simultaneously, increasing throughput and overall efficiency. The combination of semi-automatic operation and multiple filling heads strikes an ideal balance between manual input and high-volume output.

4、Consistent Beer Quality

With automated filling technology, the MIC 8 Head ensures that each bottle is filled consistently, reducing the chances of overfilling or underfilling. This is crucial for maintaining product quality, particularly for craft breweries where every batch matters.

5、Easy Integration into Existing Lines

The MIC 8 Head semi-automatic beer packaging machine is easy to integrate into an existing production line. Its compact design and ease of operation make it a seamless addition to your brewery, helping to enhance your production process without the need for extensive retraining or complicated adjustments.

6、Low Maintenance Costs

The machine's simple design and stainless steel construction minimize the need for costly repairs and maintenance. Routine maintenance tasks are easy to carry out, reducing the risk of production delays.

Conclusion

The MIC 8 Head semi-automatic beer filling machine is an excellent choice for breweries that want high-quality, reliable beer packaging equipment without the high costs associated with fully automated systems. Offering a filling capacity of 200 to 800 bottles per hour, this versatile machine combines ease of use, cost-effectiveness, and efficiency, making it an ideal solution for small to medium-scale breweries. With precise filling, durable construction, and flexible operation, the MIC 8 Head semi-automatic beer filling machine is designed to enhance your brewery's production capacity while maintaining the quality and consistency of your beer.

| Power | 0.3Kw |

| Filling heads | 4-10 heads |

| Capping heads | 4-10 heads |

| Production capacity | 200-800CPH |

| Bottle diameter range | Ф50-90MM |

| Bottle height | 150-300MM |

| Dimension | 2000*700*2000mm |

| Weight | 150Kg |

|

Name |

Brand |

|

|

1 |

Push Button |

Schneider France |

|

2 |

Electromagnetic Contactor |

Schneider France |

|

3 |

Relays |

Omron Japan |

|

4 |

Frequency Converter |

Siemens |

|

5 |

Air Cylinder |

AirTAC Taiwan |

|

6 |

Electromagnetic Valve |

AirTAC Taiwan |

|

7 |

PLC Control System |

Siemens |

|

8 |

Touch Screen |

Siemens |

|

9 |

Photoelectric Switch |

Autonics |

|

10 |

Proximity Switch |

Autonics |

|

11 |

Reducer |

Zhejiang Duoli China |

|

12 |

Sealing Motor |

Zhejiang Duoli China |

|

13 |

Barometer |

AirTAC Taiwan |

|

14 |

Bearing |

Harbin China |