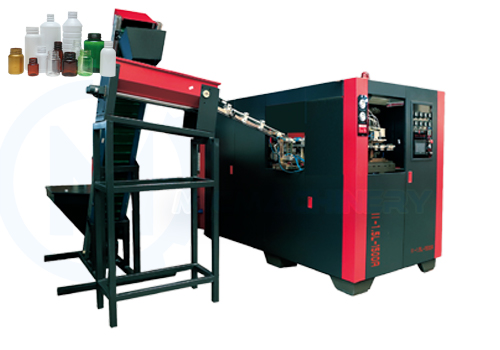

MIC-II-0.8L-2800A Blow Molding Machine

High-Efficiency Blow Molding Machine for PET Bottle Production

Our blow molding machine is designed to meet the needs of modern packaging and manufacturing. It efficiently produces hollow PET containers, including beverage bottles, cosmetic jars, and pharmaceutical bottles. With precise control over heating and molding, each container is uniform, durable, and lightweight, ensuring high-quality results for every production batch.

Features of Our Automatic PET Blow Molding Machine

Our automatic PET blow molding machine offers advanced automation and reliable performance:

• High Efficiency: Fully automated operation ensures continuous production and reduces labor requirements.

• Precision Control: Advanced systems regulate temperature, pressure, and timing for consistent bottle quality.

• Versatility: Produces bottles of different sizes and shapes, suitable for beverages, cosmetics, and household products.

• Energy Efficiency: Optimized design reduces energy consumption while maintaining high-speed performance.

• Durable Products: PET bottles are strong enough for transport but remain lightweight for easy handling.

This machine is ideal for manufacturers who require speed, precision, and consistent quality in their production lines.

Factors Affecting PET Blow Molding Machine Price

The PET blow molding machine price varies depending on capacity, automation level, brand, and optional features such as multi-layer molding or quick-change systems. Our machines balance cost-effectiveness with high performance, making them a smart investment for long-term production efficiency.

Applications

Our blow molding machine is widely used across multiple industries:

• Beverage Industry: Water, soda, and juice bottles.

• Pharmaceuticals: Medicine bottles and liquid containers.

• Cosmetics: Shampoo, lotion, and personal care containers.

• Household Products: Cleaning liquids, detergents, and other liquid containers.

With our automatic PET blow molding machine, manufacturers can achieve reliable, high-speed production while maintaining consistent quality, making it an essential addition to any PET packaging line.

|

|

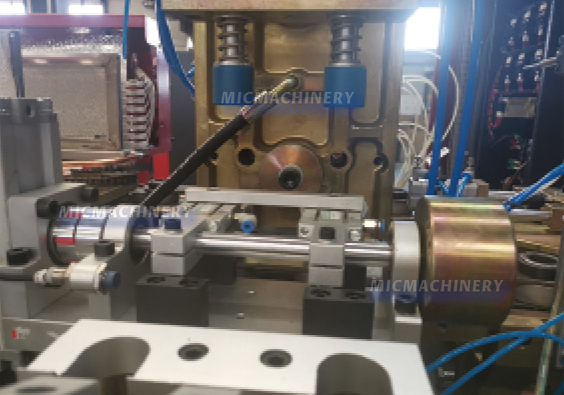

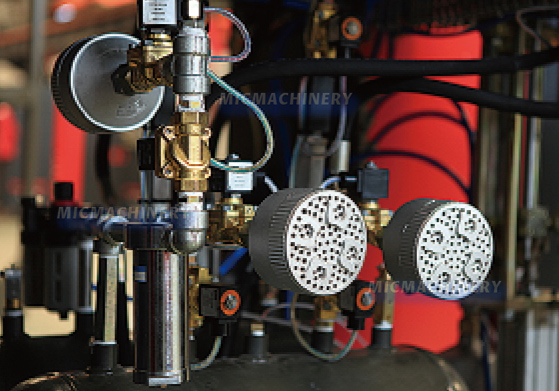

MIC series of bottle blowing machine adopts Man-Machine interface control and easy to operate with high rate of finished bottle. |

| It adopts modular assembly design, so it's easy to maintenance. |

|

|

|

It has many advantages including cover a little area, high efficiency, energy conservation and cost, etc. |

| Model&Name | MIC-II-0.8L-2800A |

| Overall Dimensions(mm) Length*Width*Height | Main machine: 2100*1450*2200 |

| Elevator: 1900*1050*2300 | |

| Weight | 1.5 ton |

| No. of Cavities | 2 cav. |

| Cavity Pitch | 100 mm |

| Max. Capacity | 0.8 litre |

| Heating Pitch | 100 mm |

| No. of Perform Holders | 42 PCS |

| Preform Neck (inner dia.) | 18~38 mm |

| Preform Height (max) | 130 mm |

| Bottle Inner Diameter (max) | 85 mm |

| Bottle Height (max) | 265 mm |

| No. of Heating Ovens | 1 unit |

| No. of Infrared Lamps | 16 pcs |

| Max. Heating Power | 20 kw |

| Specified Power Consumption | 32 kw |

| Voltage | 380V 50/60hz |

| Theoretical Production (Based on 150ml; Preform: 28g; Round Bottle) | 2800 pcs/h |