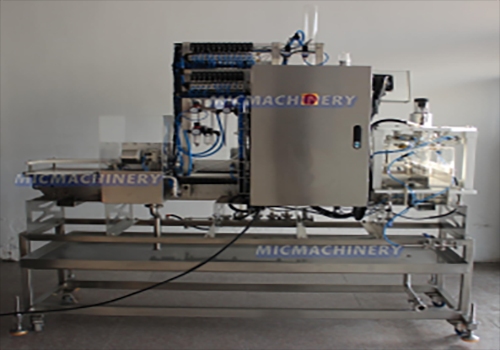

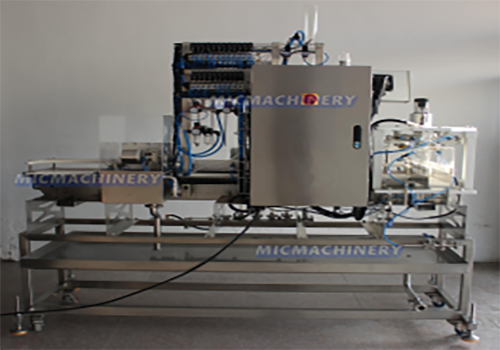

MIC Linear Soda Filling and Capping Machine (1000-1500CPH)

MIC Linear Soda Filling and Capping Machine

Company Introduction

Jiangsu Mic Machinery is a trusted leader in the field of beverage filling and packaging equipment. Our company is dedicated to providing high-quality, reliable, and innovative machines for the beverage industry. We specialize in offering advanced solutions tailored to various needs, including the soda filling and capping machine, designed to meet the demands of both small and large-scale production lines. By combining precision engineering with years of industry experience, we help our customers optimize their production processes with the most efficient filling and capping technologies.

|

|

Machine |

|

Filling head The beer canning machine filling head ensures precise and consistent filling, using advanced technology to control beer volume and minimize waste. Designed for efficiency, it supports high-speed operations while maintaining product quality. |

|

|

|

Conveyor |

Working Principle of Soda Filling Machine

The MIC Manual soda filling and capping machine operates using a straightforward yet effective filling process that ensures high-quality results. The machine is designed for manual operation, where operators fill bottles by aligning them under the filling nozzles. The system uses gravity or pressure to fill the bottles with soda, while also maintaining the carbonation level. After filling, bottles are manually capped by the operator, ensuring a secure seal. While it is not as automated as an automatic soda filling machine, it provides an efficient and cost-effective solution for smaller production volumes or businesses looking for a more hands-on approach to soda production.

The soda filling and capping machine uses simple controls to allow operators to adjust the fill level as needed, making it ideal for businesses that require flexibility and ease of use. This machine is best suited for smaller production lines or businesses just beginning to scale their beverage production, offering reliable performance without the need for complex automation systems.

Advantages of Soda Filling Machine

The MIC Manual soda filling and capping machine offers a number of advantages for smaller production lines or companies looking for a more flexible, hands-on approach to filling soda bottles:

1、Cost-Effective

This machine is a more affordable option for businesses with lower production volumes, offering a practical solution without the higher upfront costs of an automatic soda filling machine.

2、Manual Control

Operators can manually control the filling process, allowing for greater flexibility when adjusting fill levels or making changes to the filling procedure.

3、Simplicity and Ease of Use

The machine's simple design makes it easy to operate, with minimal training required for staff. This makes it an excellent choice for smaller businesses or startups entering the soda production fill line.

4、Space-Efficient

The compact design of the soda filling and capping machine means that it takes up less space compared to automated systems, making it ideal for smaller production areas or businesses with limited floor space.

5、Consistency and Reliability

Despite its manual operation, the machine is built to last and delivers consistent results. Bottles are filled with precision, and capping is performed securely to maintain product quality.

For companies looking to enter the soda production market or those with lower production needs, the MIC Manual soda filling and capping machine offers a cost-effective and reliable solution. This machine combines simplicity, flexibility, and durability, making it a valuable addition to any smaller-scale beverage production line.

|

Equipment Parameter |

MIC 4-4-1 Beer Can Rinser Filler Seamer |

|

|

1 |

Dimension (L*W*H) |

2.00×0.91×1.85M |

|

2 |

Equipment Weight |

400KG |

|

3 |

Packing Size (L*W*H) |

2.20×1.15×2.05M |

|

4 |

Packing Weight |

550KG |

|

5 |

Production Capacity |

1200- 1500pcs/ H(330ml) 396-495L/ H 1000- 1200pcs/ H(500ml) 500-600L/ H |

|

6 |

Voltage |

380V-3 Phases-50Hz (Customized) |

|

7 |

Power port |

3P+ N+G |

|

8 |

Power consumption |

2.0-3.5KW |

|

9 |

Main Material |

SUS304 |

|

10 |

Beer Storage Tank Pressure |

0.15-0.2Mpa (22-30PSI) 1.5" Tir-clamp |

|

11 |

Compressed Air |

0.5-0.7Mpa (75.0- 105PSI) OD:Ф10mm |

|

12 |

Jacking Can Pressure |

0.20-0.30Mpa (30-45PSI) |

|

13 |

CO2 Pressure |

0.15-0.2Mpa (22-30PSI) OD:Ф10mm |

|

14 |

Flip- Rinse Pressure |

0.15-0.20Mpa(22-30PSI) 1.5" Tir-clamp |

|

15 |

Exit- Rinse Water Pressure |

0.15-0.20Mpa(22-30PSI) 1.5" Tir-clamp |