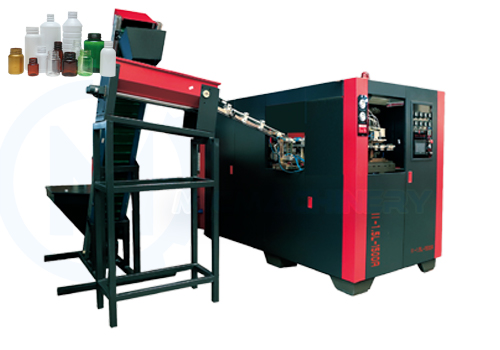

MIC-II-2.5L-1500A PET Bottle Blowing Machine

High-Quality PET Bottle Blowing Machine for Efficient Production

Our PET bottle blowing machine is designed for high-speed and precise production of PET bottles used in beverages, cosmetics, pharmaceuticals, and household products. It ensures uniform, durable, and lightweight bottles while optimizing production efficiency. This equipment is ideal for manufacturers seeking reliable and consistent results in their PET bottle production lines.

Features of Our Fully Automatic Bottle Blowing Machine

The fully automatic bottle blowing machine integrates advanced automation with robust design to deliver superior performance:

• High Production Efficiency: Continuous automated operation reduces labor and increases output.

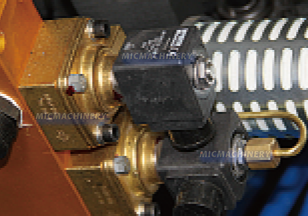

• Precision Control: Advanced systems regulate temperature and pressure for consistent bottle quality.

• Versatility: Capable of producing bottles of various shapes, sizes, and wall thicknesses.

• Energy Efficiency: Optimized design lowers energy consumption while maintaining high-speed operation.

• Durable Products: Bottles are strong enough to withstand transport yet remain lightweight.

This machine is perfect for manufacturers who need speed, precision, and reliability in PET bottle production.

Why Choose Our PET Bottle Blow Molding Machine

As a trusted PET bottle blow molding machine, our equipment is built with premium materials and advanced technology for long-term reliability. We provide excellent after-sales support and can customize solutions according to production capacity, bottle specifications, and operational requirements. Choosing our machines ensures high-quality output with minimal downtime.

Applications

The PET bottle blowing machine is suitable for multiple industries:

• Beverages: Water, juice, soda, and other drink bottles.

• Pharmaceuticals: Medicine bottles and liquid containers.

• Cosmetics: Shampoo, lotion, and personal care containers.

• Household Products: Cleaning liquids, detergents, and other liquid containers.

Investing in a fully automatic bottle blowing machine or PET bottle blow molding machine allows manufacturers to achieve high-speed, precise, and consistent PET bottle production, making it a smart and cost-effective choice for any production line.

|

|

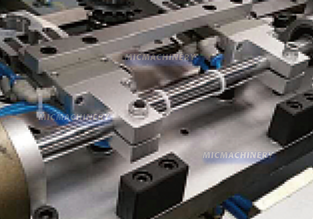

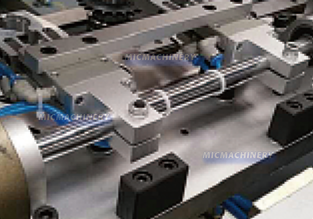

MIC series of bottle blowing machine adopts Man-Machine interface control and easy to operate with high rate of finished bottle. |

| It adopts modular assembly design, so it's easy to maintenance. |

|

|

|

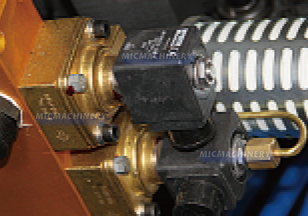

It has many advantages including cover a little area, high efficiency, energy conservation and cost, etc. |

| Model&Name | MIC-II-2.5L-1500A |

| Overall Dimensions(mm) Length*Width*Height | Main machine: 1900*1900*2400 |

| Elevator: 2000*1200*2700 | |

| Weight | 2.5 ton |

| No. of Cavities | 2 cav. |

| Cavity Pitch | 140 mm |

| Max. Capacity | 2.5 litre |

| Heating Pitch | 66 mm |

| No. of Perform Holders | 54 PCS |

| Preform Neck (inner dia.) | 18~45 mm |

| Preform Height (max) | 180 mm |

| Bottle Inner Diameter (max) | 125 mm |

| Bottle Height (max) | 370 mm |

| No. of Heating Ovens | 1 unit |

| No. of Infrared Lamps | 40 pcs |

| Max. Heating Power | 18 kw |

| Specified Power Consumption | 20 kw |

| Voltage | 380V 50/60hz |

| Theoretical Production (Based on 150ml; Preform: 28g; Round Bottle) | 1500 pcs/h |