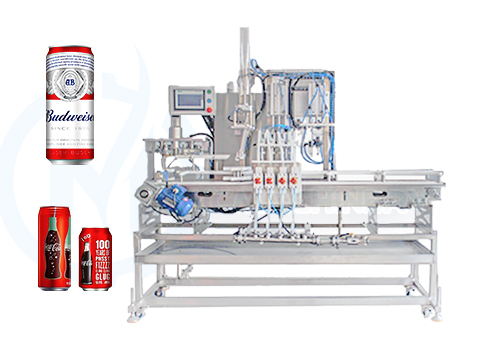

MIC Linear Beverage Canning Machine (1000-1500CPH)

Company Introduction

Jiangsu Mic Machinery is a trusted leader in the beverage production industry, specializing in the design and manufacture of advanced filling and packaging machinery. With years of expertise and innovation, we are committed to providing high-quality solutions that meet the needs of modern beverage manufacturers. Our MIC Linear beverage canning machine reflects our dedication to precision, efficiency, and reliability, making us a preferred choice for businesses worldwide.

|

|

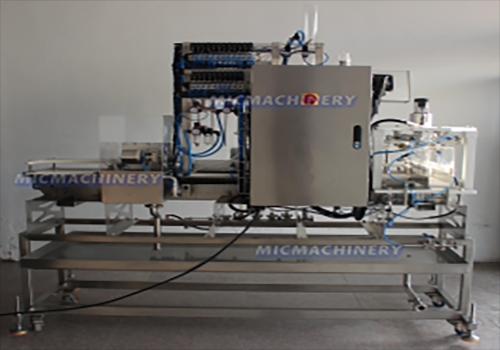

Machine |

|

Filling head The beer canning machine filling head ensures precise and consistent filling, using advanced technology to control beer volume and minimize waste. Designed for efficiency, it supports high-speed operations while maintaining product quality. |

|

|

|

Conveyor |

Features of Filling Machinery Beverage Canning Machine

The MIC Linear beverage canning machine is engineered to deliver exceptional performance and versatility. Its innovative design incorporates advanced technology, ensuring seamless operation across various production environments. Key features include:

High-Precision Filling System:The beverage can filling machine uses advanced nozzles and sensors to deliver accurate and consistent fills, reducing waste and maintaining product quality.

Adjustable Capacity:Designed to handle a range of can sizes, this machine offers flexibility for manufacturers producing multiple beverage lines.

Hygienic Operation:With an integrated rinsing system and stainless steel construction, the machine ensures hygienic processing, preventing contamination and preserving the freshness of beverages.

Automation and Control:Equipped with a PLC control system, the MIC Linear beverage canning equipment allows precise adjustments and monitoring, optimizing efficiency while reducing manual intervention.

Energy Efficiency:The machine is designed to minimize energy consumption, contributing to cost savings and sustainable operations.

Compact Design:Its linear structure enables space-saving installation, making it ideal for factories with limited floor space.

Advantages of Beverage Canning Machine

1、Enhanced Productivity

The MIC Linear beverage canning machine offers high-speed filling capabilities, enabling manufacturers to meet demanding production targets with ease.

2、Reliability and Durability

Built with robust materials and cutting-edge components, this machine is designed to provide long-lasting performance, reducing downtime and maintenance costs.

3、Versatility

As a multi-functional beverage can filling machine, it is suitable for carbonated drinks, juices, and other beverages, ensuring adaptability to diverse production needs.

4、User-Friendly Operation

The intuitive interface and automated features make the machine easy to operate and maintain, enhancing operational efficiency.

5、Consistent Quality Assurance

The machine's precision systems ensure that each can is uniformly filled and sealed, guaranteeing consistency and customer satisfaction.

Global Standards Compliance

Jiangsu Mic Machinery's beverage canning equipment meets international safety and quality standards, ensuring reliability and trustworthiness in every production environment.

At Jiangsu Mic Machinery, we strive to deliver state-of-the-art solutions like the MIC Linear beverage canning machine to support your business’s success. Trust us to provide unparalleled expertise and equipment for your beverage production needs.

|

Equipment Parameter |

MIC 4-4-1 Beer Can Rinser Filler Seamer |

|

|

1 |

Dimension (L*W*H) |

2.00×0.91×1.85M |

|

2 |

Equipment Weight |

400KG |

|

3 |

Packing Size (L*W*H) |

2.20×1.15×2.05M |

|

4 |

Packing Weight |

550KG |

|

5 |

Production Capacity |

1200- 1500pcs/ H(330ml) 396-495L/ H 1000- 1200pcs/ H(500ml) 500-600L/ H |

|

6 |

Voltage |

380V-3 Phases-50Hz (Customized) |

|

7 |

Power port |

3P+ N+G |

|

8 |

Power consumption |

2.0-3.5KW |

|

9 |

Main Material |

SUS304 |

|

10 |

Beer Storage Tank Pressure |

0.15-0.2Mpa (22-30PSI) 1.5" Tir-clamp |

|

11 |

Compressed Air |

0.5-0.7Mpa (75.0- 105PSI) OD:Ф10mm |

|

12 |

Jacking Can Pressure |

0.20-0.30Mpa (30-45PSI) |

|

13 |

CO2 Pressure |

0.15-0.2Mpa (22-30PSI) OD:Ф10mm |

|

14 |

Flip- Rinse Pressure |

0.15-0.20Mpa(22-30PSI) 1.5" Tir-clamp |

|

15 |

Exit- Rinse Water Pressure |

0.15-0.20Mpa(22-30PSI) 1.5" Tir-cl |