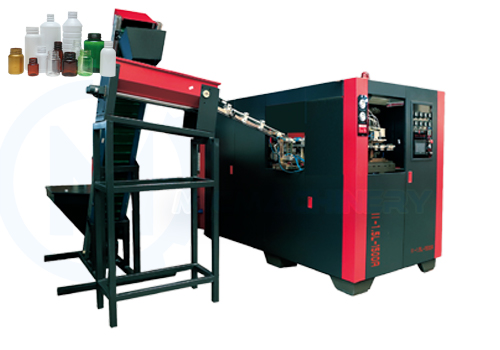

MIC-IV-0.8L-6000A PET Blow Molding Machine

High-Efficiency PET Blow Molding Machine for Bottle Production

Our PET blow molding machine is designed to deliver stable, high-speed production of PET bottles with excellent consistency and durability. Using advanced heating and precision blowing technology, the machine ensures uniform wall thickness and smooth bottle surfaces, meeting the quality requirements of modern packaging lines.

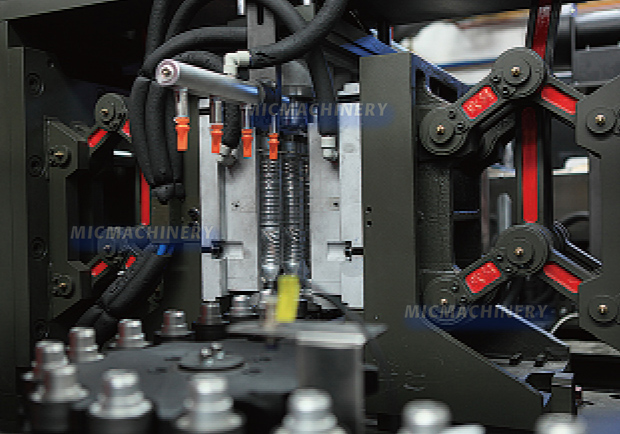

Reliable Performance and Precision Forming

This bottle blow molding machine features an optimized air circulation system and accurate temperature control to achieve precise bottle shaping. Its robust mechanical structure supports continuous operation, helping manufacturers maintain reliable output and minimize downtime. The system is suitable for producing bottles in various sizes and shapes to meet different packaging needs.

Cost-Effective and Market-Ready Solution

Engineered for efficiency and long-term operation, this equipment offers a practical balance between performance and investment value. For manufacturers looking for a blow molding machine for sale, this solution delivers dependable quality, easy operation, and strong adaptability across production environments.

Application Industries

The PET blow molding machine is widely used in:

• Beverage packaging such as water and soft drink bottles

• Cosmetic and personal care containers

• Pharmaceutical and chemical bottles

• Household liquid product packaging

With stable performance, flexible production capability, and proven reliability, this bottle blow molding machine is an ideal choice for businesses seeking a high-quality blow molding machine for sale to expand or upgrade their bottle manufacturing line.

|

|

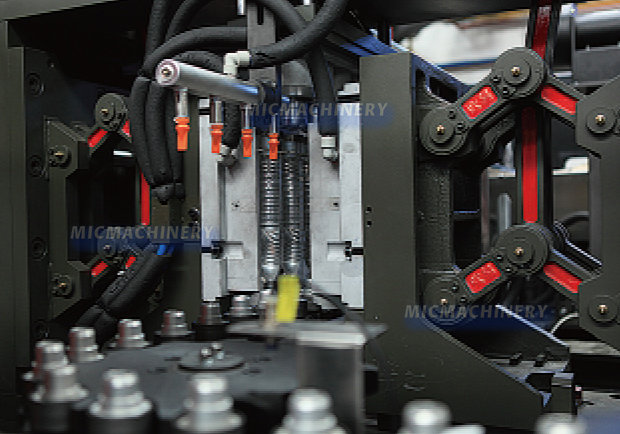

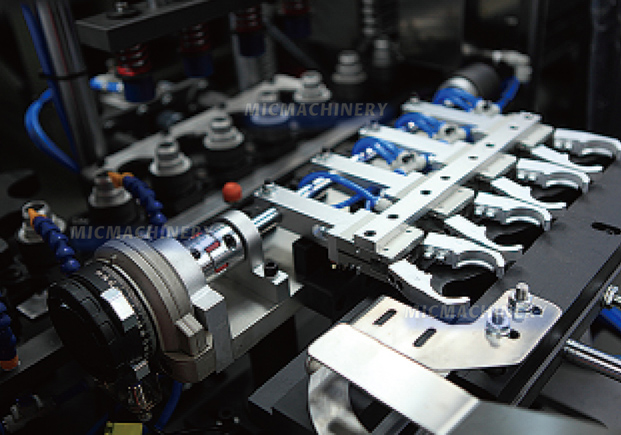

MIC servo series is a high-end linear bottle blowing machine independently researched and developed by our company in accordance with market requirements. |

