MIC Automatic Juice Pouch Filling Machine (3000PPH)

Jiangsu Mic Machinery: Leading the Future of Beverage Packaging

At Jiangsu Mic Machinery, we specialize in providing advanced solutions for the beverage and food industries. As a leading manufacturer of automated filling and packaging machinery, our commitment to innovation and quality is reflected in our extensive range of products, including the highly efficient MIC automatic juice pouch filling machine (3000BPH). With years of industry experience and a focus on technological advancement, we deliver reliable machinery that enhances production efficiency, ensuring a seamless experience for our clients.

|

|

Capper Station A Capper Station is a key component in packaging lines, automatically applying caps to bottles or containers. It ensures precise capping, increases production efficiency, and minimizes human error. |

|

Cap arranging unit A Cap Arranging Unit efficiently organizes and arranges caps for automatic capping machines, ensuring smooth production flow, reducing downtime, and enhancing overall packaging efficiency. |

|

|

|

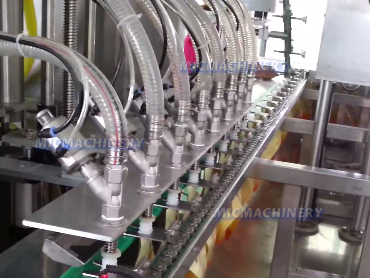

Filling Head A Filling Head is a crucial part of liquid filling machines, designed to accurately dispense liquids into bottles or containers. It ensures consistent filling volume, reduces spills, and enhances production efficiency. |

Working Principle of the MIC Automatic Juice Pouch Filling Machine

The juice pouch filling machine operates with precision and efficiency, utilizing advanced technology to ensure fast, hygienic, and accurate filling of juice into pouches. The system works by automatically transporting empty pouches along the conveyor line to the filling station. Once in place, the machine fills each pouch with a preset amount of juice. The process is further enhanced with an automatic sealing function, ensuring tight and secure seals on every pouch. The pouch juice filling machine is designed to maintain high standards of hygiene with its easy-to-clean components, preventing contamination during the filling process. This automatic system is ideal for large-scale production, capable of filling up to 3000 pouches per hour, making it an efficient solution for juice manufacturers.

Advantages of the MIC Automatic Juice Pouch Filling Machine

The juice packet machine offers numerous advantages that make it an excellent choice for juice producers seeking high-quality and reliable filling solutions:

1、High-Speed Production

Capable of filling up to 3000 pouches per hour, this juice pouch filling machine ensures high throughput, making it perfect for large-scale production lines.

2、Precise Filling

The machine guarantees accurate filling, minimizing waste and ensuring each pouch contains the correct amount of juice. This precision improves product consistency and reduces operational costs.

3、Automatic Operation

With its fully automated system, the pouch juice filling machine reduces the need for manual intervention, resulting in lower labor costs and a more streamlined production process.

4、Hygienic Design

The machine is designed with food-grade materials and features that facilitate easy cleaning, ensuring the juice remains uncontaminated and maintaining hygiene standards throughout the operation.

5、Durability and Reliability

Built with robust materials, the juice packet machine is engineered to withstand continuous use, offering a long lifespan and minimal downtime for maintenance.

6、Flexible Pouch Sizes

This machine is adaptable to a variety of pouch sizes, providing flexibility for manufacturers to package different volumes of juice based on market demand.

Jiangsu Mic Machinery’s MIC automatic juice pouch filling machine represents the pinnacle of efficiency, reliability, and quality in the beverage packaging industry, helping businesses scale their operations while maintaining the highest standards.

| Filling Range | 250-2000ml |

| Voltage | 220v/380v |

| Power | 4KW |

| Filling Precision | 99% |

| Filling Nozzles | 8 nozzles |

| Filling Speed | 3000 BPH |

| Dimension | 3800*1500*2200mm |

| Weight | 1000kg |

| Material | SS304 |

| Touch screen | Xinjie |

| PLC | Schneider |

| Solenoid valve | AirTAC |

| Optoelectronic system | AUTONICS |

| Differential switch | Netherlands |

| Air source treatment | AirTAC |

| Switching power | MingWei |

| Button and other low-voltage electrical appliances | Schneider |

| Alarm system | Real-time fault alarm, important fault can automatically stop |

| Servo motor | TECO |

| Ball screw | Taiwan |

| Function | Filling the count |

| Material | 316 stainless steel is used in contact with material, 304 stainless steel is used in other main parts. |

| Sealing ring | It is made of carbon tetrafluoro fibers with good anticorrosion, wear resistance and sealing. |

| AC contactor | Schneider |

| Thermorelay | Schneider |

| Transducer | Schneider |

| Double clutch | Custom |

| Precision relief valve | Lark |

| Screw cap form | Automatic cap sorting and capping |

| One camera dual use | Fillable Water Agent or Thickener Formula |