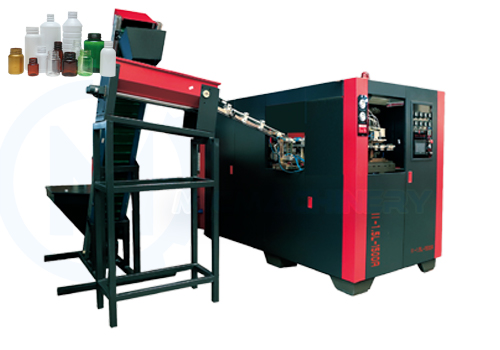

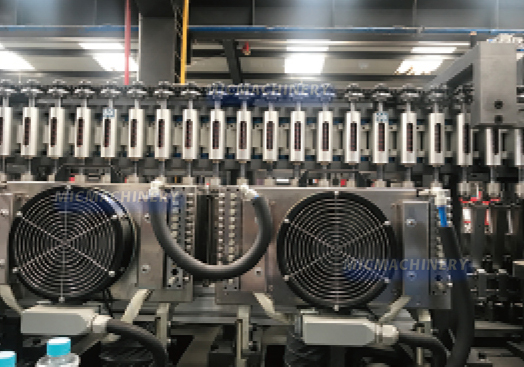

MIC-IV-2L-4500A Automatic Blow Molding Machine

High-Performance Automatic Blow Molding Machine for PET Bottles

Our automatic blow molding machine is designed to support efficient, stable, and high-quality PET bottle production. Equipped with advanced heating and blowing technology, it ensures precise bottle forming, uniform wall thickness, and smooth surface finish. This machine is suitable for manufacturers seeking reliable automation and consistent output in modern packaging lines.

Stable Automation and Precision Control

The system operates with intelligent control and optimized mechanical design, enabling continuous production with minimal manual intervention. Accurate temperature regulation and air pressure control help reduce material waste while improving bottle consistency. As a result, the machine performs reliably in long-term, high-capacity operations.

Trusted Equipment from Experienced Suppliers

As one of the professional blow molding machine manufacturers, we focus on durable construction, efficient performance, and long service life. Each machine is built using high-quality components and tested to ensure operational stability. We also provide technical support and customization options to meet different production requirements.

Cost Efficiency and Investment Value

The PET blow molding machine price is influenced by factors such as output capacity, automation level, and configuration. Our machines are designed to balance performance and cost efficiency, helping customers reduce operating costs while achieving consistent production results over time.

Application Areas

The automatic blow molding machine is widely used for producing:

• Beverage bottles such as water and soft drinks

• Cosmetic and personal care containers

• Pharmaceutical and chemical bottles

• Household liquid packaging

With reliable automation, strong production stability, and competitive PET blow molding machine price, our solution from experienced blow molding machine manufacturers is an ideal choice for upgrading or expanding PET bottle production lines.

|

|

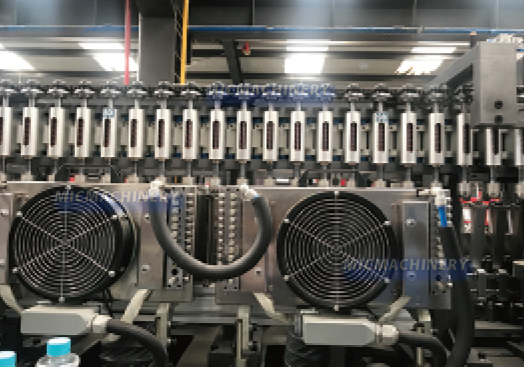

MIC automatic energy-saving rotating machine features a continuous preform feeding structure, which reduces the overall machine footprint. The preforms do not need to be rotated, resulting in simplified processing steps. |

| A continuous heating system is adopted, with a heating distance of 50 mm between preforms, enabling intensive heating, reducing lamp heating space, and significantly improving preform heating efficiency and energy savings of up to 25%–30%. The heating box offers a simple structure, easy operation, and convenient lamp replacement and maintenance. |

|

|

|

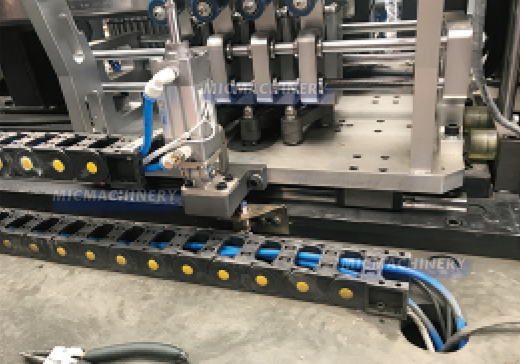

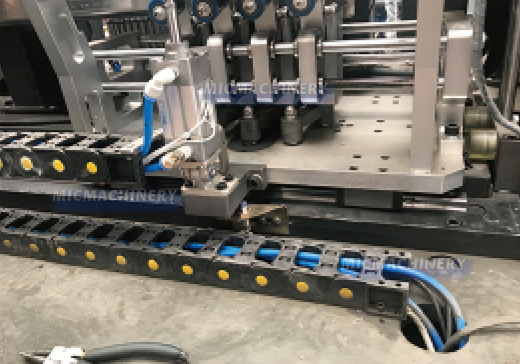

The transfer arm is driven by a servo motor and designed with a variable pitch system. The servo motor precisely controls pitch changes to ensure high-speed operation and accurate positioning. The machine frame adopts a servo-driven linkage structure for opening and closing the mold and bottom mold. A high-speed, high-precision blowing valve set is used to further improve output efficiency. The human–machine interface operating system ensures simple and user-friendly operation. |

| Model&Name | MIC-IV-2L-4500A |

| Overall Dimensions(mm) Length*Width*Height | Main machine: 5200*2200*2650 |

| Elevator: 3500*2700*2700 | |

| Weight | 8 ton |

| No. of Cavities | 2 cav. |

| Cavity Pitch | 228 mm |

| Max. Capacity | 2 litre |

| Heating Pitch | 63.5 mm |

| No. of Perform Holders | 110 PCS |

| Preform Neck (inner dia.) | 28~42 mm |

| Preform Height (max) | 190 mm |

| Bottle Inner Diameter (max) | 140 mm |

| Bottle Height (max) | 350 mm |

| No. of Heating Ovens | 8 unit |

| No. of Infrared Lamps | 80 pcs |

| Max. Heating Power | 48 kw |

| Specified Power Consumption | 75 kw |

| Voltage | 380V 50/60hz |

| Theoretical Production (Based on 150ml; Preform: 28g; Round Bottle) | 4800 pcs/h |