MIC Semi-Automatic Beverage Canning Sealing Equipment (15CPM)

MIC Semi-Automatic Beverage Canning Sealing Equipment

Mic Machinery is a trusted manufacturer specializing in professional canning and packaging solutions for the beverage industry. With extensive experience in global exports, we focus on creating compact, efficient, and easy-to-operate systems. Our beverage canning equipment is used in craft beverage startups, pilot labs, and commercial-scale facilities that require quality, consistency, and reliability.

|

|

Machine This compact and modern beer canning machine features a sleek white design with a transparent viewing area and an intuitive control panel. Its clean and professional appearance suits breweries and beverage businesses, ensuring functionality with aesthetic appeal. |

|

Control Panel The control panel of our beer canning machine is designed for ease of use, offering intuitive controls. |

|

|

|

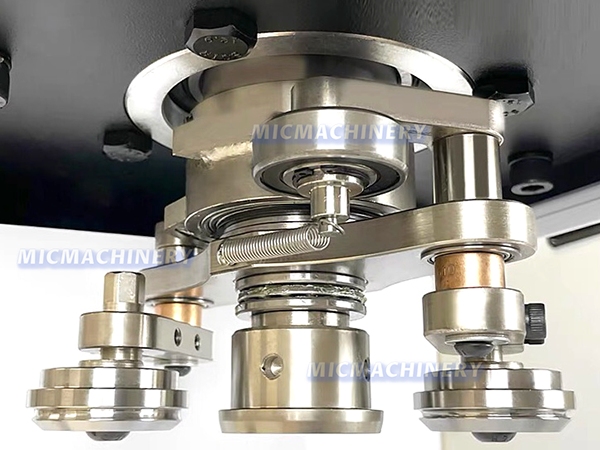

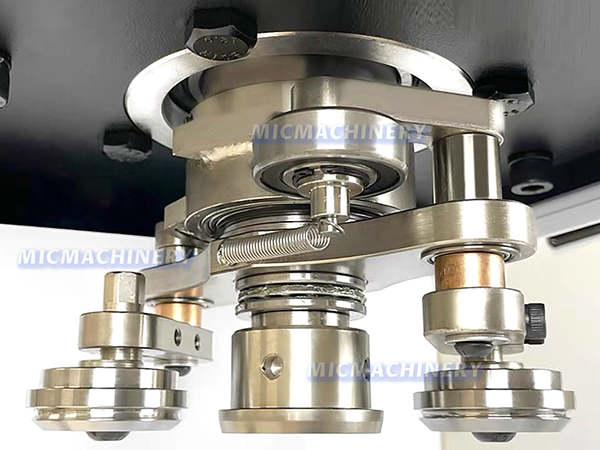

Capping Station A Capping Station is an essential part of the filling and packaging process, designed to securely apply caps to jars, or cans, ensuring product safety and preventing leaks or contamination. |

Working Principle

The MIC Semi-Automatic Beverage Canning Sealing Equipment works through a simple and precise canning cycle designed for ease of use and consistent performance:

1)Can placement: The operator manually places a filled can on the platform.

2)Clamping: A mechanical arm secures the can to ensure perfect positioning.

3)Sealing: The machine activates a rotary sealing head to seal the lid firmly.

4)Release: The sealed can is unclamped and removed, ready for labeling or packaging.

This method ensures optimal sealing quality and preserves carbonation or liquid freshness.

Functional Advantages

This beverage canning sealing equipment offers several advantages tailored to small- and medium-scale beverage producers:

▪ Compact and robust stainless-steel body for long-term durability

▪ Compatible with a variety of can sizes and lid types

▪ High sealing accuracy for both carbonated and non-carbonated drinks

▪ Easy to operate with minimal training

▪ Seamless integration with a beverage can filling machine for a complete production line

▪ Sealing capacity of up to 30 cans per minute, depending on operator pace

Its balance of automation and manual control gives users excellent flexibility.

Applications

The MIC Semi-Automatic Beverage Canning Sealing Equipment is widely used in small beverage factories, craft drink workshops, and test-run production environments. It's particularly effective for operations with seasonal output or limited space. When combined with a beverage can filling machine, it creates a streamlined solution for soda, sparkling water, juice, energy drinks, and beer.

Conclusion

The MIC Semi-Automatic Beverage Canning Sealing Equipment provides an efficient, compact solution for beverage producers seeking dependable sealing performance. Whether you're expanding a small-scale operation or refining your current beverage canning equipment, this machine ensures professional sealing with easy operation and flexible integration.

| Weight | 52kg |

| Voltage | 220V 50Hz |

| Packaging Type | CANS, Bottles |

| Dimension | 255*455*608mm |

| Motor power | 0.55KW |

| Filling speed | 15 cans each minute |