Semi Automatic Juice Pouch Filling Machine

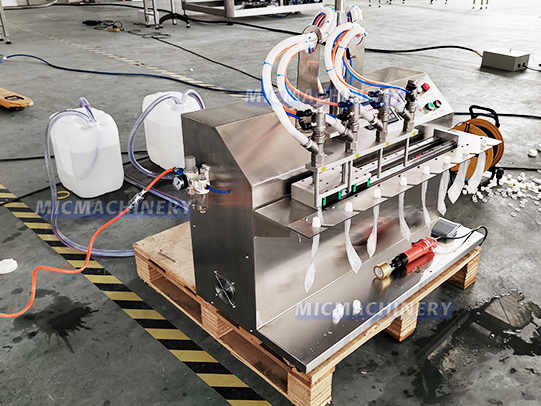

Equipment Introduction: Semi Automatic Juice Pouch Filling Machine

Jiangsu Mic Machinery’s Semi Automatic juice pouch filling machine is a versatile, cost-effective solution designed to meet the needs of small to medium-scale juice production lines. This machine combines manual operation with automated functionality, offering a practical solution for producers who require a balance between flexibility and efficiency. It is ideal for businesses seeking a high-quality juice pouch filling machine without the need for large capital investment.

The juice pouch filling and sealing machine is designed to fill juice pouches with high precision, ensuring the correct volume is dispensed into each pouch. Its semi-automatic nature means that while certain aspects of the operation (such as filling and sealing) are automated, the pouch placement and removal can be managed manually, providing greater control for operators. The juice packet machine is perfect for those looking for an efficient, reliable, and scalable solution to meet production demands while maintaining consistent quality.

|

|

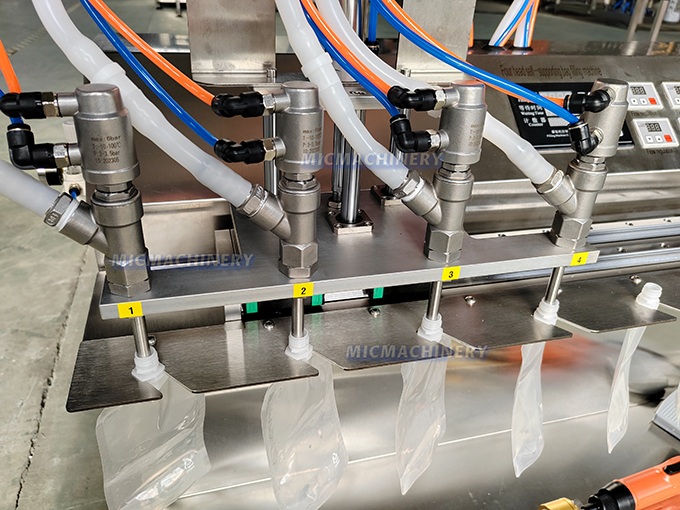

Filling tube A Filling Tube is a critical component in liquid filling machines, directing the flow of liquids into containers. It ensures smooth, accurate filling, preventing spills and optimizing production efficiency. |

|

Touch screen panel A Touch Screen Panel is an intuitive interface used to control and monitor machinery. It allows users to easily adjust settings, access real-time data, and streamline operations with a simple touch interface. |

|

|

|

Filling heads Filling Heads are essential components in automated filling systems, designed to precisely dispense liquids or powders into containers. They ensure accurate volume control, enhance efficiency, and reduce product waste. |

Workflow of the Semi Automatic Juice Pouch Filling Machine

The workflow of the juice pouch filling machine is streamlined for efficiency, combining ease of use with high precision. The process begins with the manual placement of empty pouches onto the machine’s platform. Once in position, the machine’s automated filling station dispenses the correct amount of juice into each pouch. After filling, the juice pouch filling and sealing machine automatically seals the pouch to ensure a tight, secure closure, ready for storage or distribution.

Pouch Placement: The operator manually places empty pouches onto the filling machine.

Filling: The machine’s automated filling mechanism dispenses the desired amount of juice into each pouch with high precision.

Sealing: The juice packet machine automatically seals the pouch, ensuring a secure and hygienic closure to prevent leakage.

Removal: The operator manually removes the filled and sealed pouches, ready for packaging or shipment.

This workflow minimizes manual labor while maintaining flexibility and control over production.

Advantages of the Semi Automatic Juice Pouch Filling Machine

The juice pouch filling machine offers numerous advantages for businesses looking for an efficient, reliable, and economical packaging solution:

1、Cost-Effective

The semi-automatic design reduces initial investment and operating costs, making it ideal for small to medium-scale operations.

2、Precision and Accuracy

The machine ensures consistent and accurate filling of each pouch, minimizing waste and ensuring product quality.

3、Flexibility

The semi-automatic nature of the juice pouch filling and sealing machine allows for customization in production. Operators can adjust filling volumes or pouch sizes, providing greater flexibility in meeting market demands.

4、Reduced Labor Costs

With automation handling the bulk of the process, businesses can reduce their reliance on manual labor, leading to savings in labor costs while increasing operational efficiency.

5、Compact Design

Its compact size makes it easy to integrate into existing production lines without requiring significant space, making it ideal for businesses with limited floor space.

6、Hygienic and Easy to Clean

Designed with food-grade materials, the juice packet machine ensures that the juice remains uncontaminated during the filling and sealing process. Additionally, the machine’s parts are easy to clean and maintain, ensuring consistent hygiene standards.

7、High-Speed Performance

Even with its semi-automatic setup, this machine offers a good filling rate, improving production efficiency without sacrificing quality.

The Semi Automatic juice pouch filling machine from Jiangsu Mic Machinery is the ideal choice for businesses seeking an affordable, flexible, and efficient packaging solution. Whether you’re looking to scale your juice production or maintain consistent quality with a more hands-on approach, this machine provides the perfect balance of automation and control.

|

Filling heads |

6 filling heads |

|

Production speed |

90-100 pouches/min |

|

Suitable pouch |

Spout pouch, doypack |

|

Filling range |

50ml-250ml or 250ml-500ml |

|

Filling precision |

±1-2% |

|

Capping speed |

Match the speed of filling station |

|

Capping heads |

6 capping heads |

|

Voltage |

380V-50hz-3 Phase |

|

Power |

5kw |

|

Air pressure |

0.6Mpa-0.7Mpa |

|

Dimension |

3.5mx2.2m×2m |

|

Weight |

2000kg |

|

1 |

Name |

Brand |

|

2 |

Push Button |

Schneider France |

|

3 |

Electromagnetic Contactor |

Schneider France |

|

4 |

Relays |

Omron Japan |

|

5 |

Frequency Converter |

Siemens |

|

6 |

Air Cylinder |

AirTAC Taiwan |

|

7 |

Electromagnetic Valve |

AirTAC Taiwan |

|

8 |

PLC Control System |

Siemens |

|

9 |

Touch Screen |

Siemens |

|

10 |

Photoelectric Switch |

Autonics |

|

11 |

Proximity Switch |

Autonics |

|

12 |

Reducer |

Zhejiang Duoli China |

|

13 |

Sealing Motor |

Zhejiang Duoli China |

|

14 |

Barometer |

AirTAC Taiwan |

|

15 |

Bearing |

Harbin China |