MIC 12-1 Isobaric Pressure Can Filler (1000-2000CPH)

Introduction to the MIC 12-1 Isobaric Pressure Can Filler (1000-2000CPH)

Jiangsu Mic Machinery is proud to present the MIC 12-1 Isobaric Pressure Can Filler, designed for high-efficiency, high-precision filling of carbonated beverages. Perfect for medium-scale production lines, this can filler is engineered to handle a variety of products, offering reliable and consistent filling at speeds ranging from 1000 to 2000 cans per hour (CPH).

|

|

Aluminum lid seaming system |

|

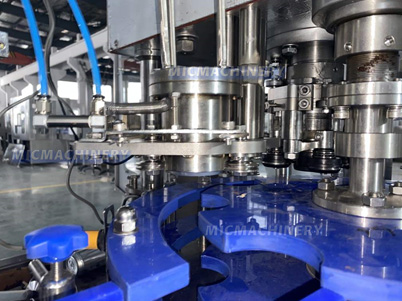

Isobaric pressure / counter pressure filling system The 12-1 isobaric counter pressure filling system is specifically designed for aluminum cans, ensuring a smooth filling process without foaming—provided the beer temperature remains below 40°F. This system maintains a standard 1.27 cm headspace, complying with can manufacturers’ requirements to accommodate product expansion during distribution. Our filling method minimizes dissolved oxygen (DO) levels in the can, preserving product quality. Built with a high-grade 304 food-grade stainless steel tank and precision buffing, the unit ensures hygiene and durability. A CIP connection can be added upon request to support automated cleaning protocols. |

|

|

|

|

Features of the MIC 12-1 Isobaric Pressure Can Filler

The MIC 12-1 Isobaric Pressure Can Filler utilizes advanced isobaric filling technology, which ensures precise filling while maintaining the carbonation levels of the beverage. By matching the pressure inside the can with the pressure of the liquid, the machine minimizes foam formation and reduces product loss during the filling process. This makes the can filling machine ideal for carbonated drinks like soda, beer, and sparkling water.

The aluminum can filling machine is equipped with multiple stations that allow for simultaneous filling, capping, and other essential processes. This design ensures minimal downtime and maximum productivity. Its versatility allows it to handle a variety of can sizes, making it adaptable to the specific needs of the production line.

Advantages of the MIC 12-1 Isobaric Pressure Can Filler

1、High Efficiency and Consistency

The can filler operates at speeds ranging from 1000 to 2000 cans per hour, providing fast, efficient filling while ensuring consistent results across each cycle. This high throughput helps businesses keep up with growing demand.

2、Precise Filling and Minimal Foam

Thanks to the isobaric pressure system, the can filling machine delivers highly accurate fill levels with minimal foam formation. This reduces waste, improves product quality, and enhances the overall efficiency of the production line.

3、Durable and Long-lasting

Built with stainless steel and other high-quality materials, the aluminum can filling machine is resistant to wear and corrosion, ensuring long-term durability even under continuous operation.

4、Reduced Product Loss

The precise filling mechanism and pressure control minimize product loss during filling, helping businesses maintain high yield rates and reduce operational costs.

5、Flexible and Easy to Operate

With user-friendly controls and easy adjustments, the MIC 12-1 Isobaric Pressure Can Filler is simple to operate and maintain. Its flexibility makes it ideal for both small and large production volumes.

In summary, the MIC 12-1 Isobaric Pressure Can Filler is a high-performance, efficient solution for carbonated beverage filling. Its precise filling mechanism, minimal foam production, and durability make it a valuable asset for any production line looking to boost productivity while maintaining high-quality standards. At Jiangsu Mic Machinery, we are committed to providing innovative solutions that meet the unique needs of our customers, ensuring that every filling operation runs smoothly and efficiently.

MIC 12-1 Parameters

| Power | 1.1Kw |

| Filling heads | 12piece |

| Sealing heads | 1piece |

| Production capacity |

1000-2000CPH based on 330ml |

| Filling temperature | 0-4 ℃ |

| Filling pressure | Max 5bar/0.5Mpa |

| Can diameter range | Ф40-90MM |

| Can height | 92-168MM |

| Dimension |

1800*1300*1950mm |

| Weight | 1800Kg |

More Model and Speed Click

| Model | MIC 12-1 | MIC 18-1 | MIC 18-6 | MIC 24-6 | MIC 32-8 |

| Application | Beer, Carbonated Beverage, Gas Drinks, Cold Coffee, Sparking Water, Cider, Soda Water, Herbal Tea, Non-Carbonated Drinks And So On | ||||

| Packing Type | Aluminum Cans, Metal Cans, Tin Cans, Pet Cans Etc | ||||

| Speed | 1000-2000CPH | 1000-2500CPH | 3000-6000CPH | 4000-8000CPH | 6000-10000CPH |

| Filling Arrange | 180ml, 250ml, 330ml, 355ml, 440ml, 500ml, 8oz, 12oz, 16oz, 1L and so on (0.1-1L) | ||||

| Power | 1.1kw | 1.5kw | 2.5kw | 3.5kw | 4.2kw |

| Size | 1.8*1.3*1.95 (M) | 1.9*1.3*1.95(M) | 2.3*1.4*1.9(M) | 2.58*1.7*1.8(M) | 2.8*1.7*1.95(M) |

| Weight | 1800KG | 2100KG | 2500KG | 3000KG | 3800(KG) |

|

1 |

Name |

Brand |

|

2 |

Push Button |

Schneider France |

|

3 |

Electromagnetic Contactor |

Schneider France |

|

4 |

Relays |

Omron Japan |

|

5 |

Frequency Converter |

Siemens |

|

6 |

Air Cylinder |

AirTAC Taiwan |

|

7 |

Electromagnetic Valve |

AirTAC Taiwan |

|

8 |

PLC Control System |

Siemens |

|

9 |

Touch Screen |

Siemens |

|

10 |

Photoelectric Switch |

Autonics |

|

11 |

Proximity Switch |

Autonics |

|

12 |

Reducer |

Zhejiang Duoli China |

|

13 |

Sealing Motor |

Zhejiang Duoli China |

|

14 |

Barometer |

AirTAC Taiwan |

|

15 |

Bearing |

Harbin China |