MIC Semi Automatic Carbonated Drink Filling Machine (200-800CPH)

Machine is Suitable For

The small carbonated drink filling machine is perfect for medium-scale beverage producers looking for a reliable and efficient filling solution. It is suitable for a variety of industries, including soft drinks, carbonated juices, flavored waters, and energy drinks. Ideal for small to medium production runs, the carbonated drink filling machine is widely used in production facilities where flexibility and precision are essential. This semi-automatic machine is adaptable to various bottle types and sizes, making it a versatile addition to any beverage production line.

|

|

Capping Head A Capping Head is an essential component in packaging machinery, used to securely seal bottles, jars, and other containers with various types of caps, ensuring product integrity and safety. |

|

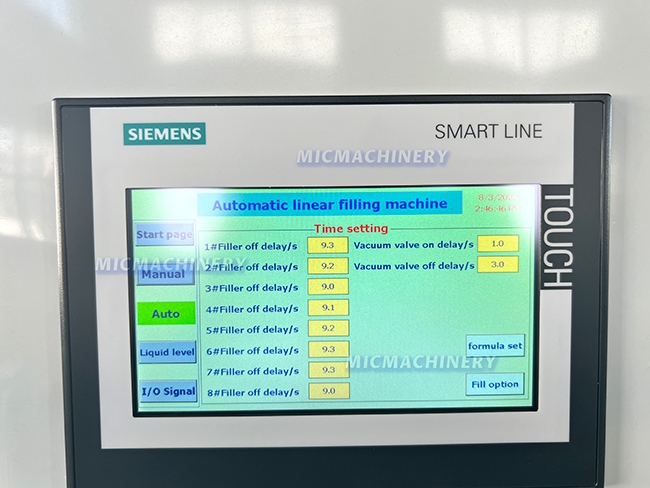

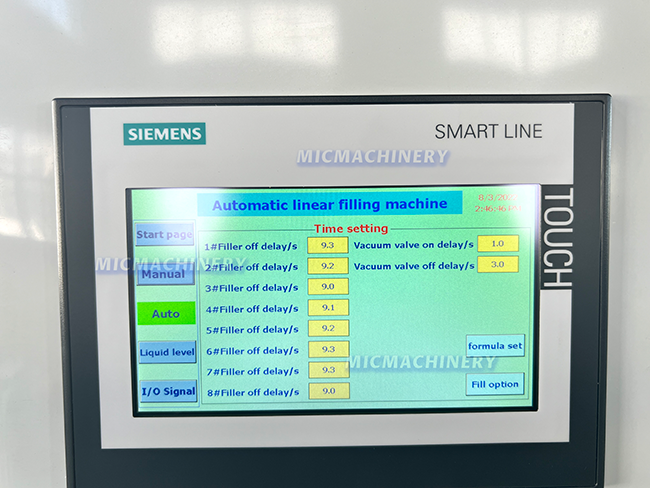

Control panel A Control Panel is a user interface in machinery that allows operators to monitor and control machine functions, adjusting settings for optimal performance, safety, and efficiency in production.

|

|

|

|

Filling Head A Filling Head is a key component in filling machinery, responsible for accurately dispensing liquids or powders into containers. It ensures precise filling levels, improving efficiency and minimizing waste during production. |

Working Principle of Carbonated Filling Machine

The carbonated filling machine operates on the isobaric filling principle, which ensures that carbonation is maintained during the filling process. The machine fills the bottles under constant pressure, preventing the loss of carbonation, ensuring each beverage retains its fizziness and taste. The semi-automatic operation allows for flexibility, with the operator manually placing the bottles into the machine, while the system controls the filling process. The process begins with bottle cleaning and sterilization, followed by filling the bottles with carbonated beverages to the desired level. The bottles are then sealed, maintaining the carbonation and ensuring the beverage is ready for distribution.

Advantages of Carbonated Filling Machine

The MIC Semi-Automatic carbonated drink filling machine offers a range of benefits:

1、Cost-Effective

This small carbonated drink filling machine is an affordable solution for businesses with moderate production volumes, offering great value for money without compromising quality.

2、Precision and Efficiency

The machine ensures accurate filling, reducing waste and ensuring that every bottle is filled with the correct volume, while maintaining carbonation levels.

3、Compact Design

Its small footprint makes it a great choice for production lines with limited space, while still offering high functionality.

4、User-Friendly

With its simple semi-automatic operation, the machine is easy for operators to use, reducing training time and increasing productivity.

5、Durable and Hygienic

Built with high-quality stainless steel, the machine is durable and meets hygiene standards, ensuring safe and long-lasting operation.

6、Fast Operation

The machine offers rapid filling cycles, ensuring that the production line remains efficient and can meet growing demands.

7、Versatile

Compatible with various bottle types and sizes, this carbonated drink filling machine is adaptable to your production needs.

This small carbonated drink filling machine is a reliable and efficient choice for any company looking to streamline their beverage production, while maintaining high standards of quality and productivity.

| Power | 0.3Kw |

| Filling heads | 4-10 heads |

| Capping heads | 4-10 heads |

| Production capacity | 200-800CPH |

| Bottle diameter range | Ф50-90MM |

| Bottle height | 150-300MM |

| Dimension | 2000*700*2000mm |

| Weight | 150Kg |

|

1 |

Name |

Brand |

|

2 |

Push Button |

Schneider France |

|

3 |

Electromagnetic Contactor |

Schneider France |

|

4 |

Relays |

Omron Japan |

|

5 |

Frequency Converter |

Siemens |

|

6 |

Air Cylinder |

AirTAC Taiwan |

|

7 |

Electromagnetic Valve |

AirTAC Taiwan |

|

8 |

PLC Control System |

Siemens |

|

9 |

Touch Screen |

Siemens |

|

10 |

Photoelectric Switch |

Autonics |

|

11 |

Proximity Switch |

Autonics |

|

12 |

Reducer |

Zhejiang Duoli China |

|

13 |

Sealing Motor |

Zhejiang Duoli China |

|

14 |

Barometer |

AirTAC Taiwan |

|

15 |

Bearing |

Harbin China |