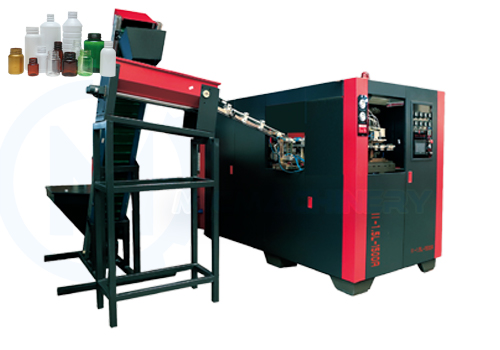

MIC-IV-0.8L-4500A Plastic Blow Molding Machine

High-Performance Plastic Blow Molding Machine for Bottle Production

Our plastic blow molding machine is engineered to deliver reliable, high-efficiency production of plastic bottles for a wide range of industries. Designed with precision molding technology and stable mechanical performance, it produces uniform, lightweight, and durable bottles that meet modern packaging standards. This machine is ideal for manufacturers seeking consistent quality and long-term operational reliability.

Advanced Performance and Stable Operation

The machine adopts optimized heating and blowing systems to ensure accurate bottle forming and smooth surface finish. With intelligent control and robust structural design, it supports continuous operation while maintaining stable output. The plastic bottle blowing machine is suitable for producing bottles of different shapes and capacities, making it adaptable to diverse production requirements.

Cost-Effective Investment

The blow molding machine price is influenced by configuration, automation level, and production capacity. Our equipment is designed to balance performance and cost efficiency, helping customers achieve lower operating costs and higher return on investment. Durable components and energy-efficient systems further reduce maintenance and energy expenses over time.

Wide Range of Applications

This plastic blow molding machine is widely used in multiple industries, including:

• Beverage packaging such as water and soft drink bottles

• Cosmetic and personal care containers

• Pharmaceutical and chemical bottles

• Household and industrial liquid containers

With stable performance, flexible bottle design capability, and competitive blow molding machine price, our plastic bottle blowing machine is a dependable solution for manufacturers looking to improve production efficiency and product consistency.

|

|

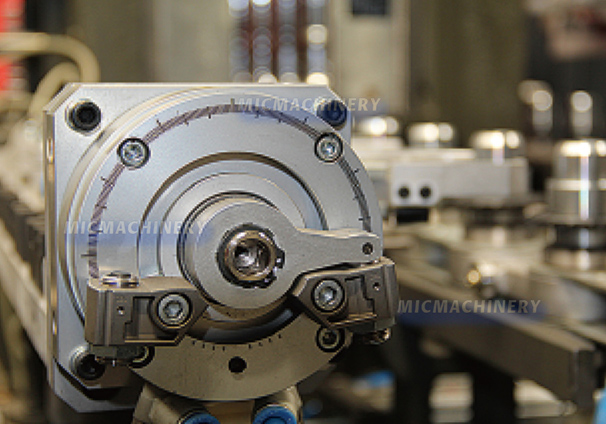

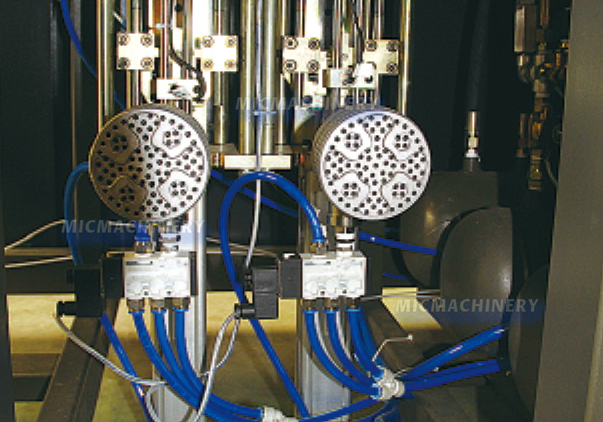

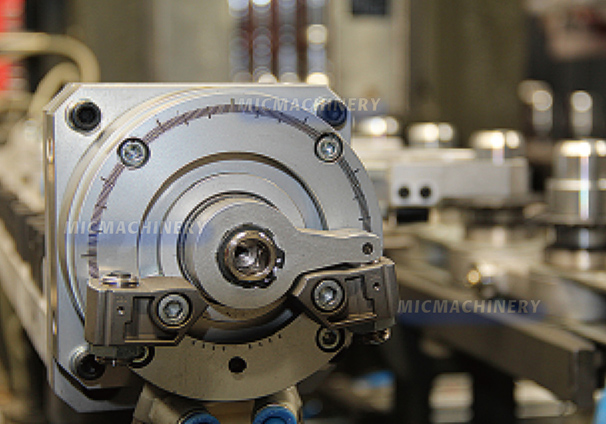

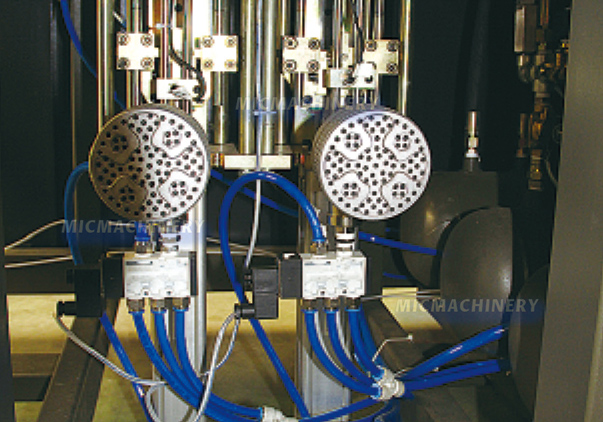

MIC series of bottle blowing machine adopts Man-Machine interface control and easy to operate with high rate of finished bottle. |

| It adopts modular assembly design, so it's easy to maintenance. |

|

|

|

It has many advantages including cover a little area, high efficiency, energy conservation and cost, etc. |

| Model&Name | MIC-IV-0.8L-4500A |

| Overall Dimensions(mm) Length*Width*Height | Main machine: 3400*1600*2200 |

| Elevator: 2700*2700*3500 | |

| Weight | 3.5 ton |

| No. of Cavities | 4 cav. |

| Cavity Pitch | 80 mm |

| Max. Capacity | 1 litre |

| Heating Pitch | 80 mm |

| No. of Perform Holders | 84 PCS |

| Preform Neck (inner dia.) | 18~38 mm |

| Preform Height (max) | 130 mm |

| Bottle Inner Diameter (max) | 75 mm |

| Bottle Height (max) | 280 mm |

| No. of Heating Ovens | 1 unit |

| No. of Infrared Lamps | 32 pcs |

| Max. Heating Power | 30 kw |

| Specified Power Consumption | 64 kw |

| Voltage | 380V 50/60hz |

| Theoretical Production (Based on 150ml; Preform: 28g; Round Bottle) | 4500 pcs/h |