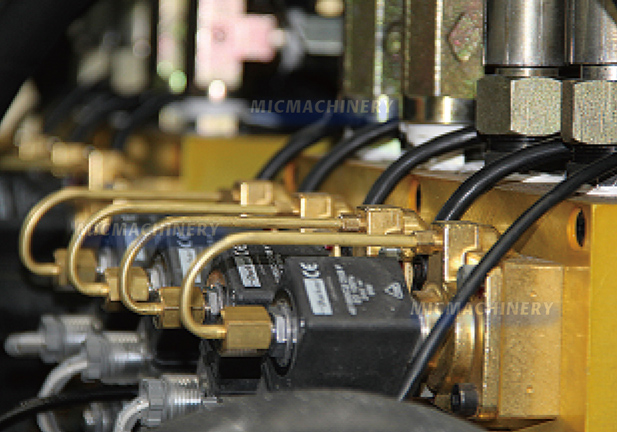

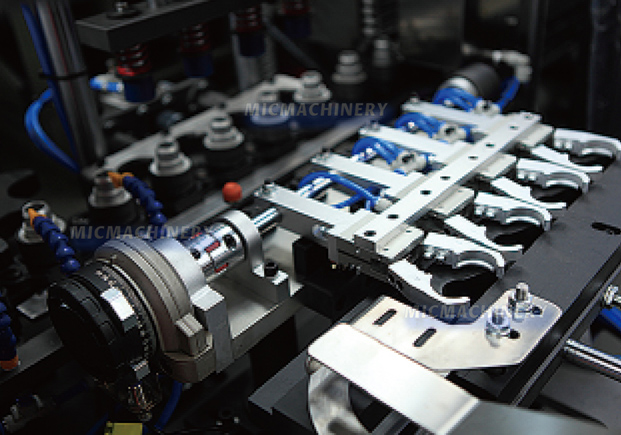

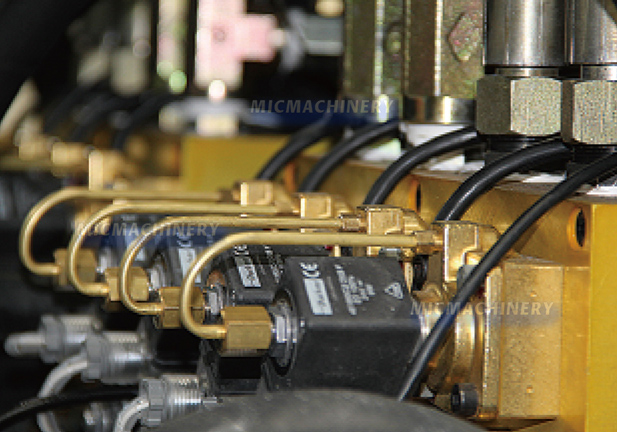

| It adopts a high-performance servo precision system, an efficient and energy-saving heating system, an accurate preform feeding system, and a stable, high-efficiency bottle blowing system. |

|

|

|

The machine is equipped with an air recycling device, eliminating the need for an additional low-pressure air supply system. It offers multiple advantages, including low energy consumption, high precision, and strong operational stability. |

| Model&Name | MIC-IV-0.8L-6000A |

| Overall Dimensions(mm) Length*Width*Height | Main machine: 3100*2200*2200 |

| Elevator: 2700*2700*3500 | |

| Weight | 3.5 ton |

| No. of Cavities | 4 cav. |

| Cavity Pitch | 76.2 mm |

| Max. Capacity | 0.8 litre |

| Heating Pitch | 76.2 mm |

| No. of Perform Holders | 86 PCS |

| Preform Neck (inner dia.) | 15~38 mm |

| Preform Height (max) | 130 mm |

| Bottle Inner Diameter (max) | 70 mm |

| Bottle Height (max) | 280 mm |

| No. of Heating Ovens | 4 unit |

| No. of Infrared Lamps | 32 pcs |

| Max. Heating Power | 40 kw |

| Specified Power Consumption | 64 kw |

| Voltage | 380V 50/60hz |

| Theoretical Production (Based on 150ml; Preform: 28g; Round Bottle) | 6000 pcs/h |