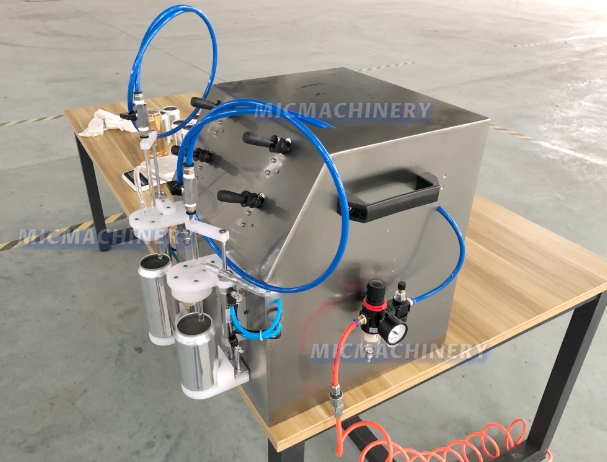

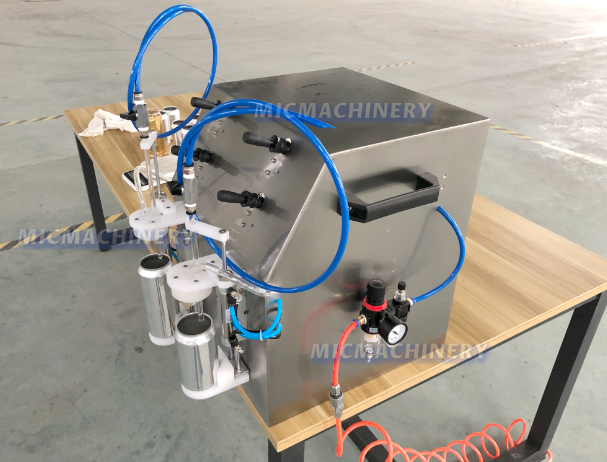

MIC Manual Beverage Can Filling Machine (8CPM)

Company Introduction

Jiangsu Mic Machinery is a globally recognized leader in the manufacturing of advanced beverage packaging machinery. With years of experience and expertise, we specialize in providing high-quality solutions tailored to the diverse needs of the beverage industry. Our MIC manual beverage can filling machine exemplifies our commitment to precision, reliability, and customer satisfaction. As one of the leading carbonated beverage can filling machine manufacturers, we strive to deliver innovative and efficient equipment for a wide range of applications.

|

|

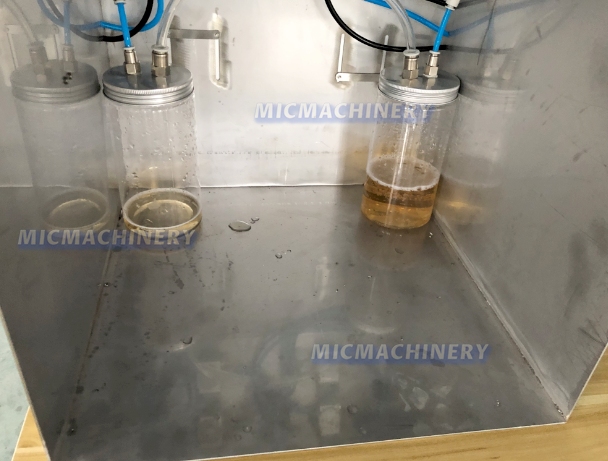

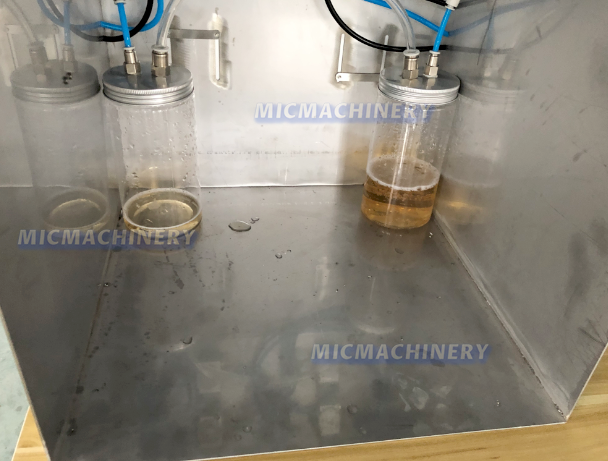

Filling Head The filling head of our beer canning machine ensures precise and consistent filling. It features advanced technology for accurate volume control, minimizing waste while maintaining high-quality standards in every can. |

|

Control Button |

|

|

|

Material Barrel The material barrel of our beer canning machine is designed for durability and efficient beer storage. Made from high-quality, corrosion-resistant materials, it ensures safe, hygienic handling and easy access during the filling process. |

Working Principle of Beverage Canning Machine

The MIC manual beverage can filling machine operates on a straightforward and efficient mechanism, making it an excellent choice for small to medium-scale production. The process begins with the manual placement of empty cans on the filling platform. Once positioned, the machine’s precision nozzles dispense the beverage into the cans with exceptional accuracy, minimizing spillage and foam.

For carbonated beverages, the machine is designed to handle pressure-sensitive operations, ensuring proper filling without compromising the carbonation levels. After filling, the cans are manually sealed using a sealing unit integrated into the system. Despite its manual operation, the MIC manual beverage canning equipment incorporates advanced features to ensure consistent results and ease of use.

Advantages of Beverage Canning Machine

1、Compact and User-Friendly Design

The MIC manual beverage can filling machine is designed for simplicity and convenience. Its compact size allows for easy installation in smaller production spaces, while its intuitive controls make it easy to operate.

2、High Precision and Consistency

The machine’s precision filling system ensures accurate and uniform fills, maintaining consistent product quality. This feature is especially valuable for carbonated drinks, where maintaining carbonation is critical.

3、Versatility

As one of the trusted carbonated beverage can filling machine manufacturers, we’ve designed this machine to accommodate various beverage types, including carbonated drinks, juices, and teas, as well as different can sizes.

4、Cost-Effective Solution

The manual operation of this beverage canning equipment provides a budget-friendly option for smaller businesses or those venturing into beverage production, while still delivering professional-grade results.

5、Durability and Low Maintenance

Constructed from high-quality materials, this machine is built to withstand demanding operations with minimal maintenance requirements, ensuring long-term reliability.

6、Hygienic and Safe

The MIC manual beverage can filling machine meets stringent hygiene standards, with easy-to-clean components that prevent contamination and maintain product integrity.

Jiangsu Mic Machinery’s MIC manual beverage canning equipment is the perfect blend of affordability, efficiency, and quality. Whether you’re a small-scale producer or exploring new production possibilities, this machine offers a reliable solution to meet your beverage canning needs.

| Filling Heads | 2 Pieces |

| Production Capacity |

8 Cans per minute based on 330 ML and 550 ML |

| Filling Pressure | 0.4-0.6Mpa |

| Can Diameter Range | Ф40-90MM |

| Can Height | 92-168MM |

| Dimension | 575*550*480MM |

| Weight | 15KG |

| Name | Brand |

| Buttons | Schneider (France) |

| Touch screen | Siemens (Optional) |

| AC Contactor | Schneider (France) |

| PLC | Mitsubishi (Japan) / Siemens (Optional) |

| Frequency changer | Schneider (France) |

| Air cylinder | AirTAC (China) / FESTO (Optional) |

| Solenoid valve | AirTAC (China) / FESTO (Optional) |

| Relay | Omron (Japan) / Schneider (France) |

| Photoelectric sensor | Autonics (Korea) / Omron (Optional) |

| Proximity switch | Autonics / Omron (Optional) |