MIC Small Pouch Juice Filling Machine (20-40SPM)

Jiangsu Mic Machinery: Innovating Packaging Solutions for the Beverage Industry

Jiangsu Mic Machinery is a trusted leader in the design and manufacture of high-performance filling and packaging machinery. With a strong commitment to innovation and quality, we provide cutting-edge solutions for the beverage, food, and packaging industries. Our extensive range of products includes automated systems designed to improve production efficiency and ensure high-quality results. Among these solutions is the MIC Small pouch juice filling machine (20-40BPM), which offers precision, speed, and versatility for small-scale juice production. At Jiangsu Mic Machinery, we strive to offer reliable equipment that meets the evolving needs of our clients while maintaining the highest industry standards.

|

|

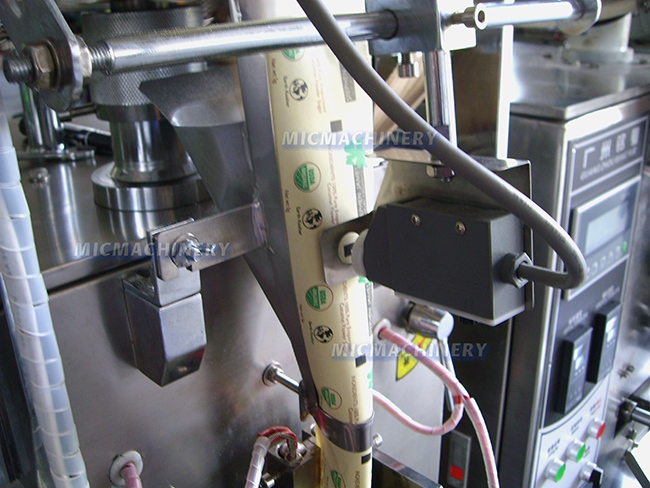

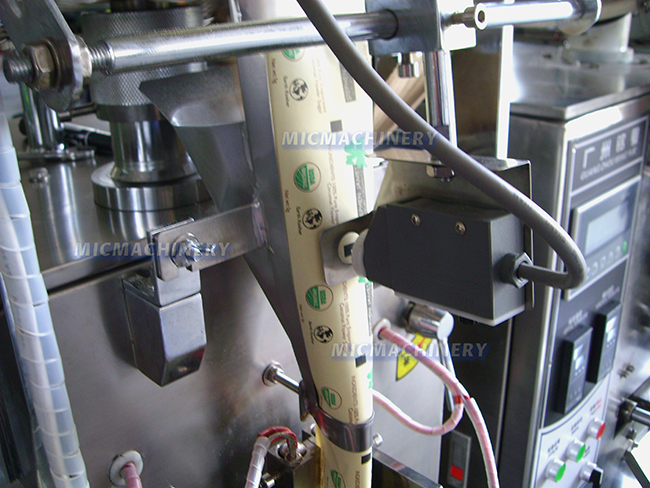

Bag Former A Bag Former is a machine used in packaging to shape and form bags from flat rollstock film. It ensures consistent bag formation, increases production speed, and maintains packaging quality in automated systems. |

|

Sensor A Sensor is a device that detects and responds to changes in the environment, such as temperature, pressure, or motion. It provides real-time data, ensuring automation systems function accurately and efficiently. |

|

|

|

Control Panel A Control Panel is an interface used to monitor and manage the operation of machines or production lines. It provides real-time control, settings adjustments, and ensures smooth, efficient operation. |

Equipment Introduction: MIC Small Pouch Juice Filling Machine (20-40BPM)

The pouch juice filling machine is designed to meet the growing demand for efficient, small-batch juice packaging. With a filling capacity of 20-40 pouches per minute, this machine is ideal for businesses looking to produce smaller quantities of juice while maintaining a high level of precision and consistency. The juice packet machine operates through a fully automated system, ensuring that each pouch is filled accurately and sealed tightly for optimal freshness and quality.

This juice pouch filling and sealing machine features a high level of automation, reducing the need for manual intervention and improving overall productivity. The system includes an easy-to-use interface for setting parameters, allowing operators to adjust the filling volume and sealing time as needed. Its compact design makes it suitable for businesses with limited space, offering a reliable solution for small-scale juice production.

Key features of the pouch juice filling machine include:

1、High Accuracy

The machine ensures precise filling and sealing, minimizing waste and ensuring consistent product quality across each pouch.

2、Speed and Efficiency

Capable of filling 20-40 pouches per minute, the juice packet machine maximizes production rates for small-scale operations without sacrificing quality.

3、Hygienic and Easy to Clean

The machine is constructed from food-grade materials and designed for easy disassembly, making it simple to clean and maintain hygiene standards.

4、Versatile Design

Suitable for various pouch sizes, this juice pouch filling and sealing machine offers flexibility for juice manufacturers seeking to meet diverse market demands.

5、Low Operating Costs

The efficient design reduces energy consumption and minimizes maintenance, resulting in lower operating costs for businesses.

The MIC Small pouch juice filling machine (20-40BPM) is an ideal solution for businesses seeking an affordable, reliable, and efficient filling and sealing machine for small-scale juice production.

| Capcity | 20- 40 bags/min | |

| Range of measurement | 1- 100 G | |

| Bag size | (L) 20-160 (W) 20-100mm | |

| Sealing Type | Back sealing | |

| Power | 1180W | |

| Total power | 380V/50HZ 220V/50-60HZ | |

| Packing material | Paper/the polyethylene,nylon/polyethylene,tea filter paper,etc | |

| Net weight | 2 60kg | |

| Overall dimensions | (L) 800*(W) 800*(H) 1800 | |

| Sensor | Changtong (China) |

| PLC Controller | Mitsubishi/J apan |

| Stepping motor | Jiangsu huanyu |

| Main Motor | Zhaoqing Zhongbao |