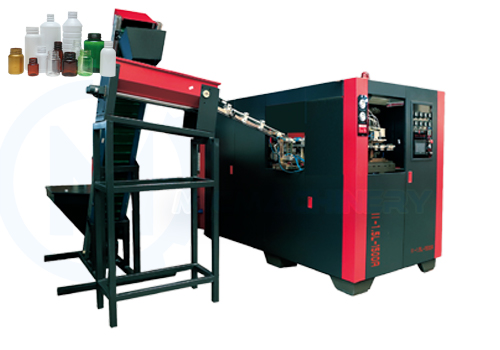

MIC-VII-R-12000A Plastic Bottle Blowing Machine

Plastic Bottle Blowing Machine: Function, Performance, and Technical Overview

The plastic bottle blowing machine is an essential piece of equipment in the beverage, cosmetic, and chemical industries. Designed for the high-efficiency production of PET and other plastic bottles, this machine ensures consistent quality while optimizing production costs. Many businesses rely on blow molding machine technology to manufacture bottles of various shapes and sizes, from small 100ml containers to large 2-liter bottles.

Function of the Plastic Bottle Blowing Machine

The primary function of a plastic bottle blowing machine is to transform preforms into fully formed plastic bottles. Preforms, which are essentially test-tube-shaped pieces of PET or other plastics, are heated and then inflated inside a mold using compressed air. The machine ensures that the bottles have the correct dimensions, wall thickness, and uniformity.

Modern blow molding machines often feature fully automated processes, including preform feeding, heating, stretching, and cooling. This automation not only reduces labor costs but also enhances production speed and consistency. Some advanced machines are integrated with sensors to detect defects and ensure that only bottles meeting quality standards proceed to the next stage.

Technical Principle

The operation of a plastic bottle blowing machine relies on the blow molding principle. This involves several key steps:

1. Preform Loading: Preforms are loaded into the machine, either manually or via automatic feeding systems.

2. Heating: The preforms are heated to the proper temperature, making the plastic pliable enough for molding.

3. Stretching and Blowing: The heated preform is placed in a mold. A stretch rod elongates the preform while compressed air inflates it, forming the final bottle shape.

4. Cooling: The mold is cooled to solidify the plastic, preserving the bottle’s shape and strength.

5. Ejection: The finished bottles are ejected and sent for labeling, filling, or packaging.

This process ensures precise control over the bottle’s structural integrity and minimizes material waste.

Performance and Advantages

Plastic bottle blowing machines offer several advantages that make them indispensable for modern bottle production:

• High Efficiency: Capable of producing hundreds to thousands of bottles per hour.

• Consistency: Ensures uniform wall thickness and shape, reducing the rate of defective bottles.

• Energy Saving: Advanced models are designed with energy-efficient heating and air compression systems.

• Flexibility: Supports different bottle sizes and shapes without extensive retooling.

• Automation: Reduces manual labor and allows continuous operation with minimal supervision.

In addition, maintenance is straightforward, and most modern blow molding machines are designed for easy part replacement and long-term durability.

Choosing the Right Manufacturer

Selecting a reliable blow molding machine manufacturer is crucial for ensuring product quality and machine longevity. Top manufacturers provide technical support, spare parts availability, and after-sales service. They also offer machines that comply with international safety and quality standards. Partnering with reputable blow molding machine manufacturers ensures that businesses receive consistent production output and can scale operations efficiently.

Applications

The versatility of a plastic bottle blowing machine allows it to be used in various industries, including:

• Beverage Industry: Producing bottles for water, juice, and soft drinks.

• Cosmetics: Manufacturing containers for shampoos, lotions, and personal care products.

• Chemicals: Producing bottles for cleaning agents, detergents, and other liquid chemicals.

Its ability to handle different bottle sizes, shapes, and materials makes it a flexible and cost-effective solution for businesses of all scales.

|

|

The heating box features a simple structure and easy operation, with lamps that are easy to replace and maintain. The shift hand is driven by a servo motor with a variable pitch design. |

| The servo motor controls the pitch change to ensure high-speed operation and precise positioning. The frame uses a servo-driven linkage structure for opening and closing the mould and bottom mould. A high-speed, precision blowing valve set effectively improves output, while the human-machine interface operating system allows for simple and intuitive operation. |

|

| Model&Name | MIC-VII-R-12000A |

| Overall Dimensions(mm) Length*Width*Height | Main machine: 5300*2200*2550 |

| Elevator: 3100*1500*3500 | |

| Weight | 8.5 ton |

| No. of Cavities | 7 cav. |

| Cavity Pitch | 80 mm |

| Max. Capacity | 0.8 litre |

| Heating Pitch | 50 mm |

| No. of Perform Holders | 148 PCS |

| Preform Neck (inner dia.) | 20~30 mm |

| Preform Height (max) | 150 mm |

| Bottle Inner Diameter (max) | 75 mm |

| Bottle Height (max) | 270 mm |

| No. of Heating Ovens | 4 unit |

| No. of Infrared Lamps | 32 pcs |

| Max. Heating Power | 48 kw |

| Specified Power Consumption | 75 kw |

| Voltage | 380V 50/60hz |

| Theoretical Production (Based on 150ml; Preform: 28g; Round Bottle) | 12000 pcs/h |